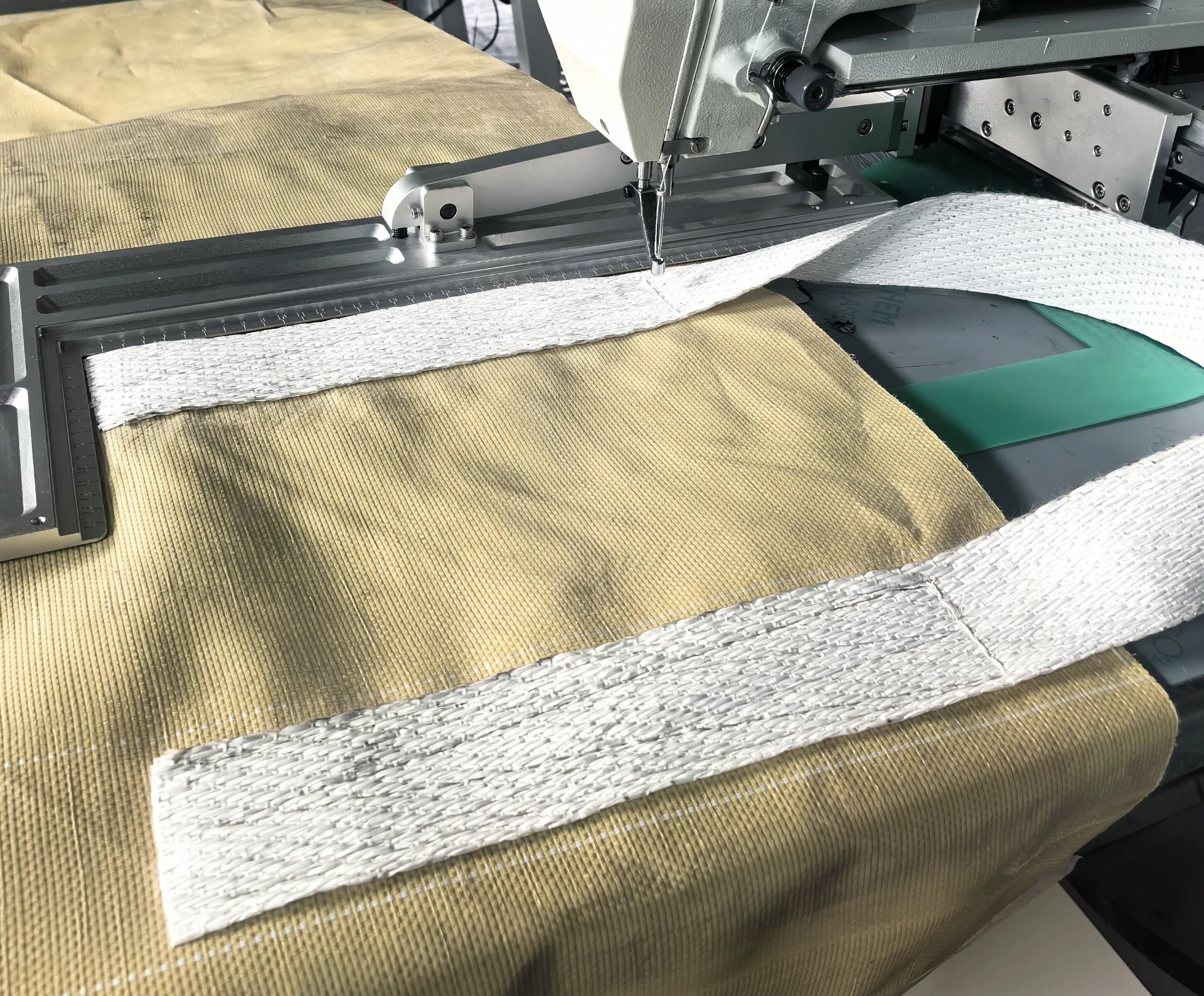

lock stitch machine

Understanding the Lock Stitch Machine A Key Player in Textile Production

In the world of textile manufacturing, efficiency, precision, and versatility are fundamental elements that determine the success of textile production. Among the various sewing technologies, the lock stitch machine stands out as one of the most essential pieces of equipment used in garment production and various other textile applications.

What is a Lock Stitch Machine?

The lock stitch machine is a type of sewing machine that creates a stitch by interlocking two threads—one from the needle and one from the bobbin. This method forms a strong and secure stitch, which is ideal for many fabric types. Unlike chain stitch machines, which create a stitch with a single thread loop, lock stitch machines utilize a dual-thread system that creates a flat and durable seam on the fabric’s surface.

Mechanics of the Lock Stitch

Understanding the mechanics of a lock stitch machine is crucial for anyone involved in the textile industry. The basic components of this machine include the needle, hook, bobbin, and feed dogs. When the needle penetrates the fabric, it also pushes the upper thread through the material. As the needle reaches its lowest point, the hook catches the upper thread and forms a loop around the bobbin thread. When the needle rises, it pulls the upper thread back, sealing the loop around the bobbin thread and creating a tight stitch.

The simplicity and reliability of the lock stitch mechanism contribute to its popularity. Moreover, it allows for various adjustments, such as stitch length and tension controls, making it adaptable for different sewing requirements.

Applications in Textiles

The lock stitch machine is utilized in an array of applications within the textile industry. Its primary function is to assemble garments by sewing together multiple fabric pieces. This machine is commonly used for sewing seams in shirts, trousers, dresses, and a wide variety of other clothing items.

Additionally, the lock stitch is ideal for decorative stitching, hemming, and topstitching, and it is widely employed in making lightweight to medium-weight fabrics. The precision of the lock stitch ensures that the seams are not only strong but also aesthetically pleasing, which is crucial in the fashion industry.

lock stitch machine

Beyond garment manufacturing, lock stitch machines also find utilization in various other sectors

. For instance, they are used in leather goods production, upholstery, and even in the production of specialized fabrics like tents and awnings, where durability is a top priority.Advantages of Lock Stitch Machines

Several advantages make lock stitch machines a preferred choice for manufacturers. Firstly, the interlocking nature of the lock stitch creates a seam that is less likely to unravel compared to other types of stitching. This characteristic is especially important in industries demanding long-lasting durability in their products.

Secondly, lock stitch machines are generally easier to operate and maintain compared to more complex sewing machines. They are widely available and come in various models, catering to different production needs and budgets.

Moreover, advancements in technology have led to the development of computerized lock stitch machines, which enhance efficiency and allow for greater precision in stitching, further streamlining production processes.

Maintenance and Care

Proper maintenance of lock stitch machines is essential to ensure their longevity and to maintain optimal performance. Regular cleaning to remove dust and lint build-up, oiling the moving parts, and checking the tension of the threads are some of the critical maintenance practices every operator should adhere to.

Additionally, ensuring that the machine is correctly threaded and that the needles and bobbins are appropriate for the fabric being used can prevent most sewing issues and keep the machine functioning smoothly.

Conclusion

The lock stitch machine remains a fundamental tool in the textile industry. Its unique ability to produce strong and reliable stitching makes it indispensable in a variety of applications. As technology continues to evolve, so too will the capabilities of lock stitch machines, ensuring they remain at the forefront of sewing technology for years to come. For manufacturers, understanding and leveraging the advantages of the lock stitch machine can significantly enhance production efficiency and product quality, ultimately leading to greater customer satisfaction and business success.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025