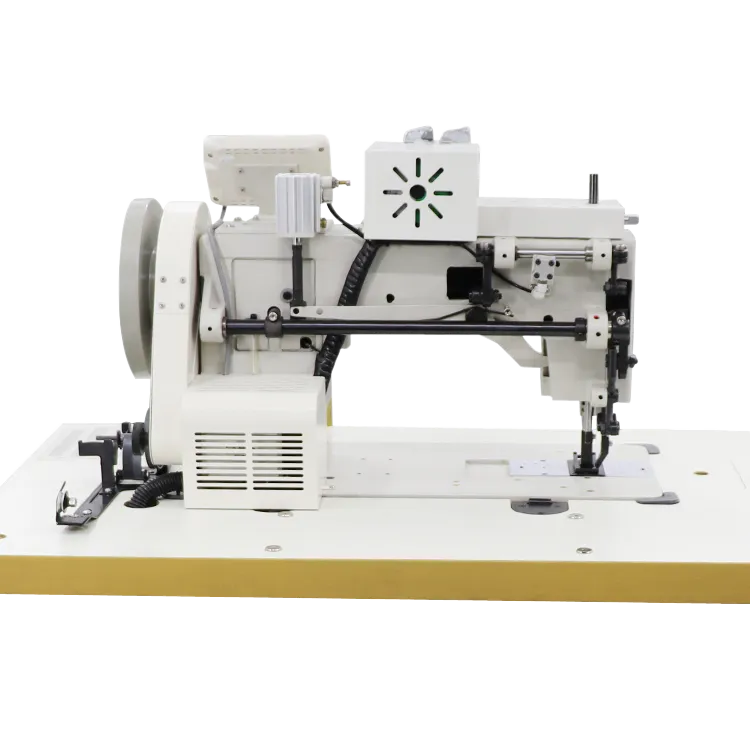

double needle lockstitch machine

Understanding the Double Needle Lockstitch Machine

The double needle lockstitch machine is a crucial piece of equipment in the textile and garment manufacturing industry. Known for its efficiency and versatility, this machine has become a staple for professional sewing operations, allowing manufacturers to create high-quality stitched products with precision and reliability. This article will explore the features, applications, advantages, and maintenance aspects of the double needle lockstitch machine.

Features

The double needle lockstitch machine operates using two needles that work simultaneously, creating two parallel rows of stitching. This setup allows for a more decorative and functional seam, which is particularly beneficial in applications requiring durability or visual appeal. The machine utilizes a lockstitch mechanism, where the thread from the upper needle interlocks with the bobbin thread beneath the fabric. This creates a strong seam that can withstand stress and use.

One of the key components of this machine is its ability to handle various types of fabrics, from lightweight materials like cotton to heavier fabrics such as denim or canvas. This versatility is enhanced by adjustable tension settings, which allow operators to fine-tune the machine for different fabric types and thicknesses. Additionally, modern double needle lockstitch machines often come equipped with advanced features such as automatic thread trimming, programmable stitch lengths, and digital displays, improving productivity and ease of use.

Applications

The applications of the double needle lockstitch machine are wide-ranging. In the apparel sector, it is commonly used for stitching jeans, shirts, and blouses, where both strength and aesthetic appeal are vital. The double needle sewing technique is favored in creating decorative hems, topstitching, and certain design elements that require precision.

Moreover, this machine is also employed in industries beyond clothing, including upholstery, automotive interiors, and even leather goods. Its ability to produce two parallel stitches makes it ideal for reinforcing seams in products that undergo significant wear and tear. As a result, manufacturers in various sectors have adopted this equipment to enhance the durability and quality of their products.

double needle lockstitch machine

Advantages

One of the most significant advantages of using a double needle lockstitch machine is the enhanced seam strength it provides. With two threads interlocking, the seams are less likely to fray or break, which is essential in high-stress applications. Additionally, the aesthetic appeal of double-stitched seams adds a professional finishing touch to garments and products, which can improve their marketability.

Another advantage is the machine's speed and efficiency. Operators can complete a large volume of stitching in a relatively short time, making it an ideal choice for production environments. The ability to work with various fabric types also means that manufacturers can produce a diverse range of products without needing multiple machines, saving both space and investment costs.

Maintenance

Proper maintenance of the double needle lockstitch machine is crucial to ensure its longevity and optimal performance. Regular cleaning is essential to prevent dust and lint buildup, which can affect the machine's operation. Operators should also check the tension settings regularly, as incorrect tension can lead to poor stitching quality.

Lubrication of moving parts is another critical maintenance task. Regularly oiling the machine will keep it running smoothly and reduce wear and tear. Additionally, it’s essential to replace needles regularly, especially when working with thick fabrics, to maintain the quality of stitching.

Conclusion

In conclusion, the double needle lockstitch machine is an invaluable asset in the sewing industry, offering a robust solution for creating strong, decorative seams. Its versatility, speed, and aesthetic advantages make it essential for various applications, from clothing manufacturing to upholstery. By understanding its features and proper maintenance practices, manufacturers and operators can maximize their investment and ensure the machine operates efficiently for years to come. Whether you’re a small-scale artisan or a large-scale manufacturer, the double needle lockstitch machine can elevate your production capabilities and enhance the quality of your products.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025