فبراير . 10, 2025 11:09

Back to list

what is a cylinder arm sewing machine used for

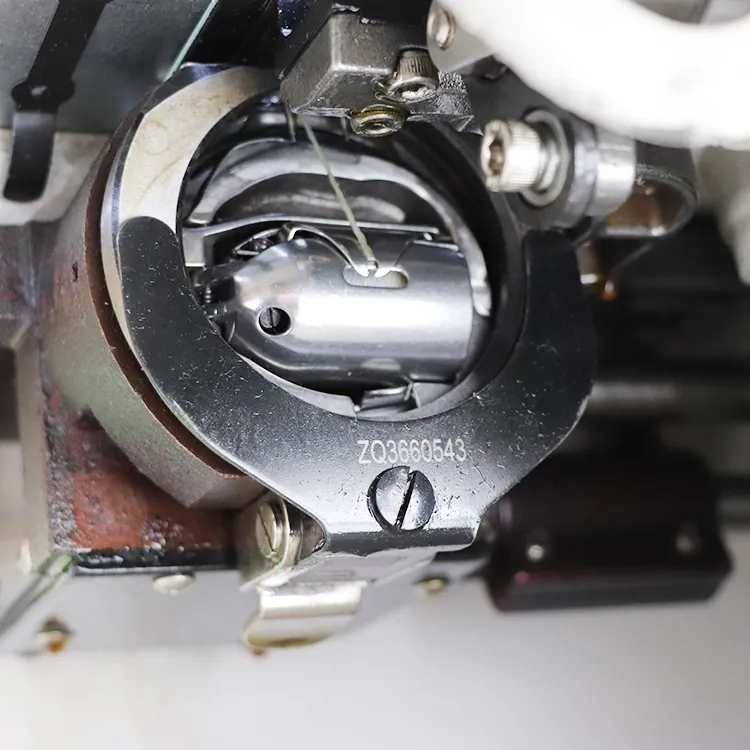

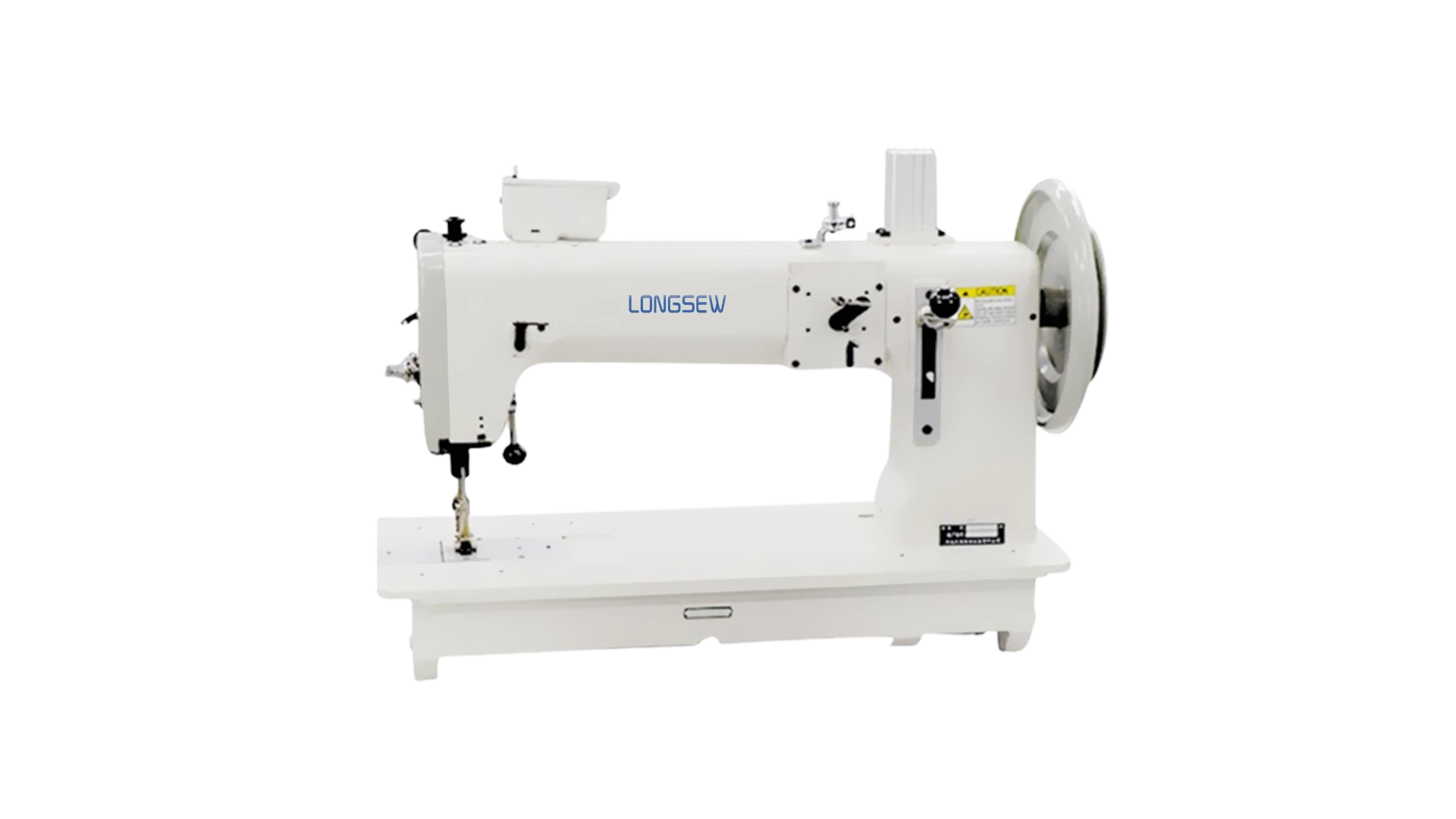

Cylinder arm sewing machines represent a unique and essential tool in the professional sewing and textile industry. These machines are characterized by their distinctive, rounded arm, which protrudes from the main body of the device, allowing for unparalleled flexibility and precision when working on intricate projects. Their design solves many challenges faced in sewing, granting professionals and hobbyists alike the ability to sew on three-dimensional objects such as bags, hats, shoes, and cylindrical items, which are often cumbersome or impossible to handle with traditional flatbed sewing machines.

The investment in a cylinder arm sewing machine is one that can expand the capacity and capability of a workshop. With its specialized design, it attracts industries and individual artists looking to diversify their product offerings. Workshop owners can leverage these machines to differentiate themselves in the marketplace by creating custom, high-quality products that would otherwise be difficult to achieve. Whether it's adding a personal touch to handcrafted goods or meeting the rigorous standards required for automotive interiors, these machines stand at the forefront of innovation and craftsmanship. Furthermore, when selecting a cylinder arm sewing machine, it is essential to consider factors such as the machine's throat space, which dictates the maximum size of the project it can accommodate, the motor power, which affects the machine's ability to handle heavier materials, and the availability of attachments that can provide added flexibility. There is a wide range of models available, from industrial giants to more compact versions suited for smaller studios, each offering its own set of features tailored to specific needs. Despite their unique advantages, transitioning to using a cylinder arm sewing machine may present a learning curve. Users accustomed to flatbeds must adapt to the machine’s handling and orientation. Fortunately, numerous online resources and communities can facilitate this transition, offering guides, tutorials, and support for both novice and experienced operators. Investing time to master these machines can result in substantial skill development and open new avenues for creativity and business growth. Ultimately, the true value of a cylinder arm sewing machine lies in its ability to enhance the sewing experience through advanced features, superior control, and unwavering reliability. These qualities make it a worthy addition to any professional's toolkit, promoting not only productivity but also a pursuit of excellence in every stitch.

The investment in a cylinder arm sewing machine is one that can expand the capacity and capability of a workshop. With its specialized design, it attracts industries and individual artists looking to diversify their product offerings. Workshop owners can leverage these machines to differentiate themselves in the marketplace by creating custom, high-quality products that would otherwise be difficult to achieve. Whether it's adding a personal touch to handcrafted goods or meeting the rigorous standards required for automotive interiors, these machines stand at the forefront of innovation and craftsmanship. Furthermore, when selecting a cylinder arm sewing machine, it is essential to consider factors such as the machine's throat space, which dictates the maximum size of the project it can accommodate, the motor power, which affects the machine's ability to handle heavier materials, and the availability of attachments that can provide added flexibility. There is a wide range of models available, from industrial giants to more compact versions suited for smaller studios, each offering its own set of features tailored to specific needs. Despite their unique advantages, transitioning to using a cylinder arm sewing machine may present a learning curve. Users accustomed to flatbeds must adapt to the machine’s handling and orientation. Fortunately, numerous online resources and communities can facilitate this transition, offering guides, tutorials, and support for both novice and experienced operators. Investing time to master these machines can result in substantial skill development and open new avenues for creativity and business growth. Ultimately, the true value of a cylinder arm sewing machine lies in its ability to enhance the sewing experience through advanced features, superior control, and unwavering reliability. These qualities make it a worthy addition to any professional's toolkit, promoting not only productivity but also a pursuit of excellence in every stitch.

Previous:

Latest news

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025