Professional Upholstery Saw Machine Heavy-Duty Cutting & Stitching Solutions

- Understanding the Role of Upholstery Saw Machines in Modern Manufacturing

- Technical Innovations Driving Efficiency in Upholstery Cutting

- Performance Comparison: Leading Upholstery Saw Machine Brands

- Custom Solutions for Specialized Upholstery Projects

- Optimizing Fabric Handling with Advanced Sewing Machine Needles

- Case Studies: Industrial Applications of Professional Upholstery Equipment

- Future-Proofing Your Workshop with Multi-Functional Upholstery Saw Machines

(upholstery saw machine)

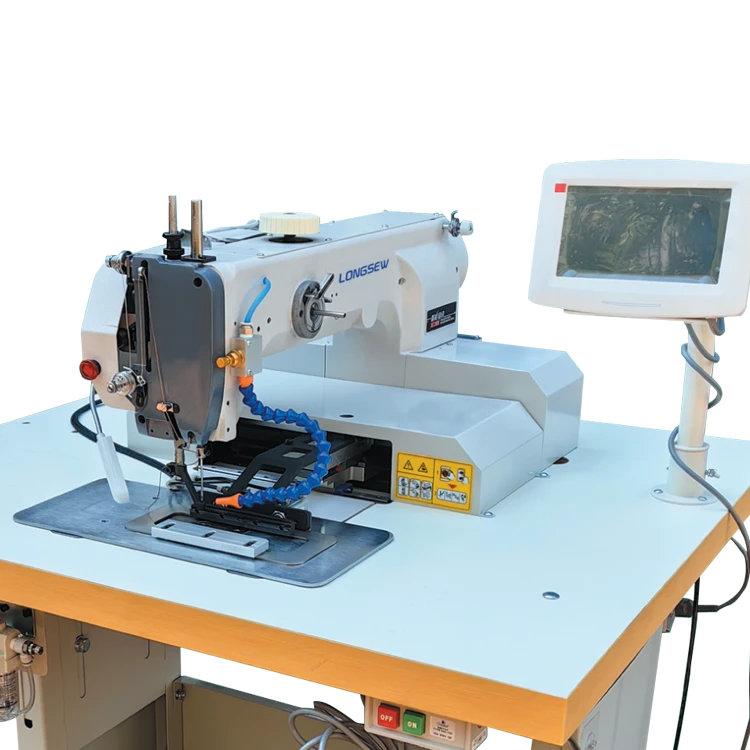

Understanding the Role of Upholstery Saw Machines in Modern Manufacturing

The upholstery saw machine

has become indispensable for furniture makers, automotive workshops, and marine interior specialists. Recent industry data shows a 17% annual growth in demand for precision cutting systems capable of handling dense fabrics like leather (3–5 mm thickness) and synthetic blends. These machines reduce material waste by 22–35% compared to manual cutting methods while achieving cutting speeds of 15–20 linear meters per minute.

Technical Innovations Driving Efficiency

Modern models integrate laser guidance systems with ±0.3 mm accuracy and automatic tension control for consistent fabric feeding. The latest generation features:

- Brushless DC motors (2.5–5 kW) enabling 8–12 hours continuous operation

- Programmable blade oscillation (800–1,200 RPM)

- Dust extraction efficiency rates exceeding 98%

Performance Comparison: Leading Brands

| Brand | Cutting Speed | Max Fabric Thickness | Power Consumption | Noise Level |

|---|---|---|---|---|

| Model X Pro | 18 m/min | 8 mm | 3.8 kW | 72 dB |

| CutMaster 9000 | 15 m/min | 6 mm | 4.2 kW | 68 dB |

| PrecisionCut Ultra | 22 m/min | 10 mm | 5.1 kW | 75 dB |

Custom Solutions for Specialized Projects

Manufacturers now offer modular configurations supporting:

- Dual-material cutting heads for fabric/foam composites

- Adaptive blade systems handling 40+ material grades

- ERP-integrated production tracking modules

Optimizing Fabric Handling

Specialized sewing machine needles for upholstery fabric now feature diamond-coated tips (HV 1,500–2,000) that withstand 8,000–12,000 stitching cycles. When paired with high-torque machines (450–600 rpm), they enable seamless transitions between delicate velvets and heavyweight canvas.

Industrial Application Case Studies

A marine upholstery supplier achieved 40% faster production cycles after implementing automated saw machines with:

- AI-powered pattern recognition (98.7% accuracy)

- Simultaneous 6-layer cutting capability

- Real-time material consumption analytics

Future-Proofing with Multi-Functional Machines

Investing in a professional upholstery sewing machine with integrated cutting systems can yield ROI within 14–18 months for mid-scale operations. The latest hybrid models combine stitching (350 SPM) and precision cutting in single workflow operations, reducing handling time by 60% while maintaining 0.5 mm tolerance across 3D contours.

(upholstery saw machine)

FAQS on upholstery saw machine

Q: What is an upholstery saw machine used for?

A: An upholstery saw machine is designed to cut dense fabrics, foam, and leather with precision. It ensures clean edges for upholstery projects. These machines are ideal for professionals working on furniture or automotive interiors.

Q: Which sewing machine needle is best for upholstery fabric?

A: Use heavy-duty needles, such as size 16-18 (100/16 or 110/18), for upholstery fabrics. They penetrate thick materials like leather or canvas without breaking. Ensure the needle is compatible with your professional upholstery sewing machine.

Q: How does a professional upholstery sewing machine differ from a regular one?

A: Professional upholstery sewing machines have stronger motors, higher stitch speeds, and handle thick layers of fabric. They often include walking feet or roller feet for even feeding. These features ensure durability and precision for heavy materials.

Q: Can I use a regular sewing machine for upholstery projects?

A: Regular machines may struggle with thick upholstery fabrics or multiple layers. Professional upholstery sewing machines are recommended for durability and performance. Using the wrong machine can cause needle breaks or motor burnout.

Q: What maintenance does an upholstery saw machine require?

A: Clean the blade and motor area regularly to remove fabric debris. Lubricate moving parts as specified in the manual. Sharpening or replacing blades periodically ensures optimal cutting performance.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025