Single Needle Sewing Machine for Industrial Applications and Precision Stitching Solutions

The Single Needle Industrial Sewing Machine A Cornerstone of Modern Textile Production

In the realm of textile manufacturing, the single needle industrial sewing machine stands out as one of the most essential tools in the industry. Its design, functionality, and versatility make it a cornerstone for garment production, catering to a wide range of fabrics and sewing applications. Understanding its significance and operation provides valuable insights into the world of industrial sewing.

At the heart of the single needle sewing machine lies its straightforward yet effective design. This machine typically features one needle that stitches fabric layers together using a lockstitch mechanism. This means that it creates a stitch by interlocking the upper thread with the lower thread, providing a tight and secure seam. The simplicity of its mechanism, combined with its robust construction, allows it to handle continuous hours of operation, making it ideal for mass production environments.

One of the primary advantages of the single needle industrial sewing machine is its versatility. It is capable of sewing a variety of fabrics, from lightweight materials like silk to heavier fabrics such as denim or canvas. This adaptability allows manufacturers to utilize a single piece of equipment for multiple projects, minimizing the need for different machines dedicated to specific tasks. This not only saves on costs but also streamlines the production process, allowing for greater efficiency and flexibility.

Moreover, the single needle sewing machine is commonly used for several applications, including straight stitching, topstitching, and hemming. It is particularly advantageous for producing high-quality seams that are visually appealing and structurally sound. Manufacturers often rely on this machine for assembling garments, as its precision ensures that the seams are uniform and consistent.

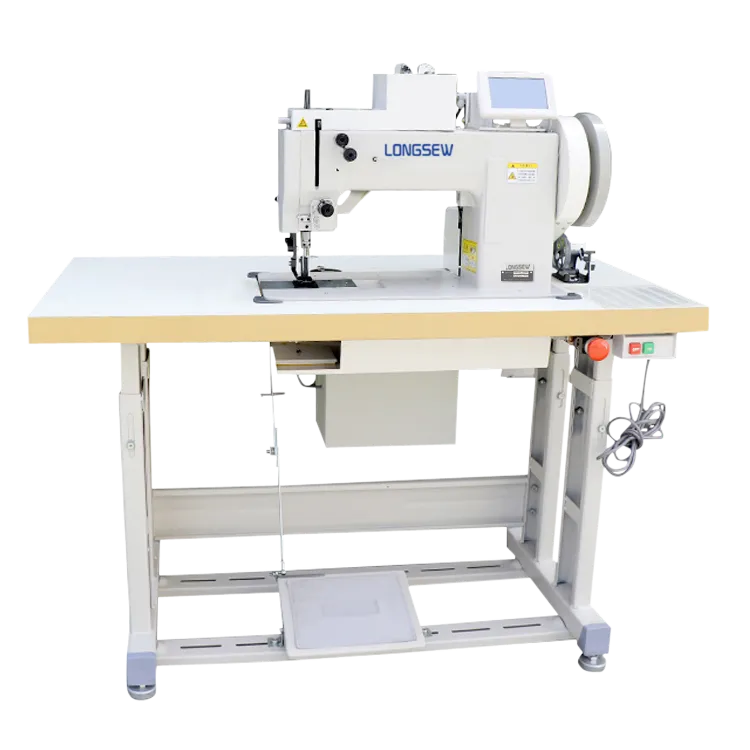

single needle industrial sewing machine

In addition to its functional features, the single needle industrial sewing machine is also equipped with various modern enhancements. Advancements in technology have integrated electronic controls, allowing for adjustments in speed, stitch length, and tension with ease. This has resulted in improved accuracy and a higher level of customization in garment production. For instance, operators can fine-tune settings to accommodate different fabric types and thicknesses, ensuring optimal results and minimizing the likelihood of defects.

Maintenance and care are also crucial for the longevity and performance of these machines. Regular cleaning, lubrication, and timely servicing can prevent issues that may disrupt production and lead to costly downtimes. Additionally, operators must receive adequate training to operate the machine efficiently and safely. Knowledge of its parts, functions, and troubleshooting techniques can greatly increase productivity and ensure high-quality outputs.

While the single needle industrial sewing machine is a staple in traditional sewing environments, its role is evolving in the face of newer technologies. The rise of automated sewing solutions and computer numerical control (CNC) machines has introduced new dynamics to textile manufacturing. However, the single needle machine continues to hold its ground due to its reliability and the artisanal quality it brings to garment production. It remains an invaluable asset for small to medium-sized manufacturers who may not require the extensive capabilities of highly automated systems.

In conclusion, the single needle industrial sewing machine plays an indispensable role in the textile industry. Its simplicity, versatility, and efficiency make it a staple in garment production, providing manufacturers with the ability to produce high-quality products consistently. As the industry continues to evolve, the single needle machine will undoubtedly remain a pivotal component, balancing traditional craftsmanship with modern technological advancements. This machine not only reflects the evolution of textile manufacturing but also embodies the commitment to quality and precision that defines the industry. As we look to the future, the single needle sewing machine will continue to be a symbol of functionality and durability, serving the needs of manufacturers and consumers alike.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025