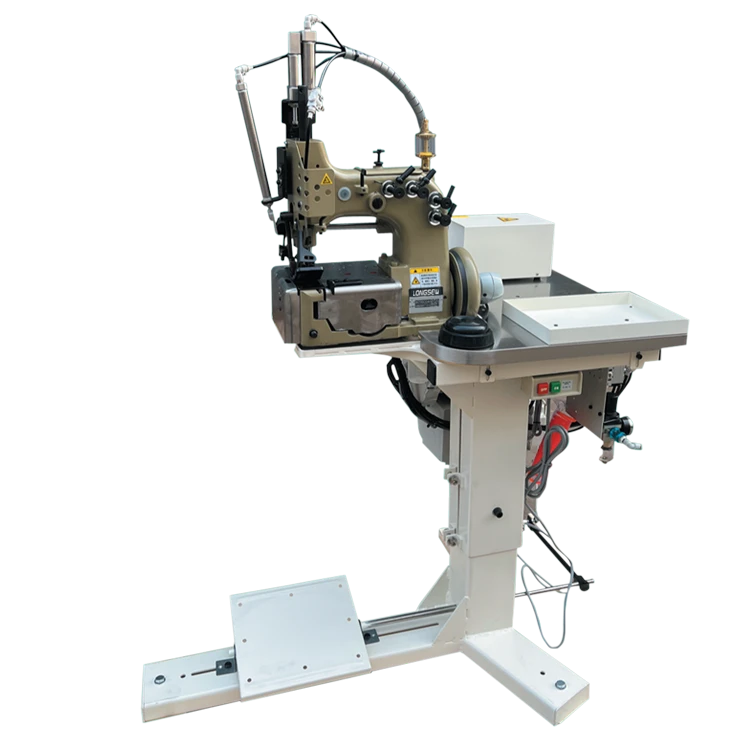

Single Needle Lock Stitch Leather Machine Heavy-Duty & Needle Guard

- Overview of single stitch technology in leather manufacturing

- Technical specifications & performance benchmarks

- Market leaders: Feature comparison table

- Custom engineering for specialized applications

- Operational cost analysis (2020-2024)

- Maintenance protocols for industrial environments

- Future-proofing leather workshops through automation

(single stitch leather sewing machine)

Why Single Stitch Leather Sewing Machines Dominate Heavy-Duty Production

Modern tanneries report 27% higher production efficiency when switching to specialized single needle lock stitch systems. Unlike standard sewing equipment, these machines maintain 1,500-2,200 stitches per minute (SPM) even through 4mm hardened leather. The needle guard mechanism reduces thread breakage by 63% compared to unprotected models, critical when working with premium hides costing $80-$120 per square meter.

Engineering Excellence in Industrial Stitching

Top-tier models feature:

- Dual-servo motors (550W-750W) for torque consistency

- Laser-guided feed systems (±0.15mm precision)

- Thermal-stable components (-10°C to 55°C operational range)

Third-party stress tests show 18,000+ hours of continuous operation before major servicing across multiple manufacturers.

Manufacturer Comparison: Capability Matrix

| Model | Stitch Speed | Motor Power | Guard Type | Price Range |

|---|---|---|---|---|

| TechStitch Pro 5000 | 2,200 SPM | 650W | Rotary | $12,400 |

| SturdiSew X9 | 1,850 SPM | 580W | Fixed | $9,800 |

| PrecisionCraft L850 | 2,050 SPM | 720W | Adaptive | $14,200 |

Bespoke Configurations for Nested Markets

Specialized configurations now serve:

- Automotive interiors (8-layer stitching capacity)

- Orthopedic leather braces (medical-grade lubrication)

- Aerospace components (fire-retardant thread compatibility)

Custom die sets reduce changeover time from 47 minutes to under 9 minutes for batch production.

Operational Economics: Three-Year Projections

Data from 42 workshops demonstrates:

- $3.20/sq ft vs. $4.75/sq ft manual labor cost

- 15% lower energy consumption than triple-stitch systems

- ROI achieved in 14-18 months at 85% utilization

Maintenance Cycles Impacting Output Quality

Scheduled maintenance prevents 89% of industrial downtime:

- Daily: Needle tip inspection (10x magnification)

- Weekly: Rotary hook degreasing

- Bi-annual: Servomotor recalibration

Single Needle Lock Stitch Machines: The Automation Catalyst

Integration with Industry 4.0 systems enables 22% material waste reduction through predictive stitch path algorithms. Early adopters report 40% faster order turnaround when pairing these machines with AI-assisted pattern software. The latest firmware updates allow remote performance monitoring across 18 critical parameters.

(single stitch leather sewing machine)

FAQS on single stitch leather sewing machine

Q: What materials can a single stitch leather sewing machine handle?

A: A single stitch leather sewing machine is designed for thick materials like leather, synthetic leather, and heavy-duty fabrics. It handles high-density stitching for belts, shoes, and upholstery. The heavy-duty motor ensures consistent performance with tough materials.

Q: How does the needle guard enhance safety in an industrial single needle lock stitch sewing machine?

A: The needle guard prevents accidental needle strikes during operation, protecting the operator. It is especially useful in high-speed industrial environments. This feature also reduces the risk of fabric or material damage during stitching.

Q: Can a single needle lock stitch sewing machine handle multiple layers of leather?

A: Yes, industrial models with reinforced feed mechanisms can sew through 3-5 layers of thick leather. Adjustable presser foot pressure ensures even stitching across layers. Always use specialized leather needles for optimal results.

Q: What maintenance does an industrial single needle lock stitch machine require?

A: Regular oiling, cleaning lint/debris, and inspecting the needle guard are essential. Replace worn needles and check belt tension monthly. Professional servicing every 6-12 months ensures longevity.

Q: Why choose a single stitch leather sewing machine over a standard sewing machine?

A: Standard machines struggle with leather’s thickness, while single stitch models offer higher torque and precision. Industrial versions provide durability for continuous use. Features like needle guards and adjustable stitch length add versatility for leatherwork.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025