Durable Sewing Machine for Safety Rope Production and Repair

Safety Rope Sewing Machine Enhancing Safety Standards in Industrial Applications

In various industrial settings, safety is a paramount concern. One significant aspect of safety equipment is the use of safety ropes, which serve crucial roles in preventing accidents and ensuring worker protection. As the demand for high-quality safety ropes increases, so does the need for specialized machinery to manufacture them. Among these, the safety rope sewing machine stands out as an essential tool in producing reliable, robust, and secure safety ropes used across multiple industries.

Safety ropes are commonly utilized in construction, climbing, rescue operations, and maritime applications. They must adhere to stringent safety protocols to withstand extreme conditions, providing users with peace of mind. The manufacturing process of these ropes involves not just strong materials but also precise sewing techniques. This is where safety rope sewing machines become invaluable.

Understanding Safety Rope Sewing Machines

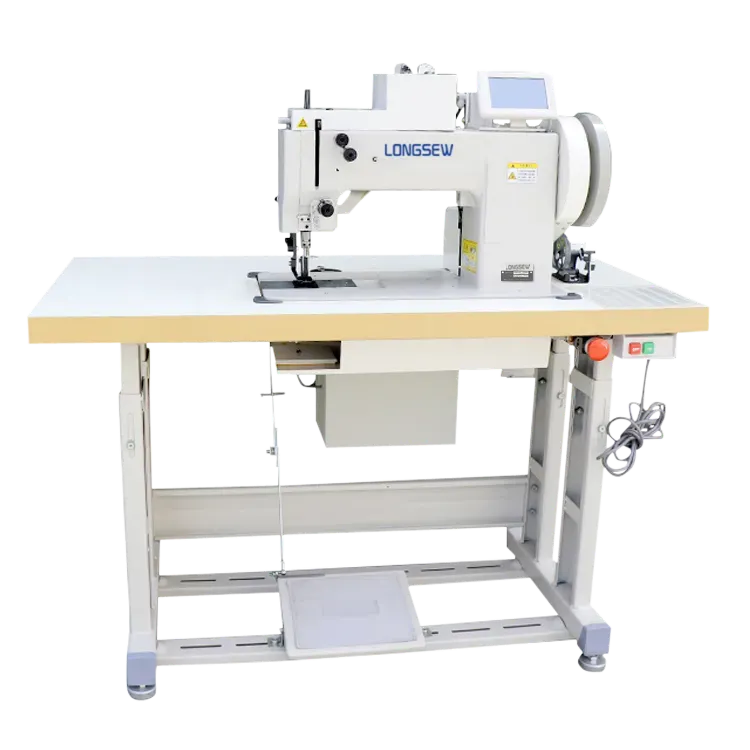

Safety rope sewing machines are designed specifically for sewing high-strength materials such as nylon, polyester, or polypropylene used in safety ropes. Unlike standard sewing machines, these specialized machines are engineered to handle the unique challenges presented by heavy-duty fabrics and thick strands. They feature powerful motors, reinforced frames, and specialized needles that enable them to create durable seams capable of withstanding substantial loads.

The sewing process in manufacturing safety ropes is critical—any flaw can compromise the rope's integrity. Therefore, safety rope sewing machines are equipped with features like tension control, stitch density adjustment, and reinforced stitching capabilities to meet industry standards. Some advanced models even offer computerized systems that allow for precise programming of stitch patterns, ensuring consistency and quality in every product manufactured.

Industry Applications

safety rope sewing machine

The application of safety rope sewing machines spans various sectors. In construction, for example, safety ropes are typically used as fall protection systems that prevent workers from plunging to lower levels. A well-stitched safety rope can mean the difference between life and death. Similarly, in the climbing community, roping systems must be meticulously crafted to endure rigors of dynamic forces during falls.

In rescue operations, safety ropes are also paramount. They are used to secure individuals during rescues from heights or to pull them from dangerous situations. The reliability of these safety ropes hinges on the quality of manufacturing processes, which is why investing in high-quality safety rope sewing machines is vital for companies involved in producing these lifesaving devices.

Quality and Standards

Safety products are subject to rigorous testing and certifications to comply with safety standards set by various regulatory bodies. Manufacturers must ensure that their safety ropes meet these specifications to be marketable and trusted by users. Investing in safety rope sewing machines that allow manufacturers to adhere to these stringent guidelines is not just prudent; it is essential.

Quality control is integral to the manufacturing process. Advanced safety rope sewing machines come with built-in quality assurance features such as automatic thread tension adjustments, which minimize human error that could lead to compromised rope quality. Regular maintenance and calibration of these machines are likewise critical to ensuring they perform optimally, producing ropes that meet or exceed safety regulations.

Conclusion

In conclusion, safety rope sewing machines play an indispensable role in the production of safety ropes across diverse industries. With their ability to handle tough materials, ensure precise stitching, and adhere to strict safety standards, these machines help in manufacturing reliable equipment that protects lives. As industries continue to evolve and safety becomes an even greater focus, the importance of advanced machinery in producing safety-centric products will only grow. By prioritizing invested resources into high-quality safety rope sewing machines, manufacturers can not only enhance their product offerings but also contribute to the overall safety and well-being of workers and end-users around the globe.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025