Polypropylene Bag Stitching Machine for Efficient Packaging Solutions

The Evolution of PP Bag Stitching Machines Enhancing Efficiency in the Packaging Industry

In the ever-evolving landscape of the packaging industry, efficiency and precision are paramount. One of the unsung heroes of this sector is the PP bag stitching machine, a vital tool that ensures bags made from polypropylene (PP) are securely closed, thereby maintaining the integrity of their contents. This article delves into the significance, functionality, and advancements associated with PP bag stitching machines.

Understanding PP Bags

Polypropylene bags are lightweight, durable, and versatile, making them a popular choice for various sectors, including agriculture, food, and construction. Their resistance to moisture and chemicals enhances their utility, while their ease of customization caters to branding needs. However, the effectiveness of PP bags largely hinges on the manner in which they are stitched and sealed, highlighting the importance of stitching machines in the packaging process.

The Role of PP Bag Stitching Machines

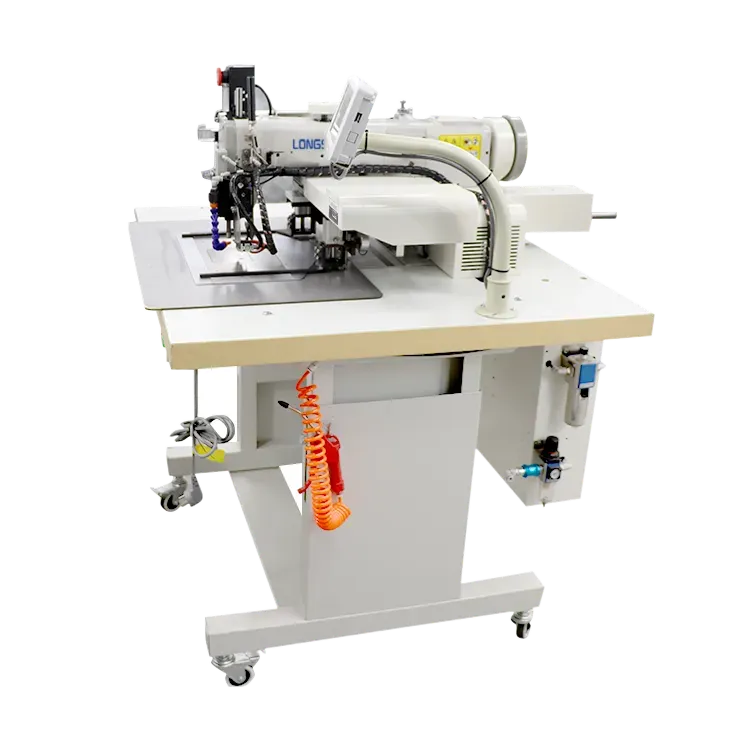

PP bag stitching machines are designed to automate the process of closing open bags with precision and speed. These machines utilize strong threads to stitch the edges of polypropylene bags, ensuring that they can hold substantial weight without tearing. The primary components of these machines include a feeding system, stitching head, and a control panel, which work in tandem to provide a seamless operation.

The feeding system guides the bags into the machine, where the stitching head secures the edges. The control panel allows operators to adjust stitch length, speed, and the tension of the thread, ensuring that the stitching quality meets industry standards. Modern PP bag stitching machines can operate at speeds of up to 100 bags per minute, dramatically increasing productivity compared to manual stitching processes.

Advantages of Using PP Bag Stitching Machines

1. Increased Efficiency Automation reduces the time taken to stitch bags compared to manual methods. This efficiency translates into higher production rates and reduced labor costs.

2. Consistency and Quality Mechanical stitching ensures uniformity in stitch size and tension, which is difficult to achieve manually. This consistency enhances the bag's strength and reliability.

pp bag stitching machine

3. Versatility Many PP bag stitching machines are adaptable, capable of stitching different bag sizes and materials. This versatility allows manufacturers to cater to diverse market needs without investing in multiple machines.

4. Reduced Risk of Injury Manual stitching can lead to repetitive strain injuries and accidents. Mechanizing this process mitigates such risks, promoting a safer workplace.

5. Cost-Effectiveness While the initial investment in a stitching machine can be substantial, the long-term savings derived from increased productivity and reduced labor costs often justify the expense.

Innovations in PP Bag Stitching Technology

With the rise of Industry 4.0, PP bag stitching machines are also evolving through the integration of advanced technologies. For instance, many modern machines come equipped with sensors and monitoring systems that provide real-time feedback on stitching quality and machine performance. This data-driven approach allows for predictive maintenance, reducing downtime and ensuring smooth operations.

Moreover, the trend towards eco-friendly packaging solutions has led to the development of machines that can work with biodegradable threads and materials. This innovation aligns with the global push for sustainability, enabling companies to meet consumer demand for environmentally responsible products.

Conclusion

As the packaging industry continues to grow, the importance of efficient and reliable stitching solutions cannot be overstated. PP bag stitching machines represent a significant advancement in ensuring that products are securely packaged for distribution. Their ability to enhance efficiency, improve consistency, and reduce operational costs positions them as indispensable tools for manufacturers.

In summary, the evolution of PP bag stitching machines is a testament to the innovation and adaptability of the packaging industry. By leveraging modern technology and automation, manufacturers can not only meet the demands of today's fast-paced market but can also prepare for the challenges of tomorrow, ensuring that they remain competitive and responsive to consumer needs.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025