Sewing Machines for Jumbo Bag Production and Customization

Jumbo Bag Sewing Machinery Revolutionizing the Packaging Industry

In the modern era of manufacturing and packaging, efficiency and quality are of utmost importance. As businesses strive to optimize their operations and meet growing demands, specialized machinery such as jumbo bag sewing machines has emerged as a game changer. These machines are ingeniously designed for producing and sewing large bags made from various materials, commonly used in industries like agriculture, construction, and retail.

The Importance of Jumbo Bags

Jumbo bags, often referred to as FIBC (Flexible Intermediate Bulk Containers), are large capacity bags designed to hold a range of bulk materials. They are widely utilized across many sectors, including agriculture for grains, construction for minerals and sands, and even for packaging chemicals and food products. The efficiency of using jumbo bags over traditional packaging methods cannot be overstated. Their large volume reduces the need for excessive packaging, ultimately saving on materials and transportation costs.

Features of Jumbo Bag Sewing Machinery

The sewing machinery designed for jumbo bags is equipped with features that enhance productivity and ensure the robustness of the final product. These machines typically have heavy-duty capabilities to handle thick, multi-layered fabric that is often used in jumbo bags. Most models come with multiple sewing heads, enabling them to perform simultaneous sewing operations, which significantly accelerates the production process.

Additionally, many modern machines incorporate automated features such as computer numerical control (CNC) for precise stitching patterns, ensuring uniform performance and high-quality seams. Some machines also include safety features to prevent fabric damages, which can be costly in production delays and material waste.

Technological Advancements

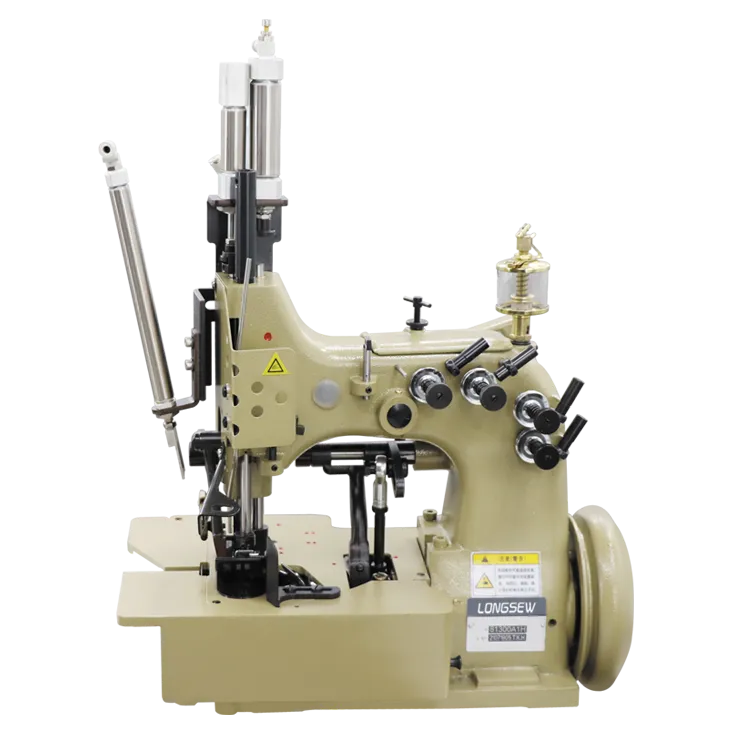

jumbo bag sewing machinery

The advancement of technology in sewing machinery has played a pivotal role in enhancing the efficiency of jumbo bag production. Today’s machines often come with integrated software that allows operators to program and customize sewing patterns, adjust tension settings, and monitor production metrics in real-time. This technology not only improves accuracy but also facilitates a seamless workflow, enabling manufacturers to produce high-quality bags at a faster rate.

Moreover, with the increasing focus on sustainability, many manufacturers are developing machines capable of handling eco-friendly materials. Biodegradable and recycled fabrics are becoming more popular, and the ability to sew these materials efficiently is crucial for environmentally-conscious businesses looking to reduce their carbon footprint.

Market Trends and Demand

As the global market continues to grow, so does the need for reliable packaging solutions. The demand for jumbo bags and the machinery that produces them is on the rise, particularly in emerging markets where industrial growth is booming. Companies are continually seeking ways to cut costs while maintaining the quality of their products. Investing in advanced sewing machinery is a strategic move that many manufacturers are considering to keep up with competition and meet their production goals.

The increase in e-commerce and online shopping has also fueled demand for durable packaging. With more products being shipped over longer distances, the robustness of jumbo bags provides an attractive solution for logistics companies looking to protect goods during transit.

Conclusion

Jumbo bag sewing machinery is an essential part of the modern manufacturing and packaging landscape. With its robust capabilities and technological advancements, it offers an efficient solution for producing sturdy bags that can hold a variety of bulk materials. As industries continue to evolve, the demand for these specialized machines is only expected to grow, making them a worthwhile investment for manufacturers looking to improve their production processes.

As we look to the future, the integration of innovative technologies, sustainability practices, and enhanced efficiency will likely shape the landscape of jumbo bag production. Businesses that embrace these advancements will not only thrive in the competitive market but will also pave the way for an environmentally-friendly approach to packaging. By continuing to refine the technology behind jumbo bag sewing machinery, the industry can ensure that it remains a vital component of the global supply chain for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025