jumbo bag auto sewing

The Evolution of Jumbo Bag Auto Sewing Revolutionizing Packaging Solutions

In the world of industrial packaging, the demand for efficiency, quality, and scalability has driven significant advancements in technology. One of the most notable innovations in this sector is the automatic sewing of jumbo bags. These large, durable bags are essential for transporting bulk materials across various industries, including agriculture, construction, mining, and food processing. The integration of automation in the sewing process not only enhances productivity but also ensures consistency and reliability in the final product.

Historically, the sewing of jumbo bags was a labor-intensive task, requiring skilled workers to manually sew the seams of these large bags. This process was not only time-consuming but also prone to human error, resulting in variations in seam quality and an increased risk of bag failure during handling or transit. With the growing demand for jumbo bags, especially in the global market, it became clear that there was a need for a more efficient solution.

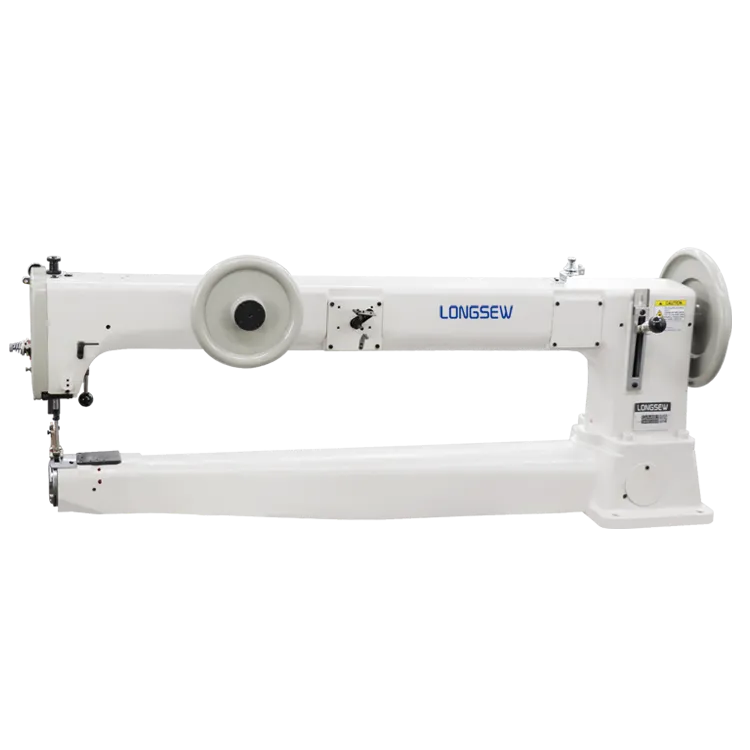

Enter the era of jumbo bag auto sewing. This innovative technology involves the use of automated sewing machines specifically designed to handle the size and material of jumbo bags, typically made from woven polypropylene or polyethylene. These machines can operate at high speeds, significantly reducing the time it takes to sew a single bag. Moreover, they are equipped with advanced features such as programmable settings, which allow for precise control over stitching patterns and seam integrity.

One of the primary benefits of jumbo bag auto sewing is the consistency it brings to the production process. Automated machines ensure that each bag is sewn to the same specifications, reducing the likelihood of defects. This consistency is crucial in industries where the integrity of the bag directly affects the safety and quality of the contents. For example, in food processing, a properly sewn bag not only secures the product but also prevents contamination, thereby adhering to strict safety regulations.

jumbo bag auto sewing

Moreover, the speed of automated sewing machines allows manufacturers to keep up with the increasing demand for jumbo bags. In a competitive marketplace, the ability to produce large quantities of bags quickly can be a significant advantage. This increased output not only meets customer needs more effectively but also helps companies reduce operational costs associated with labor and time.

In addition to improving efficiency and consistency, jumbo bag auto sewing machines are designed with user-friendly interfaces and advanced technology that help streamline the entire production process

. Operators can easily monitor the machines, troubleshoot issues, and perform maintenance, ensuring that production continues smoothly without significant downtime.Sustainability is another aspect that cannot be overlooked. Modern jumbo bag auto sewing machines often incorporate energy-efficient technologies and are designed to minimize material waste during the sewing process. As industries increasingly focus on reducing their environmental impact, this alignment with sustainable practices is an essential selling point.

As we look to the future, the potential for further advancements in jumbo bag auto sewing technology is immense. Innovations such as AI and machine learning could lead to even greater efficiencies, predictive maintenance, and enhanced quality control processes. The integration of smart technologies could revolutionize how manufacturers approach production, making it more agile and responsive to market demands.

In conclusion, jumbo bag auto sewing represents a significant milestone in the packaging industry. By enhancing efficiency, consistency, and sustainability, this technology not only meets the current needs of manufacturers but also sets the stage for future growth and innovation. As industries evolve, the automatic sewing of jumbo bags will undoubtedly continue to play a pivotal role in shaping the landscape of bulk material packaging.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025