Single Needle Industrial Sewing Machines for Efficient and Precise Stitching Solutions

The Single Needle Industrial Sewing Machine A Workhorse in Textile Production

The industrial sewing machine has long been the backbone of the textile and garment industry, with various models designed to meet specific needs. Among the most widely used models is the single needle industrial sewing machine. This machine, revered for its versatility and efficiency, plays a crucial role in the production of garments, upholstery, and other textile items.

What is a Single Needle Industrial Sewing Machine?

A single needle industrial sewing machine is designed to perform lockstitch sewing, using one needle and one bobbin to create a consistent and durable stitch. These machines are typically powered by an electric motor, allowing them to handle heavy materials and operate at high speeds, often reaching over 5,000 stitches per minute. This makes them ideal for environments where productivity and precision are paramount.

Versatility in Application

One of the key advantages of the single needle sewing machine is its versatility. It is suitable for a wide range of fabrics, from lightweight cotton to heavy denim and leather. This adaptability means that businesses can utilize the same machine for various projects without needing to invest in multiple specialized machines. Additionally, with the right attachments and presser feet, users can execute a variety of techniques, including straight stitching, zigzag stitching, and even decorative stitching.

Features of Single Needle Machines

Modern single needle industrial sewing machines come equipped with a plethora of features that enhance their functionality. Many include automatic needle positioning, which allows for easily aligning fabric corners and edges, resulting in cleaner and more professional-looking seams. Some models also feature programmable stitch patterns and adjustable stitch length, enabling workers to switch between different sewing styles with ease.

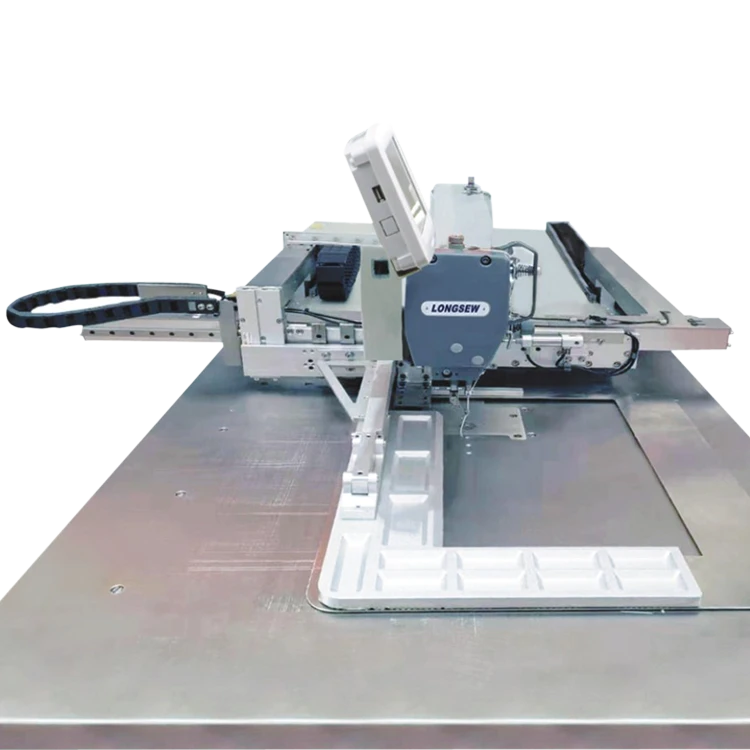

industrial sewing machine single needle

The feed mechanism is another critical feature; it can be either drop feed or walking foot, depending on the specific tasks the machine is most suited for. A walking foot feed system, for instance, is particularly beneficial when working with multiple layers of fabric, as it ensures even feeding and reduces the likelihood of puckering.

Maintenance and Longevity

Proper maintenance of a single needle industrial sewing machine is vital to ensure its longevity and performance. Regular cleaning to remove lint and debris, along with oiling the moving parts, can significantly extend the machine's lifespan. Furthermore, operators should be trained to troubleshoot common issues, such as tension adjustments and needle changes, to minimize downtime in a production environment.

Impact on Production Efficiency

In the fast-paced world of textile production, efficiency is key. The single needle industrial sewing machine has been designed with high throughput in mind, allowing companies to produce garments quickly without compromising on quality. This efficiency translates into shorter lead times and greater competitiveness in the marketplace.

Conclusion

As the textile industry continues to evolve, the single needle industrial sewing machine remains an essential tool for manufacturers worldwide. Its combination of speed, versatility, and durability make it the go-to choice for a myriad of sewing tasks. Whether in a bustling factory or a small workshop, these machines exemplify the technology that drives the industry forward, transforming fabrics into high-quality finished products that meet global demand. As businesses seek to optimize their production processes, the single needle industrial sewing machine undoubtedly stands out as a reliable and indispensable asset.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025