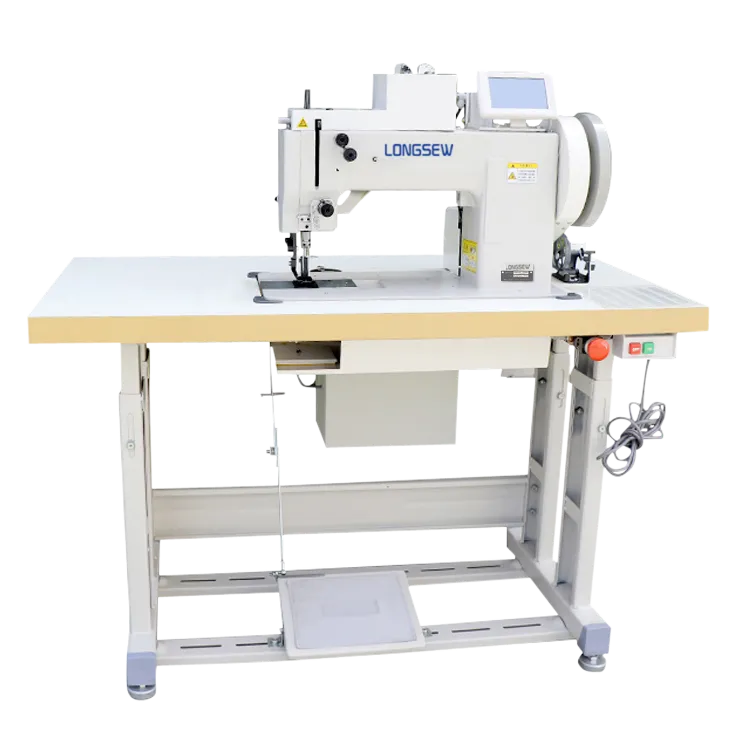

industrial sewing machine needles for leather

Understanding Industrial Sewing Machine Needles for Leather

When it comes to working with leather, the choice of the right tools is crucial for achieving a professional finish. One of the most important components in leather sewing is the sewing machine needle. Industrial sewing machine needles designed specifically for leather offer distinct benefits and performance characteristics that are essential for leatherwork.

Leather is a robust material that requires special attention during stitching. Regular sewing machine needles can struggle with the density and toughness of leather, resulting in skipped stitches, needle breakage, or material damage. This is where leather-specific needles shine. These needles are designed with a wedge-shaped point that allows them to penetrate the tough leather fibers without causing unnecessary damage. This design minimizes the risk of holes or tears and ensures a clean stitch.

Moreover, industrial sewing needles for leather come in various sizes and types to accommodate different leather weights and thicknesses. For instance, lighter leathers, such as lambskin, may require a smaller needle size, while heavier leathers, such as saddle or tooling leather, require larger, thicker needles to handle the weight without bending or breaking. Choosing the correct size needle is essential for ensuring smooth operations and achieving the desired outcome in leather projects.

industrial sewing machine needles for leather

Another critical factor to consider is the needle's material. Most industrial leather sewing needles are made from high-quality steel and undergo special treatments to enhance their strength and durability. Some may even come with a titanium coating, further increasing their lifespan and performance. The right material can make a significant difference, especially for industrial settings where needles undergo extensive use.

In addition to the needle type and material, sewing machine compatibility is also an important consideration. Not all needles fit all machines, so it’s crucial to ensure that the chosen needle matches the specific requirements of your industrial sewing machine. Many manufacturers provide charts and guidelines to help users select the right needle based on their machine model.

Lastly, taking care of your needles is vital. Regularly replacing dull or damaged needles will save you time and frustration. Routine maintenance checks and proper storage can also prolong the life of your needles and improve your overall sewing experience.

In conclusion, industrial sewing machine needles designed for leather play a pivotal role in achieving stellar results in leather craft. By understanding the characteristics and functions of these specialized needles, crafters and manufacturers alike can enhance their sewing practices, ensuring both precision and quality in their finished products. Whether you are creating leather garments, bags, or upholstery, investing in the right needles will undoubtedly make a notable difference in your crafting journey.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025