High-Performance Industrial Sewing Machine for Heavy-Duty Applications and Projects

The Importance of Industrial Heavy Duty Sewing Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. Among the tools that enable this efficiency is the industrial heavy duty sewing machine. These machines are integral to the textile industry, tackling the demanding requirements of fabric construction and offering solutions that standard machines cannot provide. With their robust design, advanced features, and versatile applications, industrial heavy duty sewing machines have become a crucial asset in various sectors.

Robust Construction and Longevity

One of the defining characteristics of industrial heavy duty sewing machines is their construction. Built to withstand the rigors of continuous use, these machines often feature a sturdy metal frame that minimizes vibration and ensures stability during operation. Unlike domestic sewing machines, which are meant for light to medium tasks, industrial sewing machines are engineered for heavy workloads, allowing them to sew through multiple layers of thick fabric, leather, and other tough materials without compromise. This durability not only extends the life of the machine but also reduces maintenance costs over time, making them a smart investment for businesses.

Speed and Efficiency

Time is money in manufacturing, and industrial heavy duty sewing machines are designed with speed in mind. These machines can operate at significantly faster speeds than their domestic counterparts, often exceeding 2000 stitches per minute. This increased speed leads to higher productivity, allowing manufacturers to meet tight deadlines without sacrificing quality. Additionally, features such as automatic threading, programmable stitch patterns, and built-in cutting mechanisms improve operational efficiency, further enhancing the output of production lines.

Advanced Technology and Versatility

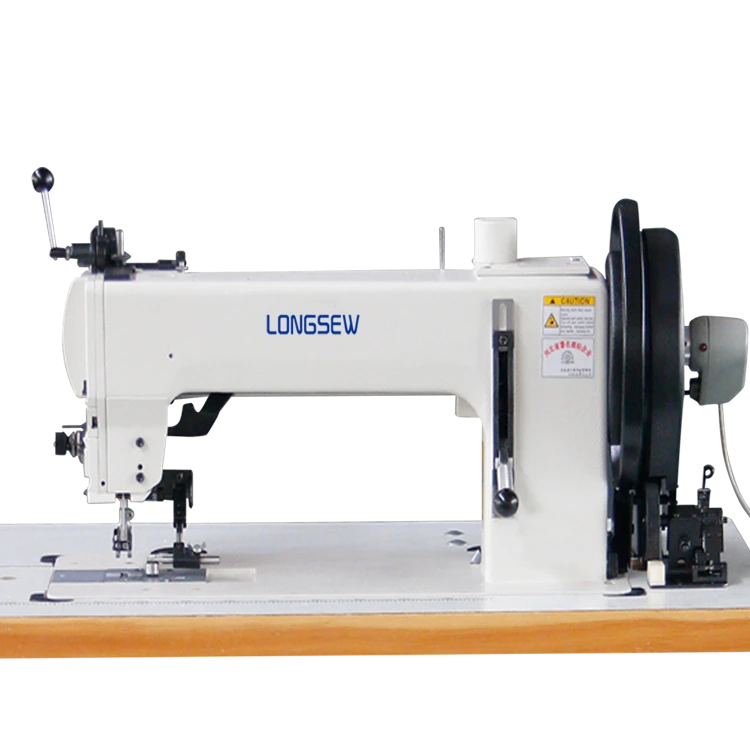

industrial heavy duty sewing machine

Modern industrial heavy duty sewing machines are equipped with advanced technology that expands their versatility. Many machines now offer computerized functions that allow for precise control over stitch length, width, and tension, tailoring each aspect to specific fabric types. This versatility is particularly important in industries such as fashion, automotive, and upholstery, where different materials require different handling. Whether it’s sewing zippers onto jackets, stitching upholstery for vehicles, or creating durable workwear, heavy duty sewing machines can adapt to a wide array of applications.

Moreover, some machines come with specialty attachments and accessories, enabling users to perform various sewing techniques such as double needle stitching, walking foot operations, and even embroidery. This adaptability not only streamlines production processes but also opens up creative possibilities for designers, allowing for innovative product development.

Cost-Effectiveness

Investing in industrial heavy duty sewing machines can initially seem daunting due to their higher price point compared to domestic machines. However, their ability to handle heavy-duty tasks and run for extended periods makes them a cost-effective solution in the long run. Businesses experience reduced labor costs as a result of the machines’ efficiency and speed, which can lead to quicker turnaround times and happier clients. Furthermore, the longevity of these machines means that while the upfront investment may be significant, it is offset by their extended lifespan and minimal need for repairs.

Conclusion

Industrial heavy duty sewing machines are essential in modern manufacturing, providing robust solutions for a variety of industries. Their durability, speed, and versatility make them indispensable tools for businesses looking to enhance productivity, manage costs, and produce high-quality products. As the textile industry continues to evolve, the role of these advanced machines will only grow, reinforcing their importance as pillars of efficient and effective production processes. By investing in the right equipment, manufacturers can not only meet the demands of today but also seize opportunities for innovation and growth in the ever-competitive market. The industrial heavy duty sewing machine is not just a tool; it represents a commitment to quality and excellence in the world of textiles.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025