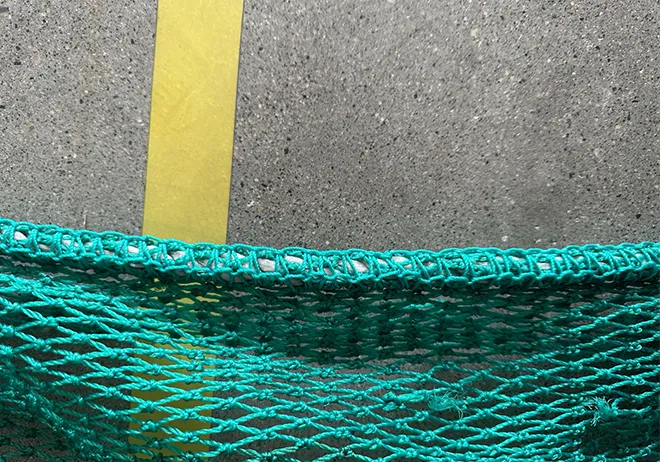

heavy duty lock stitch

The Heavy Duty Lock Stitch A Key Component in Industrial Sewing

When it comes to sewing, especially in industrial contexts, the choice of stitch plays a crucial role in the durability and functionality of the finished product. One of the most reliable and widely used types of stitches in industrial sewing is the heavy-duty lock stitch. This article delves into the characteristics, applications, and advantages of heavy-duty lock stitches, highlighting their importance to various sectors.

What is a Lock Stitch?

A lock stitch is a type of stitch that utilizes two threads the needle thread and the bobbin thread. The needle thread, usually made of polyester or nylon for heavy-duty applications, passes through the fabric and forms a loop that is secured by the bobbin thread from below. This interlocking of threads creates a secure and tight seam, essential for maintaining the integrity of the fabric layers. The heavy-duty lock stitch is specifically designed to endure high stress and heavy usage, making it an ideal choice for various industrial applications.

Characteristics of Heavy Duty Lock Stitches

1. Strength and Durability Heavy-duty lock stitches are renowned for their strength. The interlocking mechanism ensures that the stitch can handle significant tension and pressure without compromising the seam integrity. This characteristic makes them suitable for heavy materials such as denim, canvas, and leather.

2. Consistent Tension Lock stitches provide consistent tension along the seam, which is crucial for maintaining the fabric’s structure. This consistency prevents puckering and distortion, contributing to a professional finish in industrial applications.

3. Versatility Heavy-duty lock stitches can be used on a wide range of fabrics and thicknesses. Whether sewing upholstery, automotive interiors, or bags and luggage, the versatility of heavy-duty lock stitches serves various industries.

4. Resistance to Fraying The locked nature of the stitch helps prevent unraveling and fraying of the fabric edges. This feature is particularly advantageous in high-stress environments where wear and tear are expected.

5. Ease of Maintenance Lock stitches tend to be easier to work with in terms of machine maintenance. Unlike other stitch types that may require more intricate adjustments, heavy-duty lock stitches can often be sewn with standard industrial sewing machines with minimal adjustments.

Applications of Heavy Duty Lock Stitches

Heavy-duty lock stitches are employed in a myriad of industries where robust and durable seams are critical. Some notable applications include

heavy duty lock stitch

- Apparel Manufacturing In the production of workwear, outdoor clothing, and fashion pieces made of tougher materials, heavy-duty lock stitches ensure that garments withstand everyday wear and tear. - Upholstery In the furniture industry, these stitches provide strength to seams on items such as sofas and chairs, where heavy use is expected.

- Automotive Textiles Car interiors often require strong stitching to hold components like seats and carpets together. Heavy-duty lock stitches ensure that these vital elements remain intact over time.

- Outdoor Equipment Products like tents, backpacks, and other gear designed for outdoor activities benefit from the durability of heavy-duty lock stitches, which can resist the rigors of the elements

.- Leather Goods From belts to handbags, heavy-duty lock stitches are essential in creating robust seams that enhance both the aesthetics and durability of leather products.

Advantages of Using Heavy Duty Lock Stitches

The use of heavy-duty lock stitches comes with numerous advantages

1. Enhanced Product Life The durability of the stitch contributes to the overall longevity of products, making it a cost-effective choice for manufacturers.

2. Improved Aesthetics A uniform and high-quality finish is often achieved with lock stitches, which appeal to consumers seeking premium products.

3. Efficiency Sewing with heavy-duty lock stitches can be faster than other stitching methods, increasing production efficiency for manufacturers.

4. Reduced Risk of Seams Opening The secure nature of the stitch minimizes the risk of seams opening, ensuring products remain functional and safe to use.

In conclusion, the heavy-duty lock stitch is an essential element in industrial sewing that offers unmatched strength, durability, and versatility. Its wide range of applications, combined with its numerous advantages, makes it the preferred choice for many manufacturers looking to produce high-quality, long-lasting products. Whether in the fashion industry, automotive manufacturing, or outdoor equipment production, heavy-duty lock stitches are indispensable for ensuring that seams withstand the rigors of their intended use.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025