Innovative Sewing Machine Heads for FIBC Production and Efficiency Enhancement

Understanding FIBC Sewing Machine Heads An Essential Element in Bulk Packaging

In the world of packaging, particularly for bulk materials, FIBC (Flexible Intermediate Bulk Container) bags have become a pivotal solution. These versatile bags are used extensively across various industries, including agriculture, food processing, chemicals, and many others. The efficiency and durability of FIBC bags largely depend on the quality of their construction, and at the heart of this construction is the sewing machine head. This article explores the significance of FIBC sewing machine heads, including their types, functionalities, and impact on product quality.

What is an FIBC Sewing Machine Head?

An FIBC sewing machine head is a specialized component designed to stitch together the various sections of an FIBC bag. These sewing machines are distinct due to their ability to handle thick, heavy-duty fabrics, which are often made from polypropylene or other robust materials. The sewing machine head utilizes high-tensioned threads to ensure that the seams are strong enough to withstand the stresses associated with bulk material handling.

Types of FIBC Sewing Machine Heads

There are several types of sewing machine heads used in the production of FIBC bags

1. Lockstitch Machine This type is the most common for sewing FIBC bags, providing a tight and secure stitch. It creates a perfect loop with two threads, making it suitable for heavy-duty applications.

2. Overlock Machine While not as commonly used as lockstitch machines, overlock machines can also be employed in FIBC bag production. They are primarily utilized for finishing edges and preventing fraying, contributing to the overall durability of the bag.

3. Walking Foot Machine This machine is particularly useful for sewing multiple layers of fabric, as it moves the fabric through the machine while maintaining an even stitch length. It is ideal for crafting seams that require precision and strength.

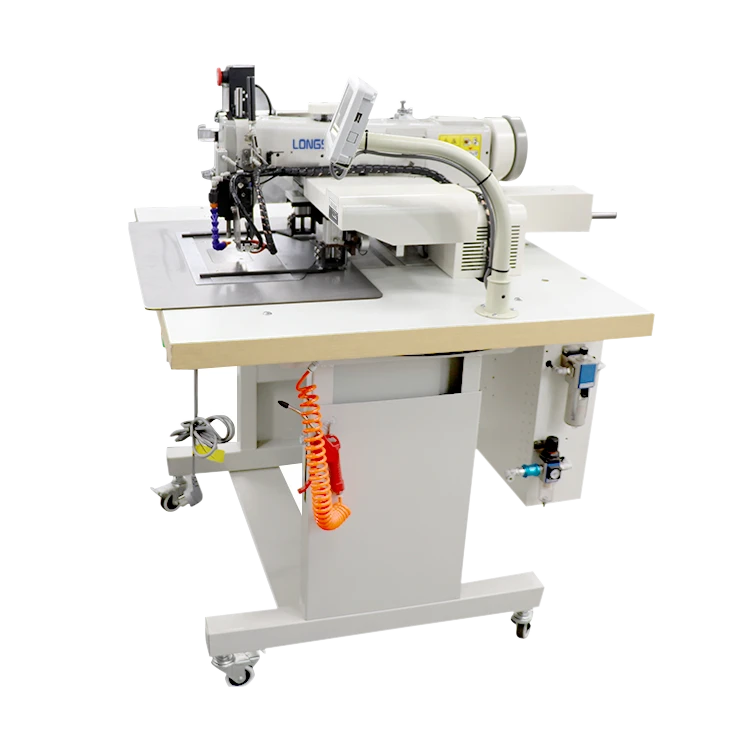

fibc sewing machine head

Key Features and Benefits

FIBC sewing machine heads come with various features that enhance their functionality

- Heavy-duty Construction These machines are designed to handle the thick materials used in FIBC bags, ensuring durability and reliability. - High Speed Modern sewing machines operate at high speeds, enabling manufacturers to produce bags efficiently and meet large order demands without compromising quality.

- Adjustable Tension Control Many FIBC sewing machines come with adjustable tension control, allowing operators to customize the thread tension for different types of fabrics, ensuring optimal seam integrity.

- User-Friendly Interfaces Advanced sewing machines are equipped with intuitive controls, making it easier for operators, regardless of skill level, to produce high-quality FIBC bags.

Impact on Product Quality

The sewing machine head plays a crucial role in determining the overall quality and performance of FIBC bags. A well-stitched seam prevents leaks and reduces material waste, which is essential in industries where product integrity is paramount. High-quality sewing machine heads contribute to the longevity of the bags, ensuring they can withstand the rigors of transportation and storage.

In conclusion, the FIBC sewing machine head is an indispensable component in the production of flexible bulk containers. Its ability to create robust, reliable seams ensures that manufacturers can consistently deliver high-quality packaging solutions to their clients. As industries continue to evolve, the demand for efficient, durable, and cost-effective packaging like FIBC bags will remain essential, highlighting the importance of investing in advanced sewing technologies.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025