Industrial Double Needle Sewing Machine for Professional Garment Production and Quality Stitching

Exploring the Double Needle Sewing Machine in Industrial Applications

The double needle sewing machine is a pivotal tool in the textile industry, known for its efficiency, precision, and versatility. It is prominently used in manufacturing garments and other textile products, where a double stitching technique is essential for durability and aesthetic appeal. This article delves into the features, advantages, and applications of double needle sewing machines in industrial settings.

What is a Double Needle Sewing Machine?

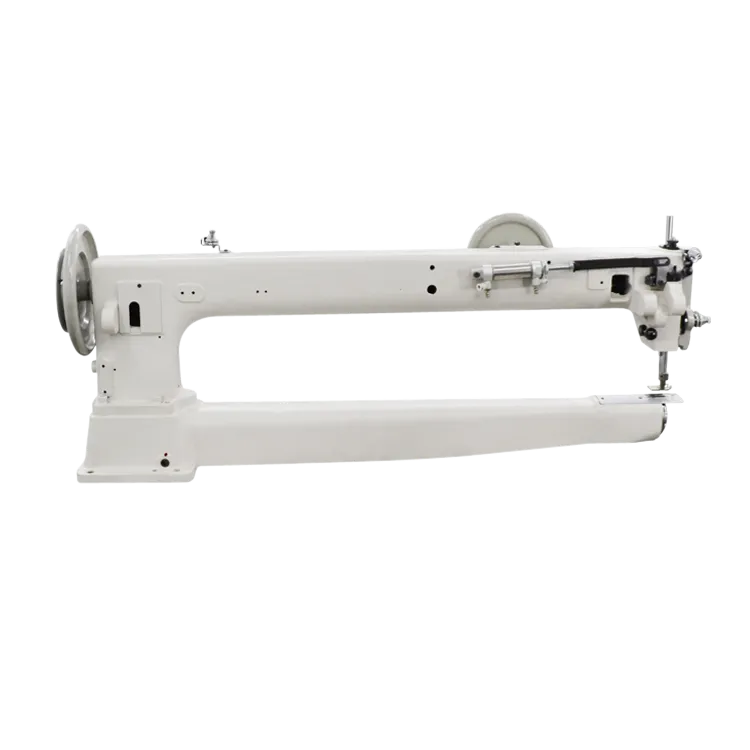

A double needle sewing machine is equipped with two needles that operate simultaneously to create two parallel rows of stitches. This mechanism allows for the production of complex stitch patterns which enhance both the functionality and style of sewn products. Ideally constructed to accommodate various fabric thicknesses, these machines generally employ a flatbed or cylinder bed design which provides ease in maneuvering fabric.

Key Features

The design of double needle sewing machines includes multiple features aimed at improving productivity

1. Two Needle Configuration This fundamental feature allows for double stitching, which not only boosts the strength of seams but also provides a professional finish.

2. Tension Controls Many models come equipped with adjustable tension controls enabling users to tailor settings according to fabric type, ensuring even stitches.

3. Walking Foot Mechanism This mechanism helps in feeding multiple layers of fabric uniformly, essential for quilting and sewing thicker materials.

4. Speed Industrial double needle sewing machines are engineered for high-speed sewing, with some machines capable of stitching up to 5,000 stitches per minute, significantly reducing production time.

5. Versatility These machines can handle various materials, from delicate fabrics like silk to heavy-duty materials like canvas, making them suitable for diverse applications in the garment industry.

Advantages of Using Double Needle Sewing Machines

The adoption of double needle sewing machines brings numerous advantages to industrial sewing operations

double needle sewing machine industrial

1. Increased Efficiency With the capability of performing two sewing tasks simultaneously, these machines significantly reduce the number of operations needed for complex seams, enhancing overall efficiency.

2. Enhanced Durability Double stitches are inherently stronger than single stitches, which translates to more durable seams. This durability is crucial for items such as jeans, outerwear, and sports apparel that undergo constant stress.

3. Aesthetic Appeal The parallel stitching lines produced by double needle machines not only reinforce the fabric but also add a visually appealing element to the finished product, making them popular in fashion and apparel design.

4. Cost-Effectiveness Although the initial investment for a double needle machine may be higher, the long-term savings in terms of time and reduced labor costs make it a cost-effective solution for many manufacturers.

5. Quality Control Consistency is key in industrial production; double needle machines provide uniform stitch quality, which contributes to the overall quality control of the products.

Applications in the Textile Industry

The versatility of double needle sewing machines allows them to be utilized in various sectors of the textile industry

1. Apparel Manufacturing They are extensively used for stitching seams on garments such as shirts, blouses, pants, and jackets, ensuring both durability and style.

2. Home Textiles Industries producing curtains, bed linens, and upholstery benefit from the double needle technique for added strength and decorative stitching.

3. Leather Goods Heavy-duty double needle machines are essential for leather crafting, providing the strength required for seams in bags, belts, and other leather accessories.

4. Sportswear In the manufacture of sportswear, double needle machines ensure that seams can withstand stress from movement and activity without compromising integrity.

Conclusion

In conclusion, the double needle sewing machine is an invaluable asset in the industrial sewing landscape. Its capabilities enhance not just production efficiency but also product quality. As industries continue to evolve, the reliance on such advanced sewing technology will undoubtedly grow, paving the way for innovative designs and superior textiles. Understanding and leveraging the advantages of double needle sewing machines can significantly bolster a manufacturer’s competitiveness in the ever-demanding market. With the right tools at hand, the future of textile production looks promising.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025