cylindrical sewing machine

The Evolution and Impact of the Cylindrical Sewing Machine

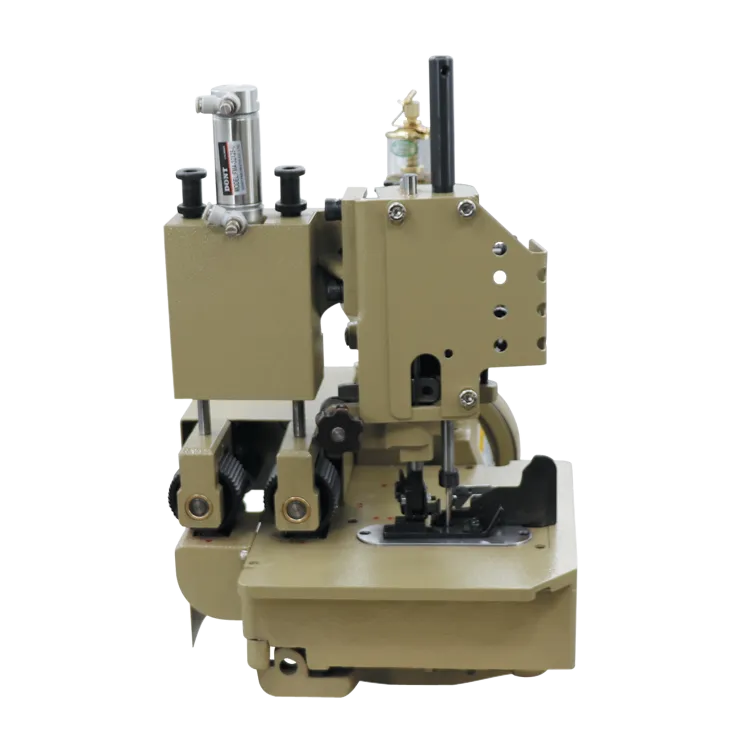

The cylindrical sewing machine has become an indispensable tool in the garment and textile industry, particularly due to its unique design and functionality that cater specifically to sewing tubular fabrics. This specialized machine has not only streamlined production processes but also enhanced the quality of sewn products, playing a crucial role in the evolution of apparel manufacturing.

Historical Background

The origins of sewing machines date back to the 18th century, with various inventors seeking ways to mechanize the process of stitching. However, it wasn't until the 19th century that more specialized machines emerged. The cylindrical sewing machine, specifically designed for tubular and round items, was developed to meet the demands of an evolving garment industry that sought efficiency and precision. The innovation allowed manufacturers to produce garments like t-shirts, sleeves, and cuffs with greater speed and accuracy compared to traditional flatbed machines.

Design and Functionality

What sets the cylindrical sewing machine apart is its unique cylindrical bed, which enables the operator to easily manipulate tubular fabrics. This design feature allows for better access to the inner seams of garments, making it ideal for sewing pieces that would be difficult to manage with flatbed machines. The machine typically comprises several components a sewing head, a needle, a bobbin, and various feeding mechanisms. The cylindrical bed allows continuous feeding of fabric, which is particularly advantageous during high-volume production runs.

The functionality of these machines has evolved significantly. Advanced models now incorporate computerized technology that offers features such as programmable stitching patterns, automatic thread trimming, and adjustable sewing speed, enhancing both user experience and productivity. This technological evolution has made cylindrical sewing machines more accessible, allowing small and medium-sized enterprises to utilize them effectively.

Advantages in Production

The cylindrical sewing machine brings several advantages to the production floor. First, it significantly increases production efficiency. The ability to sew tubular fabrics without requiring extensive manipulation reduces labor time, thus increasing output. Furthermore, the consistency and precision offered by these machines ensure a higher quality of stitching, which is essential in maintaining garment standards.

cylindrical sewing machine

Another benefit is versatility. Although primarily designed for tubular fabrics, modern cylindrical machines can also handle various materials, including knits, wovens, and technical textiles, making them suitable for diverse applications, from fashion clothing to functional workwear.

Challenges and Considerations

Despite their many advantages, cylindrical sewing machines are not without challenges. Proper training is essential for operators to maximize the machine's capabilities. An inexperienced user may struggle with thread tension and fabric handling, leading to defects in stitching. Furthermore, maintenance is crucial; these machines require regular servicing to ensure optimal performance and longevity.

The initial investment is another point of consideration. While cylindrical machines can dramatically enhance productivity, the upfront cost may be a barrier for smaller manufacturers. However, when viewed through the lens of return on investment, the increased efficiency often justifies the expense.

Future Trends

As the garment industry evolves, so too will the cylindrical sewing machine. Future development is likely to focus on automation and smart technology, integrating artificial intelligence and IoT solutions to further streamline production processes. These advancements could lead to even higher accuracy in stitching and reduced waste, aligning with the industry’s growing emphasis on sustainability.

Additionally, as the demand for customized and small-batch production increases, cylindrical sewing machines will likely adapt to facilitate rapid prototyping and faster turnaround times, making them even more valuable in modern apparel manufacturing.

Conclusion

The cylindrical sewing machine has undeniably transformed the textile and garment industry. From its historical significance to its modern-day applications, this machine exemplifies innovation tailored specifically for the needs of garment manufacturers. As technology continues to advance, the cylindrical sewing machine will undoubtedly evolve, keeping pace with the ever-changing landscape of fashion production while maintaining its critical role in ensuring quality and efficiency in garment construction.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025