Optimizing CNC Machine Operations for Enhanced Precision and Efficiency in Manufacturing

The Evolution and Impact of CNC Machines in Modern Manufacturing

Computer Numerical Control (CNC) machines have revolutionized the landscape of manufacturing since their inception in the mid-20th century. Given their precise and efficient capabilities, CNC machines have become an integral part of various industries, including aerospace, automotive, electronics, and even furniture production. This article delves into the significance of CNC machines, their operational principles, and the future of manufacturing in light of this cutting-edge technology.

The Basics of CNC Technology

CNC machines operate based on a programming language known as G-code, which communicates with the machine to perform a series of controlled movements. This allows the machine to accurately cut, shape, and assemble materials with minimal human intervention. The primary components of a CNC machine include the computer interface, drive motors, the control system, and the machine tool itself, which may be a mill, lathe, or router.

The transition from manual machining to CNC machining brings several advantages. Firstly, precision is unparalleled; CNC machines consistently produce parts within tight tolerances. Secondly, the automation of repetitive tasks reduces the risk of human error, leading to higher quality products. Furthermore, CNC machines can work continuously, enhancing productivity and enabling manufacturers to meet increasing demand without compromising quality.

Applications Across Industries

CNC technology has found applications across a multitude of sectors. In the aerospace industry, for example, CNC machines are used to create complex components such as turbine blades and aircraft fuselages, which require high precision and are subject to strict safety standards. Similarly, in the automotive industry, CNC machining facilitates the production of intricate parts such as engine blocks and transmission housings, which are essential for vehicle performance.

In addition to heavy industries, CNC technology has also made its mark in the arts and crafts sector. Artists and designers use CNC machines to carve, engrave, and fabricate bespoke items with unmatched detail and consistency. From intricate jewelry designs to custom furniture pieces, the possibilities are virtually limitless.

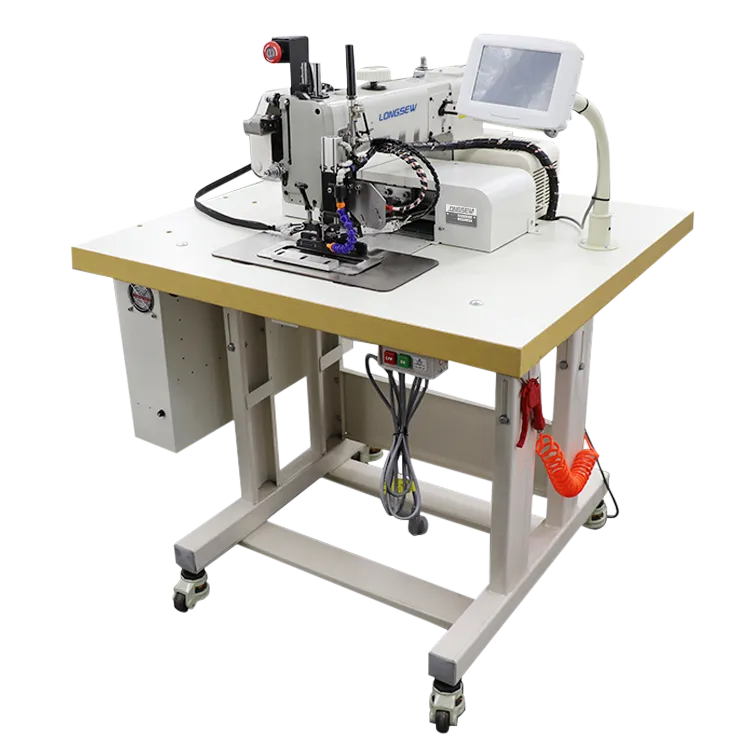

cnc machine silai

The Future of CNC Machines

With technological advancements, the future of CNC machines appears even more promising. One notable trend is the integration of artificial intelligence (AI) and machine learning. These technologies can analyze data collected from CNC operations to optimize production processes, predict maintenance needs, and improve overall efficiency.

Another exciting development is the advent of additive manufacturing combined with CNC machining, commonly referred to as hybrid manufacturing. This approach allows manufacturers to create complex geometries that would be otherwise impossible with traditional machining alone. By layering materials through additive processes and then refining them with CNC techniques, hybrid manufacturing opens new doors for innovation in product design and fabrication.

Challenges and Considerations

Despite their numerous advantages, the implementation of CNC machines is not without challenges. Initial investment costs can be high, and companies must also invest in training their workforce to operate these sophisticated machines. Moreover, the rapid evolution of technology means that businesses must stay informed about the latest advancements to remain competitive.

Sustainability is also a vital consideration in the development of CNC technology. As industries strive to reduce their environmental footprint, manufacturers are increasingly focusing on creating energy-efficient CNC machines and minimizing waste in their production processes.

Conclusion

CNC machines have undeniably transformed the manufacturing sector, bringing unprecedented levels of accuracy, efficiency, and flexibility. As technology continues to advance, the capabilities of CNC machines will further expand, paving the way for innovative applications across various industries. While challenges remain, the benefits far outweigh the downsides, positioning CNC technology as a cornerstone of modern manufacturing practices. The future promises exciting developments that will continue to shape how we design, produce, and consume products, ultimately leading to a more efficient and sustainable manufacturing landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025