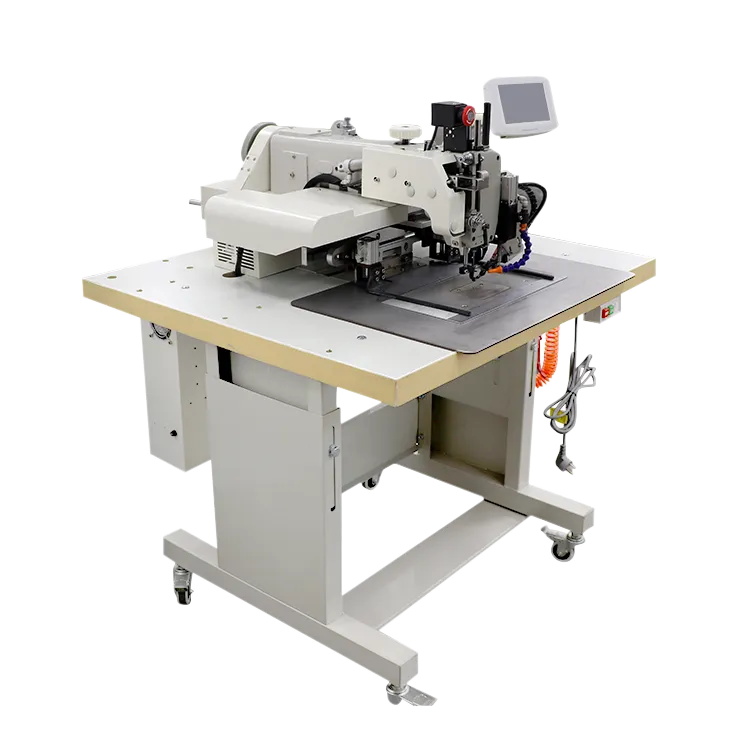

car seat sewing machine

The Importance of Sewing Machines in Car Seat Manufacturing

In the world of automotive production, car seat manufacturing plays a crucial role in ensuring comfort, safety, and aesthetics within vehicles. At the heart of this process lies a vital tool the sewing machine. As technology evolves, the type and capabilities of sewing machines have drastically improved, making them indispensable in the car seat manufacturing industry.

Evolution of Sewing Machines in Automotive Industry

Traditionally, sewing machines utilized in car seat production were basic and limited in functionality. However, with advancements in technology, modern sewing machines are equipped with features tailored to meet the demands of car upholstery. These machines possess high-speed sewing capabilities, automated stitch patterns, and specialized attachments designed for heavy-duty fabrics, enabling manufacturers to produce high-quality car seats efficiently.

Enhanced Fabric Handling

Car seats are often made from a variety of materials, including leather, vinyl, and durable fabric blends. Each of these materials has unique stitching requirements, and modern sewing machines are designed to handle such diverse fabrics with ease. Advanced feed mechanisms ensure that materials are moved uniformly through the machine, preventing issues like fabric slippage or uneven stitching—two common problems in traditional sewing setups. Consequently, the integration of sophisticated sewing machines leads to a better-finished product, enhancing the overall appeal of the car’s interior.

Automation and Precision

car seat sewing machine

Automation in sewing technology has transformed the way car seats are produced. With computer-controlled sewing machines, manufacturers can achieve a level of precision that manual sewing simply cannot match. These machines can replicate intricate designs and customized patterns consistently, which is essential for brands aiming to provide personalized interiors for their vehicles. Furthermore, automated sewing solutions reduce human error, ensuring that each stitch is performed perfectly and enhancing the durability of the car seats.

Sustainability Considerations

As the automotive industry shifts towards sustainability, sewing machines are also evolving to meet this challenge. Modern machines utilize energy-efficient technologies and can work with eco-friendly materials. Manufacturers are increasingly opting for sustainable fabrics and eco-conscious production methods. This shift not only minimizes environmental impact but also aligns with consumers' growing demand for greener products. Sewing machines that can handle these materials help facilitate this important transition in the industry.

Workforce Skills and Training

Despite the advanced capabilities of modern sewing machines, the human element remains essential in car seat manufacturing. Skilled workers are needed to operate these machines effectively and to understand the complexities of different materials and designs. Therefore, training programs that focus on both machine operation and textile knowledge are crucial. Investing in workforce skills ensures that manufacturers not only produce high-quality products but also maintain a knowledgeable workforce adaptable to future advancements.

Conclusion

In conclusion, sewing machines have become a cornerstone of car seat manufacturing by enhancing efficiency, precision, and adaptability in production processes. The integration of advanced technology in sewing machines continues to revolutionize the way car seats are made, contributing to improved product quality and sustainability in the automotive industry. As manufacturers increasingly embrace automation and sustainable practices, the role of sewing machines will undoubtedly expand, solidifying their place as essential tools in the automotive upholstery sector. The future of car seat manufacturing is bright, and sewing machines will remain at the forefront of this evolution.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025