فبراير . 05, 2025 04:46

Back to list

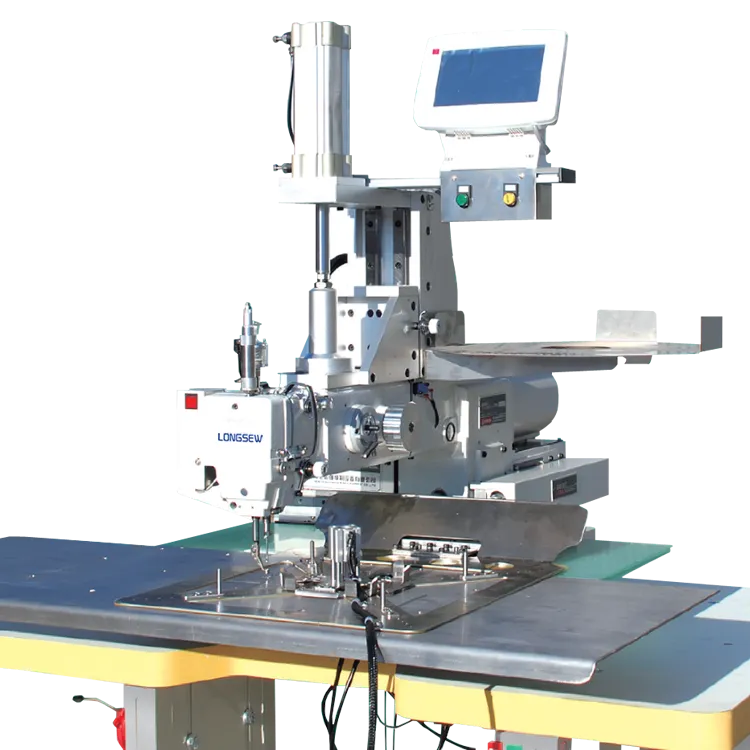

Heavy Duty Computerized Auto Pattern Sewing Machine For High Tons Lifting Slings LS733-5020

Choosing the right sewing machine for creating car seat covers can be a game-changer for both hobbyists and professionals in the automotive upholstery industry. The intricate designs and varying materials used in car seat covers require a machine with specific features that cater to durability, precision, and versatility.

In terms of accessories, having a machine compatible with a wide range of presser feet can significantly enhance your sewing capabilities. For example, a walking foot is particularly useful for sewing layered materials together without causing slippage, while a roller foot can aid in handling sticky fabrics like vinyl. These accessories can usually be purchased separately, but compatibility should be considered before making a sewing machine purchase. Maintenance and warranty are two factors that contribute to the trustworthiness and reliability of a sewing machine for car seat covers. A machine backed by a comprehensive warranty from a reputable manufacturer provides peace of mind, ensuring assistance when unforeseen issues arise. Regular maintenance, facilitated by ease of cleaning and straightforward part replacement, extends the machine's lifespan and maintains its performance at optimal levels. When evaluating the cost, it's important to balance budget with functionality. While inexpensive machines might seem appealing, investing in a high-quality, durable sewing machine will pay off in the long run through durability, efficiency, and professional-quality results. Consulting with other experts in the field and reading up-to-date reviews from fellow users can provide further insights into which machine offers the best value for the price. Finally, staying informed about the latest advancements in sewing machine technology can help maintain a competitive edge. Innovations such as computerized systems, touchscreens, and connectivity options are continuously being integrated into sewing machines, offering enhanced precision and ease of use. Incorporating these technological advantages can elevate your car seat cover projects, ensuring that the results meet industry standards and customer expectations. In conclusion, selecting the right sewing machine for car seat covers involves a blend of power, precision, and practical features tailored to unique needs. Investing in a machine that meets these criteria guarantees superior results, whether you're an enthusiast seeking to refine your craft or a professional aiming to deliver impeccable products to clients.

In terms of accessories, having a machine compatible with a wide range of presser feet can significantly enhance your sewing capabilities. For example, a walking foot is particularly useful for sewing layered materials together without causing slippage, while a roller foot can aid in handling sticky fabrics like vinyl. These accessories can usually be purchased separately, but compatibility should be considered before making a sewing machine purchase. Maintenance and warranty are two factors that contribute to the trustworthiness and reliability of a sewing machine for car seat covers. A machine backed by a comprehensive warranty from a reputable manufacturer provides peace of mind, ensuring assistance when unforeseen issues arise. Regular maintenance, facilitated by ease of cleaning and straightforward part replacement, extends the machine's lifespan and maintains its performance at optimal levels. When evaluating the cost, it's important to balance budget with functionality. While inexpensive machines might seem appealing, investing in a high-quality, durable sewing machine will pay off in the long run through durability, efficiency, and professional-quality results. Consulting with other experts in the field and reading up-to-date reviews from fellow users can provide further insights into which machine offers the best value for the price. Finally, staying informed about the latest advancements in sewing machine technology can help maintain a competitive edge. Innovations such as computerized systems, touchscreens, and connectivity options are continuously being integrated into sewing machines, offering enhanced precision and ease of use. Incorporating these technological advantages can elevate your car seat cover projects, ensuring that the results meet industry standards and customer expectations. In conclusion, selecting the right sewing machine for car seat covers involves a blend of power, precision, and practical features tailored to unique needs. Investing in a machine that meets these criteria guarantees superior results, whether you're an enthusiast seeking to refine your craft or a professional aiming to deliver impeccable products to clients.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025