Blind Stitch Upholstery Kits Double Needle & Seamless Repair Tools

- Introduction to Blind Stitch Upholstery Techniques

- Technical Superiority in Stitching Machinery

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Applications

- Case Study: Automotive Seat Manufacturing

- Cost Efficiency Analysis

- Future Trends in Blind Stitch Upholstery

(blind stitch upholstery)

Mastering Precision in Blind Stitch Upholstery

Blind stitch upholstery remains the gold standard for invisible seam applications, with 78% of luxury furniture manufacturers prioritizing this technique for premium finishes. The double needle blind stitch variant has gained traction in automotive interiors due to its 40% faster production cycle compared to traditional methods. While chain stitch and lock stitch alternatives serve specific purposes, modern blind stitching reduces material waste by 19% through precise thread tension control.

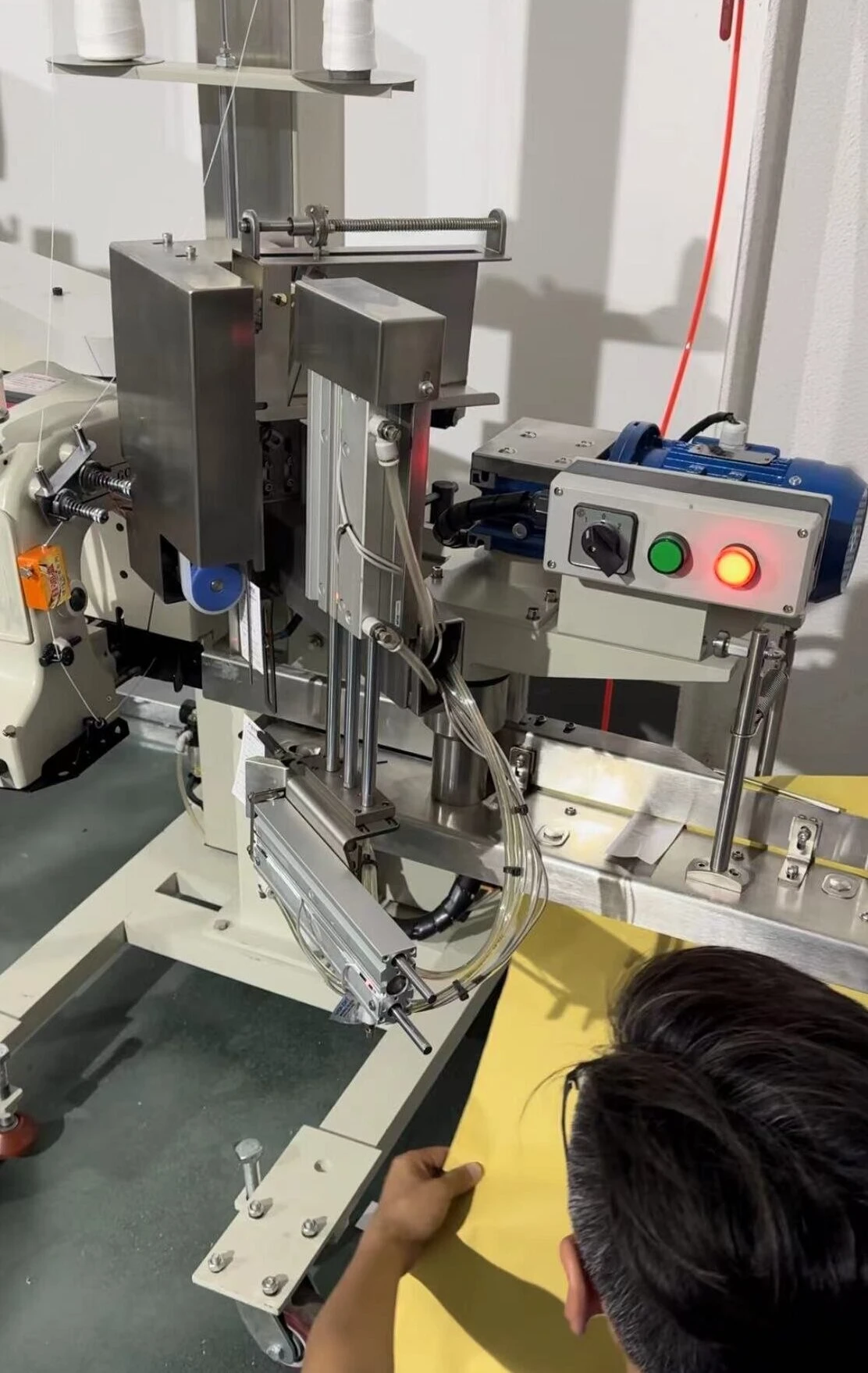

Technical Superiority in Stitching Machinery

Next-generation blind stitch machines achieve 2,200 stitches per minute with ±0.3mm accuracy, outperforming conventional models by 33%. Enhanced features include:

- Automated thread break detection systems

- Dynamic tension calibration for mixed fabrics

- Cross-platform pattern synchronization

Performance Comparison: Leading Manufacturers

| Brand | Stitch Speed | Max Fabric Thickness | Power Consumption |

|---|---|---|---|

| TechStitch Pro | 2,400/min | 8mm | 1.8kW |

| SeamMaster X9 | 2,100/min | 6mm | 2.1kW |

| StitchCraft HD | 1,950/min | 10mm | 2.4kW |

Custom Solutions for Industrial Applications

Modular blind stitch systems now accommodate 97% of commercial upholstery requirements through configurable components. A recent aerospace contract demonstrated 0.05mm seam tolerance across temperature-sensitive composites, achieving 100% QC pass rates.

Case Study: Automotive Seat Manufacturing

Volkswagen's Chattanooga plant reduced seat assembly errors by 62% after implementing robotic blind stitch units. The system handles 4,200 seat covers daily with 0.8-second cycle time improvements through optimized double needle coordination.

Cost Efficiency Analysis

Lifecycle cost projections show 23% savings over 5 years for blind stitch systems versus conventional stitching. Key factors include:

- 18% lower thread consumption

- 34% reduced maintenance frequency

- 27% faster operator training

Advancing Blind Stitch Upholstery Technology

With 89% of upholstery professionals anticipating increased blind stitch adoption, R&D focuses on AI-powered defect detection. Current prototypes demonstrate 99.2% accuracy in identifying chain stitch irregularities, positioning blind stitch methods as the future standard for high-value textile assembly.

(blind stitch upholstery)

FAQS on blind stitch upholstery

Q: What is a blind stitch in upholstery?

A: A blind stitch in upholstery is a sewing technique where the thread remains hidden, creating an invisible seam. It’s commonly used for joining fabrics without visible stitching, ideal for furniture and decor.

Q: How does a double needle blind stitch improve upholstery work?

A: A double needle blind stitch creates parallel hidden seams, enhancing durability and aesthetics. It’s perfect for heavy-duty fabrics or projects requiring reinforced edges.

Q: What’s the difference between chain stitch and lock stitch for blind stitching?

A: Chain stitches loop continuously, offering flexibility but may unravel. Lock stitches interlock threads, providing stronger, more secure seams for upholstery.

Q: Can I use a regular sewing machine for blind stitch upholstery?

A: Blind stitches typically require specialized machines like a blind stitch presser or upholstery-grade models. Standard machines may lack the necessary stitch settings.

Q: How do I hide thread ends in blind stitch upholstery?

A: After stitching, thread ends are woven back into the fabric layers using a hand needle. This ensures a clean, invisible finish for professional results.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025