يناير . 09, 2025 14:04

Back to list

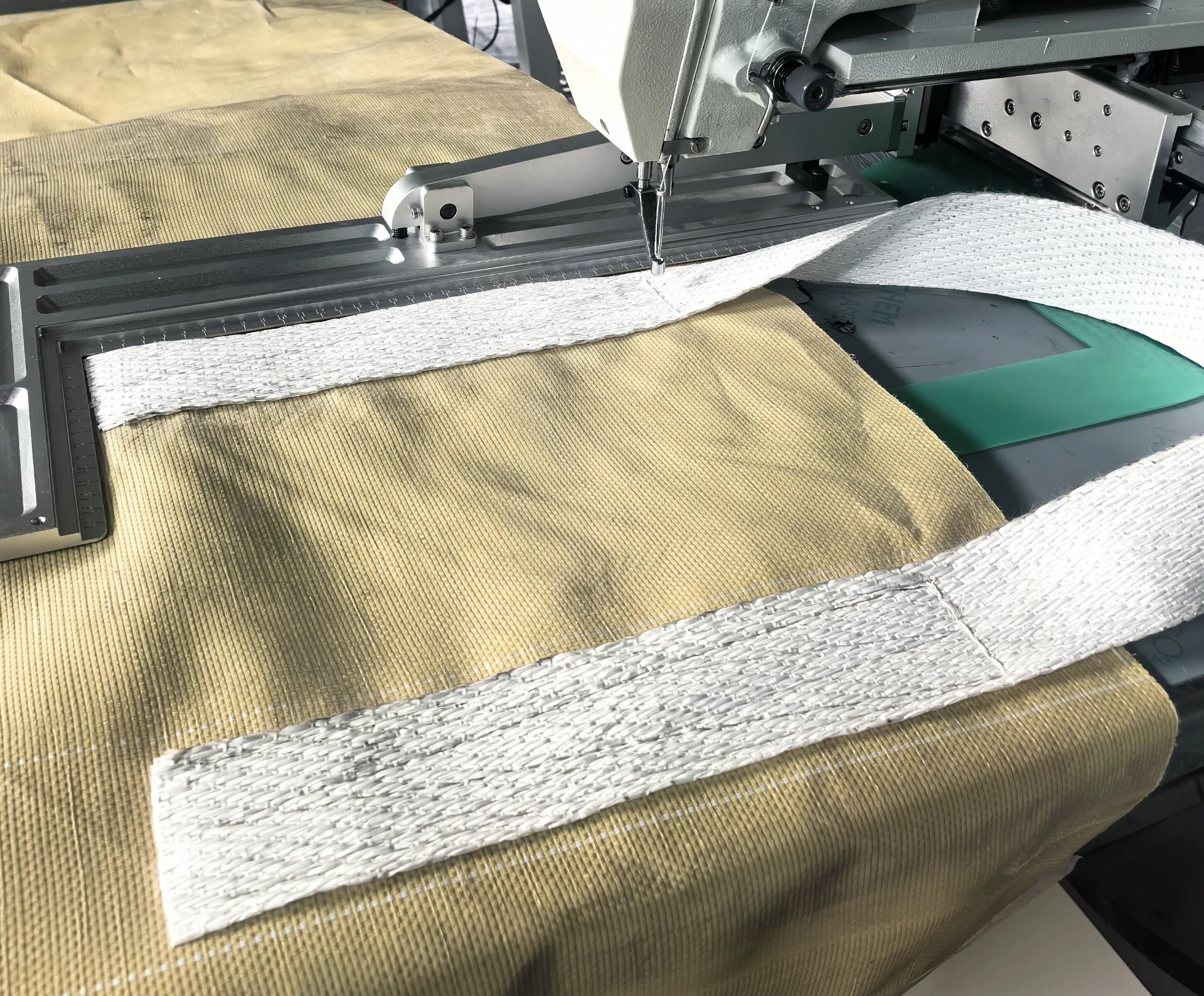

big bag sewing machine

In the fast-paced realm of industrial manufacturing, efficiency and precision are critical players. The big bag sewing machine stands as a hallmark of this dual necessity, revolutionizing the way bulk goods are packaged and transported. This powerful piece of equipment, often employed in industries ranging from agriculture to chemical production, presents itself as an indispensable tool engineered for excellence.

When discussing authoritativeness, the big bag sewing machine does not stand alone. Its reputation is linked to manufacturers renowned for producing reliable, high-performance equipment. Leading companies in the sector invest heavily in research and development, continually improving machine software and hardware to enhance durability, efficiency, and user interfaces. Such investments result in machines that not only meet but often exceed established industry standards. Trustworthiness is another critical pillar supporting the widespread adoption of big bag sewing machines. With the proper maintenance schedule and adherence to operating guidelines, these machines offer an exceptional lifespan, often without significant performance degradation. This reliability builds trust among users who depend on them for day-to-day operations, knowing their productivity and product quality won’t be compromised due to machinery malfunctions. Across industries, the big bag sewing machine continues to gain traction, offering a blend of advanced technology and practical design. It embodies a perfect synergy of automated precision and user adaptability, making it an essential acquisition for large-scale manufacturers. Selecting the right machine involves considering factors such as load capacity, compatibility with existing systems, and availability of technical support from the manufacturer. These considerations ensure not only a worthwhile investment but also seamless integration into current operations, thereby maximizing operational efficiencies and maintaining superior standards. Ultimately, the big bag sewing machine is more than just a tool; it is a testament to human ingenuity and our relentless pursuit of progress in industrial manufacturing. With each stitch, these machines weave a legacy of quality, reliability, and innovation.

When discussing authoritativeness, the big bag sewing machine does not stand alone. Its reputation is linked to manufacturers renowned for producing reliable, high-performance equipment. Leading companies in the sector invest heavily in research and development, continually improving machine software and hardware to enhance durability, efficiency, and user interfaces. Such investments result in machines that not only meet but often exceed established industry standards. Trustworthiness is another critical pillar supporting the widespread adoption of big bag sewing machines. With the proper maintenance schedule and adherence to operating guidelines, these machines offer an exceptional lifespan, often without significant performance degradation. This reliability builds trust among users who depend on them for day-to-day operations, knowing their productivity and product quality won’t be compromised due to machinery malfunctions. Across industries, the big bag sewing machine continues to gain traction, offering a blend of advanced technology and practical design. It embodies a perfect synergy of automated precision and user adaptability, making it an essential acquisition for large-scale manufacturers. Selecting the right machine involves considering factors such as load capacity, compatibility with existing systems, and availability of technical support from the manufacturer. These considerations ensure not only a worthwhile investment but also seamless integration into current operations, thereby maximizing operational efficiencies and maintaining superior standards. Ultimately, the big bag sewing machine is more than just a tool; it is a testament to human ingenuity and our relentless pursuit of progress in industrial manufacturing. With each stitch, these machines weave a legacy of quality, reliability, and innovation.

Previous:

Next:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025