Innovative Automatic Cutting and Sewing Technology for Efficient Textile Manufacturing

The Advancements and Benefits of Automatic Cutting and Sewing Machines

In the realm of textile manufacturing, the introduction of automatic cutting and sewing machines marks a significant shift toward efficiency, precision, and innovation. As global demand for garments continues to surge, these machines have emerged as essential tools for manufacturers looking to enhance production capabilities while maintaining high-quality standards.

The Evolution of Automatic Machines

Historically, garment production relied heavily on manual labor, which often led to inconsistencies and inefficiencies. As technology advanced, the development of automatic cutting and sewing machines began to transform the landscape of the textile industry. These machines utilize computer-controlled systems to manage complex tasks, allowing for meticulous cuts and precise stitching with minimal human intervention.

Automatic cutting machines employ sophisticated software to create cutting patterns that maximize fabric usage and reduce waste. They are equipped with high-speed blades that can cut through multiple layers of fabric simultaneously, significantly expediting the initial phase of garment production. This technology not only streamlines the cutting process but also enhances accuracy, as the machines are programmed to adhere to intricate designs and specifications, which is especially important for high-volume manufacturing.

Sewing machines have also benefitted from automation. Modern automatic sewing machines are designed to perform a variety of stitching types, catering to different fabric types and garment styles. They can automatically adjust their settings based on the materials being used, which minimizes the risk of errors and ensures consistent quality throughout production runs.

Benefits of Automatic Cutting and Sewing Machines

1. Increased Efficiency One of the foremost advantages of these machines is their ability to boost production speeds. Automatic cutting and sewing machines can perform tasks much faster than their manual counterparts, allowing manufacturers to meet tight deadlines and increasing their overall output.

2. Cost-Effective Although the initial investment in automated machinery can be significant, the long-term savings are substantial. By reducing labor costs and minimizing fabric waste through precise cutting patterns, manufacturers can significantly lower their operational expenses.

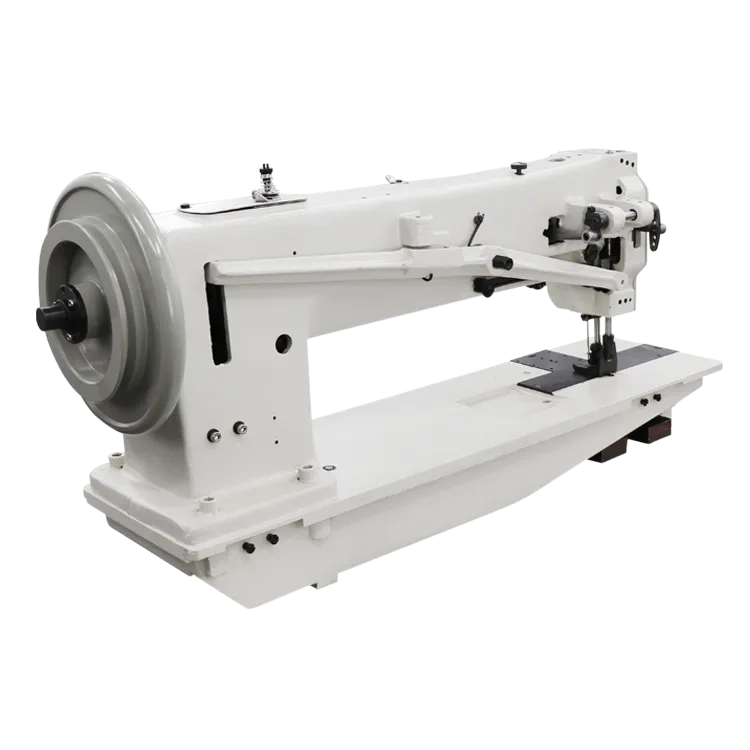

automatic cutting and sewing machine

3. Consistent Quality Automatic machines deliver unmatched precision and repeatability. This consistency is crucial in garment manufacturing, where even small deviations can lead to defects. By relying on automation, manufacturers can ensure that each piece produced meets the same high standards as the last.

4. Reduced Waste The software used in automatic cutting machines is designed to optimize fabric usage. By calculating the best layout for cutting, these machines minimize scrap material and reduce the environmental impact of textile production.

5. Enhanced Flexibility Many automatic cutting and sewing machines can be reprogrammed to accommodate different styles and fabric types. This flexibility allows manufacturers to quickly adapt to changing fashion trends and consumer demands without the need for extensive retooling or downtime.

Challenges and Considerations

While the benefits of automatic cutting and sewing machines are substantial, their implementation isn’t without challenges. The initial cost of purchasing and integrating these machines can be a barrier for smaller manufacturers. Additionally, the workforce may require training to operate and maintain high-tech equipment effectively.

Despite these challenges, the overall trajectory of the textile industry is leaning towards automation. As technology evolves, it is likely we will see even more sophisticated cutting and sewing machines that incorporate artificial intelligence and machine learning, further enhancing their capabilities and efficiency.

Conclusion

The advent of automatic cutting and sewing machines has revolutionized the textile manufacturing industry. By improving efficiency, reducing waste, and ensuring consistent quality, these machines are not just an asset but a necessity for modern garment production. As manufacturers continue to invest in technology, the future of clothing production looks poised for even greater advancements, transforming how we approach garment creation and consumption in the ever-evolving fashion landscape.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025