Feb . 13, 2025 15:23

Back to list

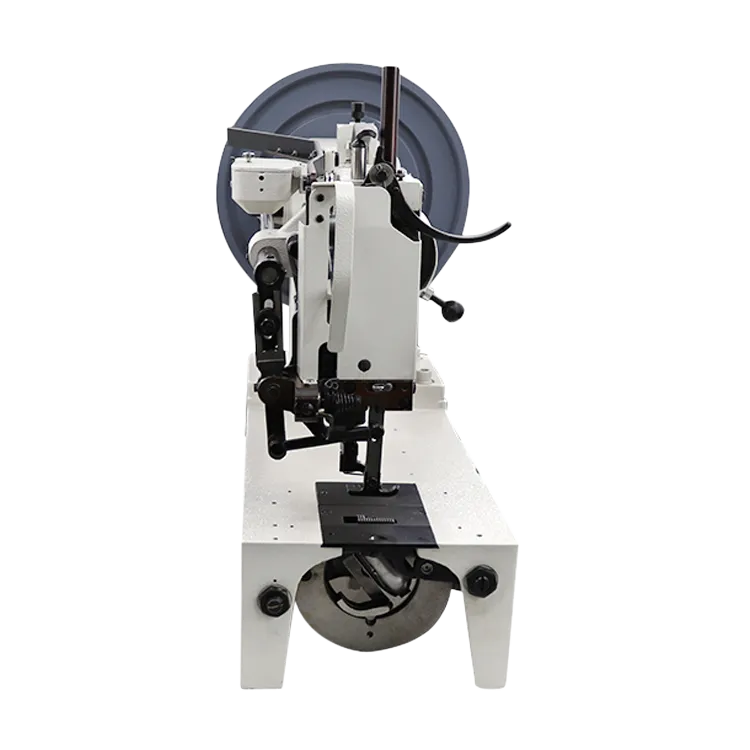

q bag baffle sew

Sewing leather on a sewing machine requires a delicate balance of skill, knowledge, and the right equipment. Leather, unlike fabric, presents unique challenges due to its thickness, texture, and durability. Understanding how to work with leather properly is crucial for anyone looking to craft beautiful, lasting products.

When it comes to stitching techniques, longer stitch lengths are generally preferred when working with leather. Short stitches can weaken the material and cause it to tear over time. A stitch length of 3.5 to 4 mm is often recommended. Topstitching, a technique where stitches are visible on the surface of the leather, can add a professional touch to leather projects. This technique not only reinforces seams but also enhances the aesthetic appeal of the finished product. One should never underestimate the importance of proper maintenance and care of both the sewing machine and the leather material. Regular cleaning and oiling of the sewing machine will ensure a smooth operation and prevent any potential damage from the leather fibers. As for the leather, keeping it clean and conditioned will preserve its natural oils and maintain its suppleness. Safety is paramount when sewing leather. Using thimbles, safety glasses, and maintaining a clutter-free work area can help prevent accidents. Moreover, working in a well-lit environment is essential to ensure precision and accuracy in your work. In pursuit of mastering leather sewing, one should consider investing time in practice and education. Resources such as workshops, online tutorials, and community groups can provide invaluable insights and techniques tailored to leatherwork. Engaging in a community of like-minded enthusiasts can also foster an exchange of tips and advice, enhancing one's craftsmanship. Finally, understanding the nuances of different leather types such as full-grain, top-grain, and genuine leather will further refine one’s sewing technique, as each type interacts differently with the sewing machine. This knowledge will empower you to select the best leather for your specific project, ensuring a combination of functionality and elegance in your creations. These comprehensive insights into sewing leather on a sewing machine will not only enhance your craftsmanship but also establish your authority in the field, allowing you to produce high-quality, durable leather products with confidence.

When it comes to stitching techniques, longer stitch lengths are generally preferred when working with leather. Short stitches can weaken the material and cause it to tear over time. A stitch length of 3.5 to 4 mm is often recommended. Topstitching, a technique where stitches are visible on the surface of the leather, can add a professional touch to leather projects. This technique not only reinforces seams but also enhances the aesthetic appeal of the finished product. One should never underestimate the importance of proper maintenance and care of both the sewing machine and the leather material. Regular cleaning and oiling of the sewing machine will ensure a smooth operation and prevent any potential damage from the leather fibers. As for the leather, keeping it clean and conditioned will preserve its natural oils and maintain its suppleness. Safety is paramount when sewing leather. Using thimbles, safety glasses, and maintaining a clutter-free work area can help prevent accidents. Moreover, working in a well-lit environment is essential to ensure precision and accuracy in your work. In pursuit of mastering leather sewing, one should consider investing time in practice and education. Resources such as workshops, online tutorials, and community groups can provide invaluable insights and techniques tailored to leatherwork. Engaging in a community of like-minded enthusiasts can also foster an exchange of tips and advice, enhancing one's craftsmanship. Finally, understanding the nuances of different leather types such as full-grain, top-grain, and genuine leather will further refine one’s sewing technique, as each type interacts differently with the sewing machine. This knowledge will empower you to select the best leather for your specific project, ensuring a combination of functionality and elegance in your creations. These comprehensive insights into sewing leather on a sewing machine will not only enhance your craftsmanship but also establish your authority in the field, allowing you to produce high-quality, durable leather products with confidence.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025