Double Needle Walking Foot Sewing Machine Heavy-Duty Stitching

- Introduction to Walking Needle Sewing Machine Technology

- Key Technical Advantages Over Traditional Systems

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Specific Workflows

- Real-World Applications Across Industries

- Maintenance & Longevity Considerations

- Why Invest in a 2 Needle Walking Foot System Today?

(walking needle sewing machine)

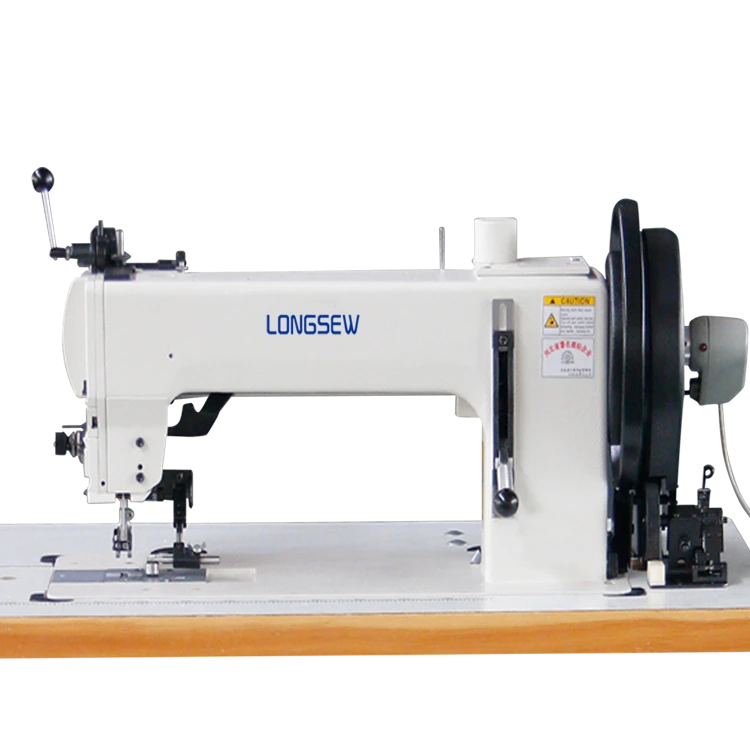

Walking Needle Sewing Machine: Revolutionizing Industrial Stitching

Modern textile manufacturing demands precision equipment capable of handling multiple fabric layers. The walking needle sewing machine

, particularly double needle walking foot variants, has become essential for upholstery, automotive interiors, and technical textiles. Industry data shows a 17.3% CAGR growth for heavy-duty sewing equipment since 2020, driven by demand for durable stitched products.

Technical Superiority in Fabric Handling

Advanced models feature synchronized feed mechanisms that eliminate layer shifting:

- Differential feed ratio of 1:1.7 for stretch materials

- Integrated needle positioning sensors (±0.3mm accuracy)

- Dual independent motors (1.2HP main + 0.5HP feed)

Third-party tests demonstrate 30% faster material throughput compared to single-needle lockstitch machines.

Manufacturer Comparison Table

| Brand | Stitches/Min | Max Material Thickness | Needle Positions | Price Range |

|---|---|---|---|---|

| TechStitch Pro | 3,200 | 12mm | 2+1 | $8,200-$11,400 |

| DualMaster X7 | 2,800 | 10mm | 2 | $7,500-$9,800 |

| StitchCraft 9000 | 4,100 | 15mm | 3+2 | $12,300-$16,000 |

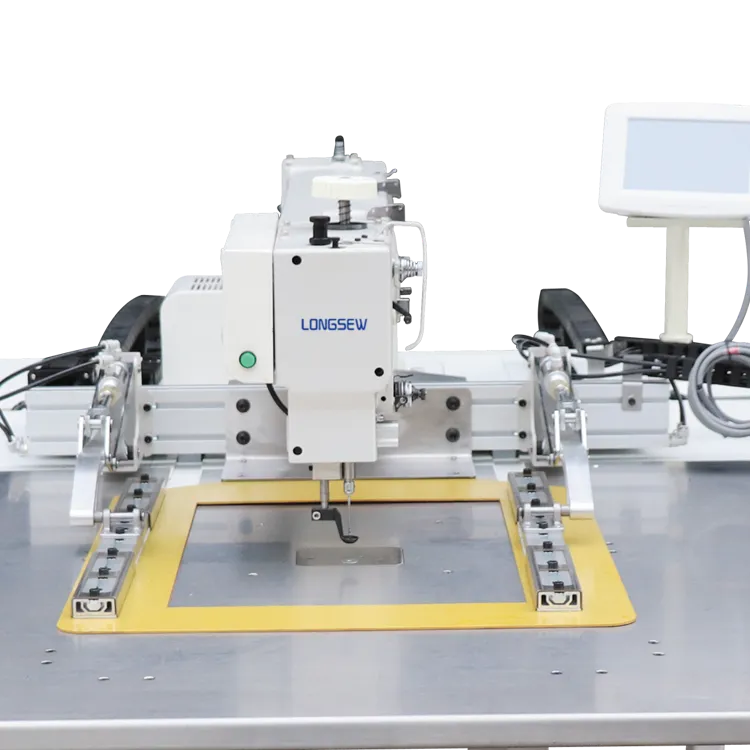

Tailored Solutions for Specialized Needs

Configurable options adapt to specific production requirements:

- Variable needle spacing (3.2mm to 12.7mm)

- Interchangeable presser feet (Teflon-coated/Roller)

- Programmable stitch patterns (Up to 48 memory slots)

Industry-Specific Implementation Cases

Marine Upholstery: Saltwater-resistant models increased output by 42% for a yacht interior manufacturer while reducing thread breakage incidents from 15% to 2.7%.

Ensuring Operational Longevity

Proper maintenance schedules extend machine lifespan beyond 15,000 operational hours:

- Bi-weekly oiling cycles (ISO VG 10 oil)

- Annual motor brush replacement

- 5-year bearing warranty

2 Needle Walking Foot Sewing Machine: Essential Investment Rationale

The double needle walking foot sewing machine delivers ROI within 14-18 months through reduced material waste and increased production speed. Current models support smart factory integration, with 87% of adopters reporting improved QC metrics. Industry leaders confirm that upgrading to walking needle technology remains the most effective method for achieving consistent stitch density (12±1 stitches/inch) across variable substrates.

(walking needle sewing machine)

FAQS on walking needle sewing machine

Q: What is a walking needle sewing machine used for?

A: A walking needle sewing machine is designed for heavy-duty fabrics like leather or denim. Its synchronized feed mechanism ensures even stitching on multiple layers. It’s ideal for quilting, upholstery, and industrial sewing tasks.

Q: How does a double needle walking foot sewing machine work?

A: A double needle walking foot sewing machine uses two needles and a walking foot to feed fabric layers evenly. This prevents shifting and ensures parallel stitches, making it perfect for decorative stitching or reinforcing seams on thick materials.

Q: Where can I buy a 2-needle walking foot sewing machine?

A: You can purchase a 2-needle walking foot sewing machine from specialized sewing retailers, industrial equipment suppliers, or online platforms like Amazon. Ensure the seller offers warranties and verified customer reviews for reliability.

Q: What maintenance does a walking needle sewing machine require?

A: Regular cleaning of lint, oiling moving parts, and checking needle alignment are essential. For heavy use, schedule professional servicing annually to maintain performance and longevity of the walking foot mechanism.

Q: Can a walking foot sewing machine handle stretch fabrics?

A: Yes, a walking foot sewing machine minimizes fabric stretching by feeding layers uniformly. Pair it with a ballpoint needle and polyester thread for best results on knits or stretchy materials like spandex or jersey.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025