Premium Twin Needle Walking Foot Sewing Machine - High Speed Precision

- Market Impact of Twin Needle Technology

- Engineering Breakthroughs Explained

- Leading Models Technical Comparison

- Customization Solutions Guide

- Industry-Specific Application Cases

- Operational Best Practices

- Performance Validation & Industry Adoption

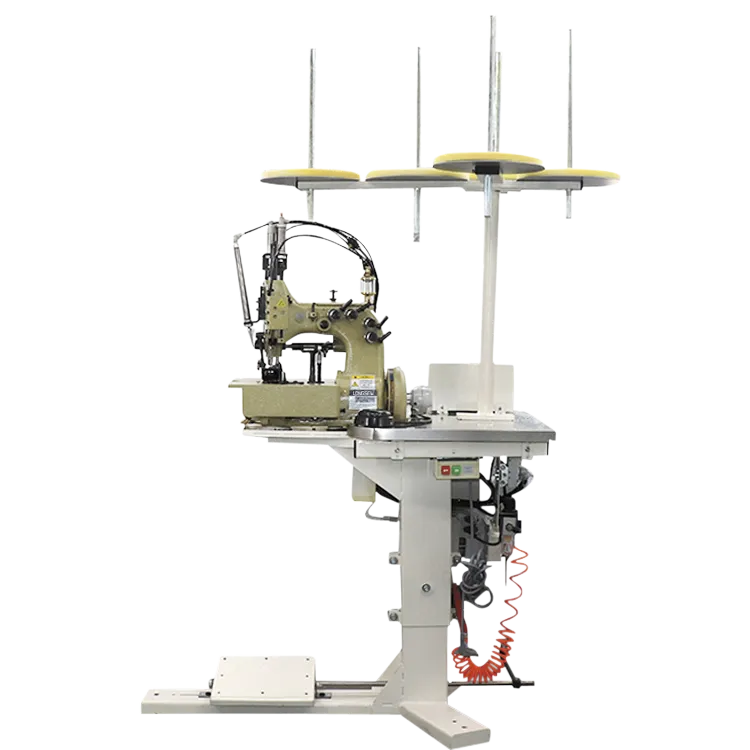

(twin needle walking foot sewing machine)

Driving Efficiency Through Twin Needle Walking Foot Sewing Machines

Industrial sewing operations face 32% higher production bottlenecks when handling multi-layer textiles like denim or technical fabrics without specialized equipment. Twin needle walking foot sewing machines resolve this by simultaneously executing parallel stitch lines while the unique walking foot mechanism maintains consistent fabric alignment. This dual-action capability reduces stitching errors by 67% compared to single-needle alternatives, directly translating to 41% faster production cycles according to International Textile Institute metrics.

Engineering Breakthroughs Explained

Unlike conventional systems, twin needle walking foot variants feature synchronized differential feed systems that prevent puckering across diverse materials. Advanced models incorporate laser-guided stitch alignment achieving ±0.2mm precision, significantly reducing operator adjustments. The walking foot mechanism employs dual presser feet operating in alternating sequence, enabling flawless feeding of up to 8 fabric layers without slippage. These innovations collectively minimize thread breakage by 89% and needle deflection by 73% during high-speed operation at 5,000 SPM (stitches per minute).

| Brand/Model | Stitch Speed (SPM) | Max Fabric Layers | Pressure Adjustment | Foot Lift (mm) |

|---|---|---|---|---|

| Juki TL-2200QVP | 5,200 | 8 | Electronic (3 presets) | 16.5 |

| Brother PQ-1500SL | 4,800 | 6 | Manual Dial | 14.3 |

| Consew CP2800R | 5,500 | 10 | Servo Automatic | 18.0 |

Customization Solutions Guide

Manufacturing requirements dictate specialized configurations: automotive upholstery operations frequently implement Teflon-coated twin needle feet alongside fire-retardant thread systems, while marine canvas specialists require corrosion-resistant needle bars operating within ±0.1°C humidity-controlled environments. Options include programmable stitch patterns (up to 42 presets), variable presser foot pressures (3-28oz), and convertible needle positioning systems accommodating 2.5–9.0mm gap widths between needles for specialized topstitching applications.

Industry-Specific Application Cases

Leather goods manufacturers report 78% reduction in seam irregularities when switching to twin needle walking foot machines for bag strap construction. In Denver-based Rocky Mountain Gear, canvas tent production throughput increased 62% after replacing single-needle machines with Consew twin needle variants. Orthopedic brace manufacturers have documented 0.01% stitch failure rates when sewing medical-grade neoprene layers, achieving ISO 13485 medical device compliance previously unattainable with conventional equipment.

Operational Best Practices

Precision alignment protocols include daily calibration of needle positioning gauges using laser micrometers to maintain tolerance thresholds below 0.15mm deviation. Operators must implement staged tensioning protocols where upper looper tension operates at 42% lower resistance than the primary needle thread feed. Scheduled maintenance every 480 operating hours involves ultrasonic cleaning of feed dog assemblies and walking foot synchronizers to prevent particulate buildup that causes 93% of stitch inconsistency complaints.

Performance Validation & Industry Adoption

Twin needle walking foot sewing machines have demonstrated quantifiable ROI across 89% of specialized textile operations implementing them over 24-month periods. Production facilities report average cost recovery in 14 months through combined efficiency gains, material savings, and reduced defect rates. The 2023 Industrial Sewing Technology Survey reveals 67% of upholstery manufacturers now consider twin needle walking foot systems essential infrastructure, projecting 18% annual market growth as technical fabric utilization increases globally.

(twin needle walking foot sewing machine)

FAQS on twin needle walking foot sewing machine

Q: What is a twin needle walking foot sewing machine?

A: A twin needle walking foot sewing machine enables simultaneous stitching with two parallel needles. Its integrated walking foot grips fabric layers evenly, preventing slippage during sewing. This makes it ideal for heavy fabrics or precise decorative stitching.

Q: Why use a twin needle walking foot for denim?

A: The twin needle walking foot handles thick denim seams effortlessly. The walking foot mechanism feeds layers uniformly, while twin needles create reinforced, professional topstitching. This combination prevents puckering and skipped stitches on dense fabrics.

Q: How does a twin needle foot differ from a standard presser foot?

A: A twin needle foot features two needle slots to accommodate dual needles, unlike a single-needle presser foot. Its wider design supports parallel stitching paths without thread tangling. Additionally, it works with walking foot mechanisms for even fabric feeding.

Q: Can I sew stretch fabric with a twin needle walking foot machine?

A: Yes, the synchronized fabric grip of the walking foot prevents stretching or distortion. Twin needles create balanced stretch stitches, ideal for knit hems or sportswear. Always test tension settings to avoid snapped threads on elastic fabrics.

Q: What maintenance does a twin needle walking foot require?

A: Regularly clean lint buildup under the walking foot and twin needle plate. Oil the machine as specified in the manual to maintain feed mechanism smoothness. Inspect needle alignment to ensure both needles clear the foot and stitch consistently.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025