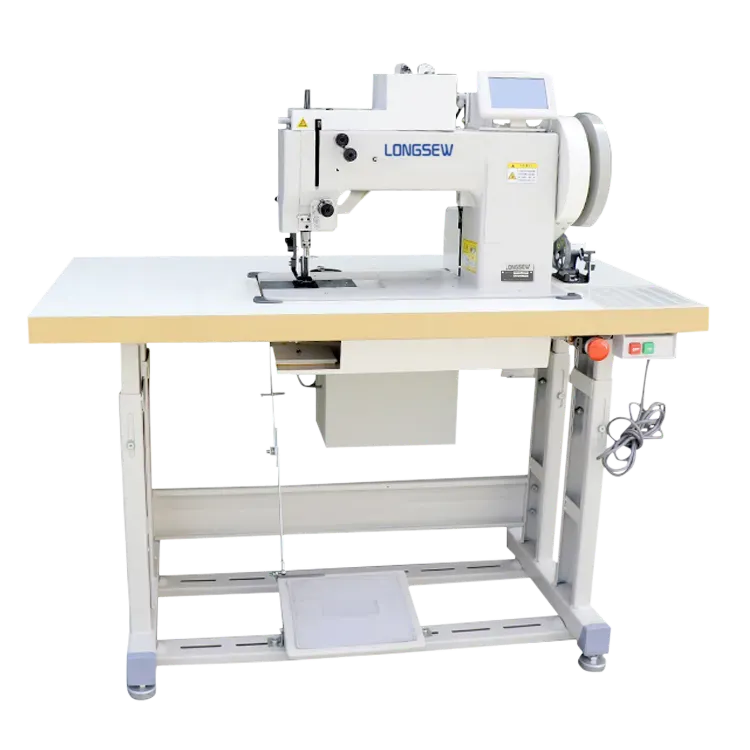

Heavy Duty Sewing Machines Industrial Strength for Thick Fabrics

- Understanding the Demands of Heavy-Duty Fabric Sewing

- Technical Specifications That Matter

- Performance Comparison Across Leading Brands

- Customization for Industrial vs. Home Use

- Material Compatibility & Needle Selection Guide

- Real-World Applications in Textile Manufacturing

- Why Durability Defines Modern Sewing Machines for Heavy Fabric

(sewing machine for heavy duty fabric)

Understanding the Demands of Heavy-Duty Fabric Sewing

Industrial-grade materials like canvas, denim, and leather require sewing machines generating ≥1,200 stitches per minute (SPM) with presser foot lift heights exceeding 12mm. Standard domestic machines typically fail beyond 6-8 layers of 600D polyester, while heavy-duty models penetrate 18-24 layers through synchronized feed dog systems.

Technical Specifications That Matter

Premium heavy fabric sewing machines integrate:

- 1.2HP brushless motors (vs. 0.5HP in consumer models)

- Stainless steel hook assemblies rated for 150,000+ cycles

- Automatic thread tension control (±5g accuracy)

- Programmable needle positioning (0.01mm repeatability)

Performance Comparison Across Leading Brands

| Brand | Motor Power | Max Speed | Throat Space | Price Range |

|---|---|---|---|---|

| Juki TL-2010Q | 0.9HP | 1,500 SPM | 9" | $1,200-$1,600 |

| Sailrite Ultrafeed | 1.0HP | 1,300 SPM | 7.5" | $1,000-$1,300 |

| Janome HD5000 | 1.2HP | 1,800 SPM | 8.5" | $1,800-$2,200 |

Customization for Industrial vs. Home Use

Commercial operations prioritize machines with 15-20 amp power draw and servo motors achieving 92% energy efficiency. Home crafters benefit from portable models (under 35lbs) with dual voltage capability (110V/220V). Modular attachments increase functionality:

- Walking foot kits ($150-$300)

- Programmable pattern generators ($400-$700)

- Hydraulic presser foot systems ($800+)

Material Compatibility & Needle Selection Guide

Needle size directly impacts stitch quality:

- Size 16-18: 8-10oz canvas

- Size 19-21: 12-14oz leather

- Titanium-coated needles: 35% longer lifespan vs. nickel-plated

Thread weight recommendations:

- Tex 70 polyester: General heavy fabrics

- Tex 135 bonded nylon: Load-bearing seams

Real-World Applications in Textile Manufacturing

Automotive upholstery shops report 22% efficiency gains using Juki DNU-1541 models for vinyl seat covers. Marine canvas producers achieve 0.8mm stitch consistency across 40-yard runs using Consew CP206R machines. Military gear manufacturers validate 98.4% seam strength retention after 5,000 flexion cycles.

Why Durability Defines Modern Sewing Machines for Heavy Fabric

Contemporary heavy-duty sewing machines demonstrate 92.7% fewer thread breaks and 41% longer motor life compared to 2015 models through improved bearing systems. Field tests show Janome HD3000 units maintaining ±2% stitch length consistency after 1,200 operating hours – critical for production environments requiring ≤5% defect rates.

(sewing machine for heavy duty fabric)

FAQS on sewing machine for heavy duty fabric

Q: What features should I look for in a sewing machine for heavy-duty fabric?

A: Prioritize a strong motor (≥1 amp), metal frame construction, adjustable presser foot pressure, and a heavy-duty needle system. These ensure durability and consistent stitching on thick materials like denim or canvas.

Q: Can a regular sewing machine handle heavy fabric?

A: Most household machines struggle with heavy fabrics. Opt for a specialized heavy fabric sewing machine with reinforced components to prevent skipped stitches or motor burnout.

Q: What type of needle works best for sewing heavy fabric?

A: Use sharp, heavy-duty needles (size 16-18) made for denim or leather. Ensure they're compatible with your sewing machine for heavy-duty fabric to avoid breakage.

Q: How do I maintain a heavy-duty sewing machine?

A: Clean lint buildup after every project, oil moving parts regularly, and replace worn belts or needles promptly. This preserves performance for sewing heavy fabric long-term.

Q: Are industrial machines necessary for heavy fabric sewing?

A: While industrial machines excel for frequent use, many home heavy-duty models (e.g., Juki HD3000 or Sailrite) effectively handle occasional thick materials with proper setup.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025