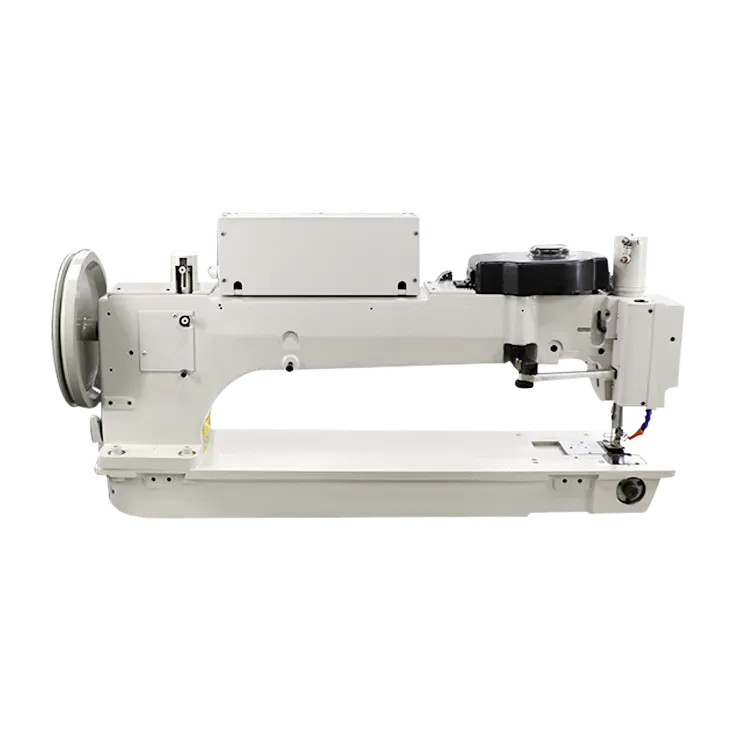

pattern sewing machine for shoes

The Evolution of Pattern Sewing Machines for Shoes

In the realm of footwear manufacturing, precision and efficiency are paramount. As the industry evolves, so do the tools used by craftsmen and manufacturers to create high-quality shoes. Among these tools, the pattern sewing machine stands out as a vital piece of equipment, designed specifically to meet the unique requirements of shoe production.

Pattern sewing machines have significantly advanced over the years, transforming the way shoes are manufactured. Initially, traditional sewing techniques relied heavily on manual labor, where artisans would painstakingly stitch together shoe components by hand. While this method allowed for intricacy and personalization, it was also time-consuming and limited in scalability. Recognizing the need for innovation, manufacturers began developing specialized sewing machines tailored for pattern sewing.

These machines are engineered to handle various materials commonly used in shoe production, such as leather, synthetic fabrics, and canvas. They are equipped with advanced features that enhance their functionality, including automatic thread tension control, programmable stitching patterns, and adjustable needle positions. Such innovations allow for consistent quality, reduced production time, and the ability to produce complex designs with ease.

One of the key advantages of pattern sewing machines is their automation capabilities. By incorporating computer numerical control (CNC) technology, manufacturers can precisely program the machines to replicate intricate designs that would be nearly impossible to achieve by hand. This automation not only increases efficiency but also minimizes human error, ensuring that each shoe meets the desired specifications.

pattern sewing machine for shoes

Moreover, pattern sewing machines have become instrumental in the customization trend that is currently sweeping the fashion industry. With consumers seeking unique and personalized footwear options, manufacturers can now offer bespoke services using these machines. Customers can choose their desired patterns, fabrics, and colors, and the automated sewing process allows for rapid production without compromising quality.

Sustainability is also an increasingly important consideration in modern shoe manufacturing. Pattern sewing machines can contribute to a more sustainable production process by optimizing material usage, resulting in less waste. By accurately cutting and sewing patterns, manufacturers can maximize the yield from raw materials, thus reducing the environmental impact of shoe production.

As the industry continues to embrace technological advancements, the future of pattern sewing machines looks promising. Innovations such as 3D printing and smart manufacturing are on the horizon, potentially revolutionizing the way shoes are designed and produced. Nonetheless, the fundamental role of pattern sewing machines in ensuring efficiency, precision, and quality cannot be overstated.

In conclusion, pattern sewing machines for shoes have undergone a remarkable evolution, significantly enhancing the footwear manufacturing process. With their advanced capabilities, these machines not only improve efficiency and precision but also cater to the growing demand for customization and sustainability in the industry. As we look ahead, it is clear that the integration of technology will continue to shape the future of shoe production, making these machines an essential component of any forward-thinking manufacturing operation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025