leather sewing machine belts

The Importance of Leather Sewing Machine Belts

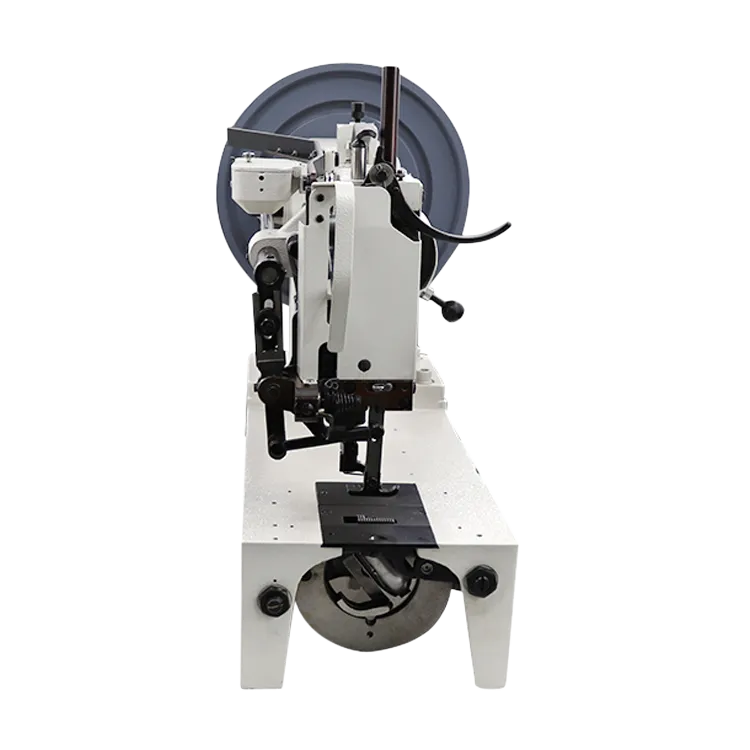

Leather sewing machine belts play a crucial role in the operation and efficiency of sewing machines, especially those that are designed for leatherwork. These belts are essential components that enable the machine to transfer motion from the motor to the needle mechanism, ensuring that the sewing process runs smoothly and effectively. In this article, we will explore the significance of leather sewing machine belts, the types available, and tips for their maintenance.

When it comes to sewing leather, precision and durability are paramount. Leather is a heavy material that requires a powerful sewing machine equipped with a robust belt to handle the tension and strain during the sewing process. Leather sewing machine belts are typically made from high-quality materials such as rubber or leather itself, designed to withstand the rigors of heavy-duty sewing while providing the necessary grip and flexibility.

There are several types of sewing machine belts available in the market. The most common types are flat belts, round belts, and V-belts. Flat belts are often used in traditional sewing machines and provide uniform tension across the width of the belt. Round belts, on the other hand, are flexible and can make tight turns, making them ideal for compact sewing machine designs. V-belts are designed to fit in specific grooves, which helps them stay aligned and provides an increased surface area for grip, essential for machines requiring more torque.

leather sewing machine belts

Maintaining your leather sewing machine belt is vital for ensuring the longevity and efficiency of your equipment. Regularly inspecting the belt for signs of wear, such as cracks, fraying, or loss of tension, is crucial. If you notice any damage, it is best to replace the belt promptly to avoid further complications, such as misalignment or machine malfunctions. Additionally, keeping the belt clean from dust and debris will enhance its performance and lifespan.

Another important tip is to periodically check the tension of the belt. Too much tension can lead to excessive wear on both the belt and the sewing machine components, while too little tension may result in slippage and inconsistent stitching. Adjusting the tension according to the manufacturer’s specifications can significantly improve sewing results.

In conclusion, leather sewing machine belts are indispensable for those engaged in leather sewing. They ensure the machine operates efficiently, allowing for precise and high-quality stitching. By understanding the types of belts available and adhering to proper maintenance practices, sewists can prolong the life of their machines and achieve the best results possible in their leather projects. Whether you’re a hobbyist or a professional, taking care of your sewing machine belt is a step toward successful leatherworking.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025