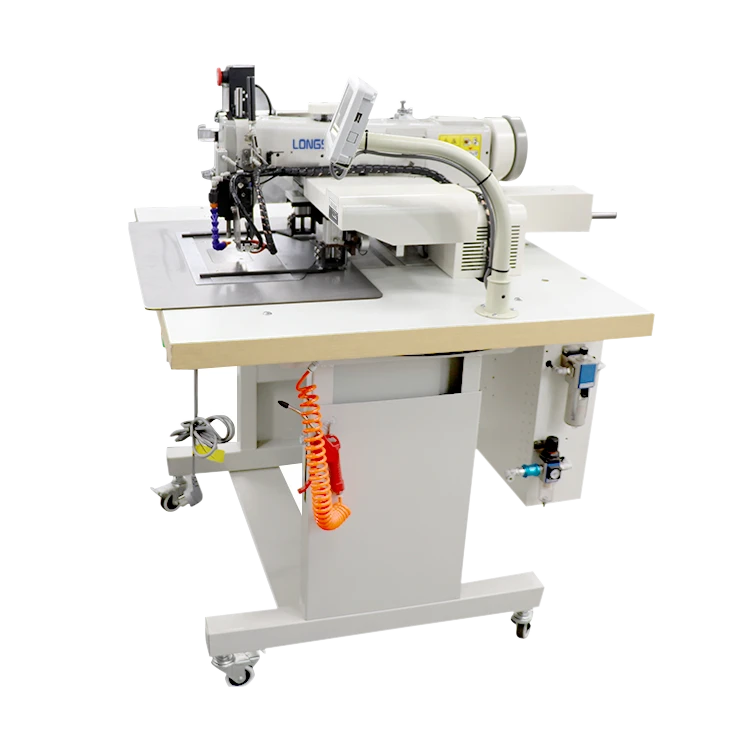

fibc spout sewing machine

The Importance of FIBC Spout Sewing Machines in Modern Industry

In today’s fast-paced industrial landscape, efficiency and durability are paramount. One area where these factors are crucial is in the packaging of bulk materials. Flexible Intermediate Bulk Containers (FIBCs), commonly referred to as bulk bags, have risen in popularity due to their ability to handle large quantities of dry bulk materials safely and efficiently. In the production of these bags, the role of FIBC spout sewing machines cannot be overstated, as they are integral to ensuring that these containers are manufactured to meet industry standards while maintaining economic efficiency.

FIBC bags are designed with a spout or opening that facilitates easy filling and emptying of materials. This design not only enhances usability but also minimizes waste, making them an eco-friendly choice for companies looking to reduce their carbon footprint. The spouts can vary in size and design depending on the specific application, making the precision in sewing these spouts critical. This is where FIBC spout sewing machines come into play.

The Importance of FIBC Spout Sewing Machines in Modern Industry

One of the key advantages of using FIBC spout sewing machines is their speed and efficiency. In a manufacturing environment where time is money, the ability to quickly sew spouts without sacrificing quality is invaluable. Advanced FIBC sewing machines are equipped with high-speed sewing capabilities, allowing businesses to increase their production rates while maintaining high standards. This efficiency helps manufacturers keep up with demand in industries such as agriculture, construction, and chemicals, where bulk packaging is essential.

fibc spout sewing machine

Moreover, modern FIBC sewing machines often come with automated features that further enhance productivity. These machines can be programmed to perform specific sewing patterns and adjust to different sizes of spouts, minimizing the need for manual intervention. This not only reduces the likelihood of human error but also frees up skilled workers to focus on more intricate tasks within the manufacturing process.

Sustainability is another significant consideration in today’s industrial practices. The production of FIBCs using high-quality spout sewing machines allows for the creation of bags that are not only durable but also recyclable. As more companies aim to adopt sustainable practices, investing in efficient and reliable sewing technology is a step toward achieving these environmental goals.

Additionally, the use of FIBC spout sewing machines contributes to the longevity of the bags produced. By ensuring that seams are well-constructed, manufacturers can produce FIBCs that withstand wear and tear during transport and storage. This reliability is critical for companies that need to transport hazardous materials or delicate products, as it minimizes the risk of leaks or breakages.

In conclusion, FIBC spout sewing machines play a vital role in the packaging industry by enhancing the efficiency and reliability of bulk bag production. As demand for FIBC bags continues to grow, driven by their versatility and eco-friendly profile, the significance of employing advanced sewing technology becomes increasingly clear. With features that promote speed, accuracy, and sustainability, these machines are an indispensable asset for manufacturers looking to thrive in a competitive market. Investing in high-quality FIBC spout sewing machines not only boosts productivity but also ensures a commitment to quality and environmental responsibility, paving the way for a successful future in bulk packaging.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025