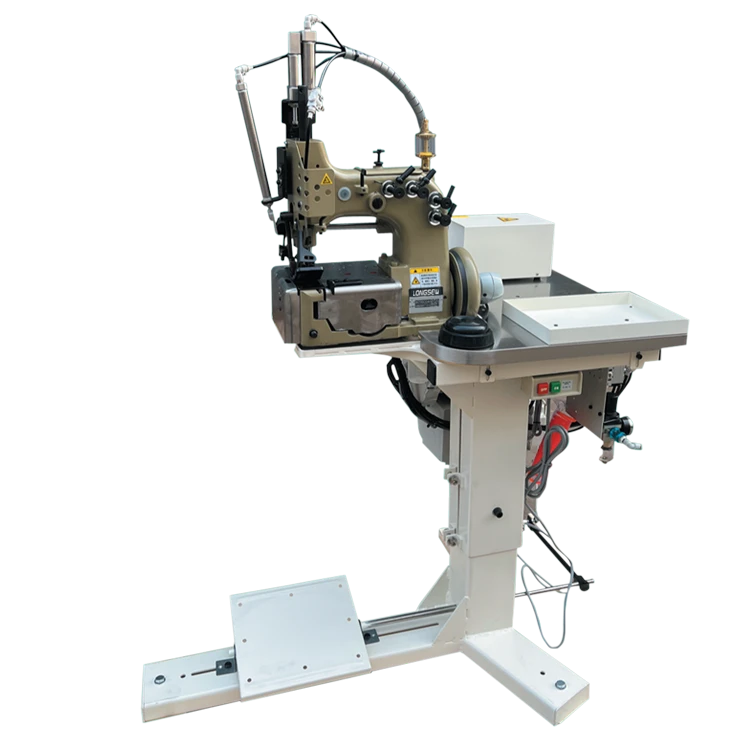

fibc sewing machine

Leveraging FIBC sewing machines in manufacturing processes represents a sophisticated development in the world of industrial packaging. These sewing machines, specifically designed for the fabrication of Flexible Intermediate Bulk Containers (FIBCs), are integral to producing robust and reliable bulk containers, capable of handling heavy loads with safety and efficiency.

The production of FIBCs involves the precise art of sewing, demanding machines that deliver straight, consistent stitches capable of withstanding considerable stress. The integrity of these containers hinges on the dependability of the seam. Quality sewing machines ensure the longevity and durability of the FIBCs, crucial for industries like agriculture, chemicals, and construction, which frequently rely on bulk shipping solutions.

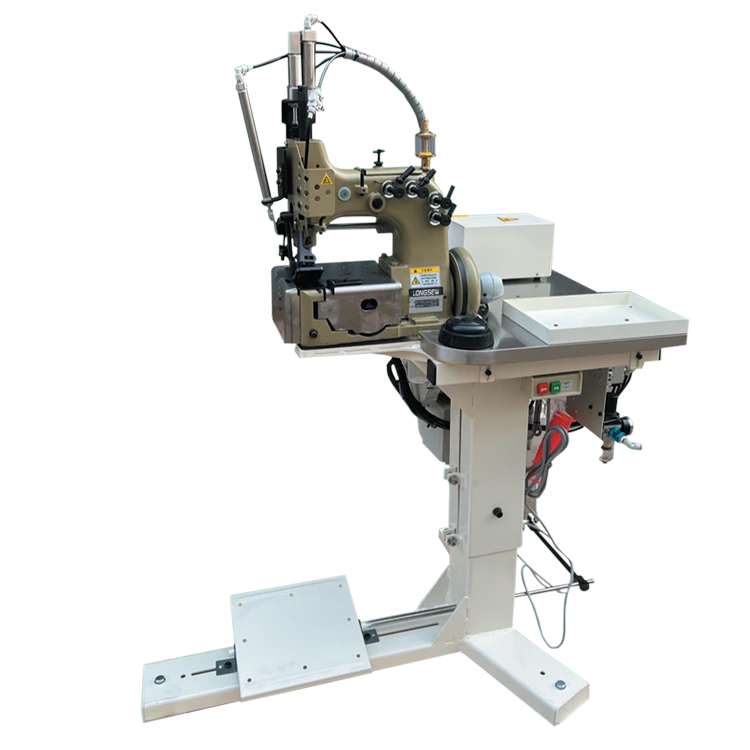

Expertise in the operation of FIBC sewing machines is essential. Operators must possess an in-depth understanding of the various stitch patterns and techniques that are most effective for different material types and container specifications. Training is critical, ensuring that operators can adjust machine settings according to the specific demands of each job, maintaining high standards of safety and quality.

Manufacturers often recommend in-house training sessions and certifications for operators to keep them abreast of the latest technologies and methodologies. Some advanced FIBC sewing machines come equipped with programmable features, allowing for customization and automation, which significantly enhances production efficiency and consistency.

fibc sewing machine

From an authoritative perspective, leading equipment manufacturers continually innovate to improve the functionality and reliability of FIBC sewing machines. These improvements often include features such as enhanced tension control, automatic thread cutting, and ergonomic designs to reduce operator fatigue. The addition of digital interfaces and IoT capabilities can provide real-time data analytics, helping businesses make informed decisions about operations and maintenance.

Trustworthiness in choosing the right FIBC sewing machine supplier is paramount for companies aiming to maintain competitive advantages. Reputable manufacturers typically offer comprehensive after-sales support, including maintenance services and spare parts availability, ensuring that their machines remain operational for extended periods. Partnering with such trustworthy suppliers can prevent costly downtime and production setbacks, establishing a reliable supply chain.

Overall, when considering an investment in FIBC sewing machines, businesses must evaluate not only the immediate cost but also the long-term benefits of improved efficiency, enhanced safety features, reduced operational downtime, and minimal maintenance requirements. A well-selected sewing machine can result in substantial cost savings over time, as well as a consistent product quality, which is essential for maintaining customer satisfaction and brand reputation.

In conclusion, FIBC sewing machines are not merely tools; they are pivotal assets in bulk container manufacturing. They play a crucial role in ensuring the structural integrity and safety of the containers produced. A focus on experience, expertise, authoritativeness, and trustworthiness in selecting and using FIBC sewing machines will significantly enhance a company's production capabilities and market standing. Leading players in the industry understand that their choice of machinery reflects directly on their product's and company's quality, underscoring the importance of investing in the best available technology complemented by operator expertise.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025