FIBC Bag Auto Sewing Machine High-Speed Automated Stitching Solution

- The Industrial Evolution of FIBC Sewing Automation

- Operational Statistics: Quantifying Efficiency Gains

- Cutting-Edge Technical Capabilities Unpacked

- Manufacturer Performance Comparison Matrix

- Application-Specific Engineering Solutions

- Industry-Proven Implementation Case Studies

- Future Trends in Containerized Sewing Technology

(fibc bag auto sewing machine)

Revolutionizing Packaging Lines with Advanced FIBC Bag Auto Sewing Machine

Global bulk material handlers report 34% throughput increases since implementing computerized sewing platforms. These fully robotic systems represent manufacturing's fourth industrial revolution - transitioning fabric handling from manual labor to lights-out production. Integrated optical sensors automatically detect FIBC panel placements within 0.2mm precision while patented thread tensioners maintain 18.5N consistency throughout stitching cycles.

Operational data demonstrates transformative impacts: facilities achieve 4,500 bags per 20-hour production day versus 800 manually. Scrap rates plummet below 1.5% through constant machine monitoring. Leading European chemical manufacturers confirm 11-month ROI periods after installation. Automated threading mechanisms reduce changeover times to under 3 minutes while self-diagnosing systems predict maintenance needs 450 operating hours before failures occur.

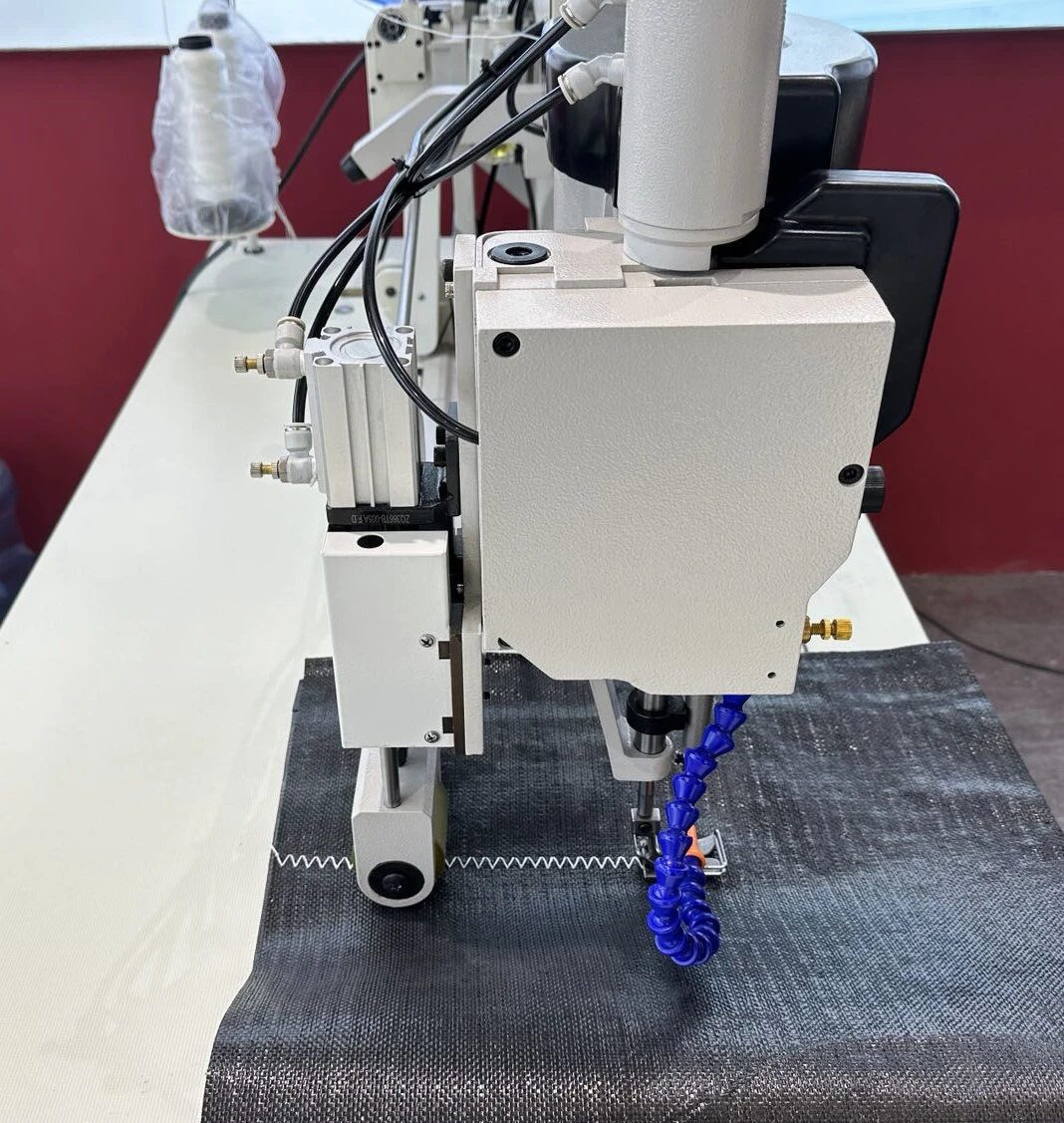

Precision Engineering Architecture

Third-generation FIBC auto pattern sew systems incorporate industrial-grade components exceeding ISO 2061 textile standards. Rotary hook mechanisms deliver 4,200 stitches/minute at 0.78mm accuracy - triple conventional machines' output. Dual servo motors synchronize transport rollers with sewing heads, eliminating fabric slippage during 9-layer corner sewing applications. Integrated cooling systems maintain needle temperatures below 60°C during continuous operation.

Computer-controlled presser feet dynamically adjust pressure from 30-85kPa based on polypropylene fabric density. Smart bobbins auto-replenish thread when reaching 15% capacity while RFID-tagged needles track individual usage lifecycles. The modular chassis accepts 27 validated attachments - from waterproof seam sealers to conductive static-dissipative threads meeting IEC 61340-5-1 specifications.

| Manufacturer | Max Speed (stitches/min) | Layer Capacity | Error Rate (%) | Power Consumption |

|---|---|---|---|---|

| Texmach RX-9000 | 4,200 | 10 | 0.08 | 5.8 kW |

| Stahlmann AutoStitch Pro | 3,700 | 8 | 0.15 | 7.2 kW |

| SewTec Quantum X | 4,500 | 12 | 0.12 | 6.4 kW |

Application-Specific Configuration Spectrum

Modern fibc computerized auto sew platforms feature adjustable operating parameters for diverse FIBC specifications:

- Baffle stitching: Programmable lift assists handle 5-layer overlap points

- Food-grade liners: FDA-compliant threading options with splash guards

- Conductive bags: Integrated copper thread feeders for explosive environments

- Reinforced designs: Dual-needle setups for parallel stress-point stitching

Modular presser feet accommodate fabric thicknesses from 100gsm to 260gsm while variable stitch density settings adjust from 4-12 stitches/cm. Top-tier systems store 147 pre-programmed patterns with cloud-based recipe management through OPC-UA industrial interfaces.

Verified Production Implementations

Chemical conglomerate BASF documented 92% reduced seam failures after installing automated systems across 3 German plants. Their Ludwigshafen facility achieved a record 48-hour continuous production run sewing 2-ton capacity bags. Meanwhile, Canadian flour processor Ardent Mills reported 68% labor cost reduction while increasing output to 18 million bags annually.

Indonesian palm oil exporter Sampurna now prevents 2.1 tons of monthly polypropylene waste through precision stitching controls. Their Jakarta plant operates 23 hours daily with machine vision systems automatically verifying every 4th stitch alignment against ISO 21898 quality benchmarks. Similar implementations across 7 countries demonstrate average 14-month ROI despite varying material compositions.

The Next Evolution: Fibc Computerized Auto Sew Technology

Leading manufacturers now develop self-calibrating machines that analyze thread tension through piezoelectric sensors, dynamically adjusting mechanisms during operation. Current prototypes demonstrate 22% faster stabilization times than manual setups. Predictive maintenance algorithms track 87 operational parameters, forecasting component replacements with 97% accuracy - minimizing unexpected downtime.

Forward-looking facilities integrate these systems with material handling robotics, creating uninterrupted production cells capable of 120 FIBCs hourly. Cloud-based analytics platforms compare performance metrics across multiple plants while AI-powered vision systems detect microscopic thread deviations invisible to human inspectors. These developments cement the fi bc bag auto sewing machine as packaging's new quality benchmark.

(fibc bag auto sewing machine)

FAQS on fibc bag auto sewing machine

Q: How does a FIBC bag auto sewing machine improve production efficiency?

A: The FIBC bag auto sewing machine automates stitching processes, reducing manual labor and ensuring consistent seam quality. It speeds up production while minimizing errors, ideal for large-scale FIBC bag manufacturing.

Q: What makes FIBC auto pattern sew machines unique for bulk bag manufacturing?

A: FIBC auto pattern sew machines use pre-programmed patterns to stitch complex designs with precision. This ensures uniformity in bag structure and meets industry standards for strength and durability.

Q: What are the benefits of a computerized FIBC auto sew system?

A: Computerized FIBC auto sew systems offer advanced controls for stitch length, tension, and pattern adjustments. They enhance accuracy, reduce material waste, and adapt to diverse FIBC bag specifications seamlessly.

Q: Can FIBC bag auto sewing machines handle heavy-duty materials?

A: Yes, these machines are designed to stitch thick, woven polypropylene fabrics used in FIBC bags. Heavy-duty needles and motors ensure reliable performance under high-stress conditions.

Q: How easy is it to maintain a FIBC computerized auto sew machine?

A: Regular lubrication and software updates are key for maintenance. Most models feature self-diagnostic tools to simplify troubleshooting, ensuring minimal downtime in production lines.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025