Advanced Composite Sewing Machines for Enhanced Fabric Manipulation and Performance Efficiency

The Versatility of Compound Sewing Machines

In the world of textile manufacturing and garment production, efficiency and precision are paramount. Amidst the myriad of sewing machines available, the compound sewing machine stands out as a vital tool for both seasoned professionals and hobbyists alike. Its unique design and multifunctional capabilities make it an essential asset in any sewing workshop.

A compound sewing machine is distinguished by its ability to simultaneously perform multiple sewing operations. This multifaceted capability is largely due to its specially engineered walking foot mechanism that enables it to move both the upper and lower layers of fabric at an equal pace. This is particularly useful when working with thick or layered materials, as it ensures consistent stitching without any fabric slippage or misalignment.

One of the primary advantages of using a compound sewing machine is its flexibility in handling a wide range of textiles. From delicate silk to heavy upholstery fabric, these machines can adapt to various materials, making them suitable for diverse sewing projects. This adaptability is especially crucial for businesses that deal with multiple types of fabric in their production lines. With a compound sewing machine, users can switch between different fabric types without the need for extensive adjustments, thereby saving time and effort.

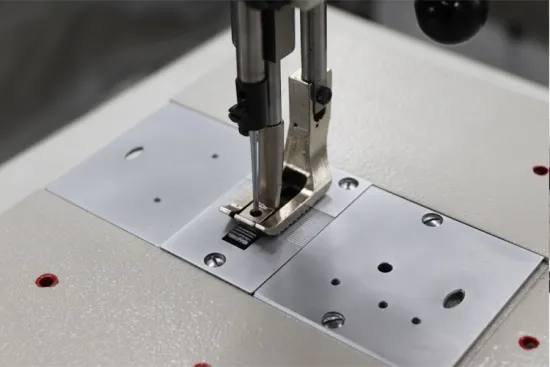

compound sewing machine

Additionally, compound sewing machines are designed to accommodate various sewing techniques, such as straight stitching, zigzag stitching, and even decorative sewing. This allows users to engage in a broader spectrum of creative projects, from creating intricate patterns on garments to assembling heavy-duty outdoor gear. The ability to combine different stitching styles within a single machine enhances creativity and efficiency, making it a favorite among fashion designers and craftspeople.

Maintenance and durability are also key aspects of compound sewing machines. Built with robust components, they are designed to withstand extensive use in industrial environments. Regular maintenance, including oiling and cleaning, can further enhance their lifespan, ensuring that they remain reliable tools for years to come. Businesses benefit from investing in compound sewing machines as they can manage production demands without frequent breakdowns or repairs.

For those just starting in the sewing world, a compound sewing machine may seem a daunting investment due to its advanced features. However, the learning curve is not steep, and many manufacturers offer comprehensive guides and tutorials to help new users master their machines. As users gain experience, they will find that the machine's capabilities far outweigh the initial challenges.

In conclusion, the compound sewing machine is a remarkable innovation that meets the diverse needs of modern sewing. With its ability to handle various fabrics and perform multiple stitching techniques, it is an invaluable asset for both commercial enterprises and individual crafters. As the sewing industry continues to evolve, compound sewing machines remain at the forefront, empowering creators to pursue their artistic visions with unparalleled ease and efficiency.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025