Guide to Choosing the Best Bag Sewing Machine for Your Crafting Needs

The Evolution and Significance of Bag Sewing Machines

In the world of manufacturing and craftsmanship, the bag sewing machine holds a vital role, especially in the production of bags for various purposes, including shopping, travel, and the industrial sector. As environmental awareness grows, the demand for reusable fabric bags increases, further emphasizing the importance of efficient bag sewing machines. This article explores the evolution, functionality, and significance of bag sewing machines in today's market.

Historical Context

The sewing machine, invented in the early 19th century, revolutionized the textile industry. However, the specific design for bag sewing machines came much later, as the need for durable and functional bags became evident. Initially, bags were sewn by hand, which was time-consuming and labor-intensive. The earliest bag sewing machines were adapted from general industrial sewing machines but tailored to the specific requirements of bag production, such as the need for heavier fabric and durable seams.

Types of Bag Sewing Machines

Today, there are various types of bag sewing machines designed to accommodate different materials and bag styles. Some of the most common types include

1. Flat Bed Sewing Machines These machines are ideal for sewing flat materials, making them suitable for producing simple, one-dimensional bags. They are widely used in industries that produce tote bags and grocery bags.

2. Walking Foot Machines Equipped with a special mechanism that allows the foot to walk the fabric through, these machines are perfect for sewing thicker materials like canvas or denim. They are essential in the production of heavy-duty bags used for tools or outdoor activities.

3. Heavy-Duty Sewing Machines Designed for the toughest sewing tasks, these machines can handle multiple layers of thick fabric and are commonly used in industrial settings. They are significant in crafting durable bags that can withstand wear and tear.

4. Computerized Bag Sewing Machines With advancements in technology, computerized sewing machines have entered the market, allowing for high precision and speed. These machines can be programmed for various patterns and techniques, increasing production efficiency for custom bag designs.

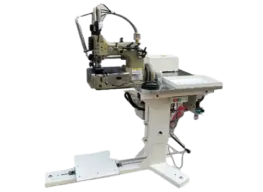

bag sewing machine

Key Features and Benefits

The functionality of bag sewing machines goes beyond mere stitching. Some key features include

- Heavy-Duty Needles and Threads These machines are equipped to handle strong threads and needles, enabling the production of robust seams that can endure significant stress.

- Speed and Efficiency Bag sewing machines are designed for high-speed operation, allowing manufacturers to produce large quantities in a short amount of time. This efficiency is crucial in meeting the growing demand for bags, especially in retail environments.

- Customization Options Many modern bag sewing machines allow for various stitching patterns, styles, and sizes, facilitating customization. This feature is particularly relevant as consumers increasingly seek unique and personalized products.

The Role in Sustainable Practices

As awareness of environmental issues rises, the demand for sustainable products, such as cloth shopping bags, is also increasing. Bag sewing machines play a critical role in this shift. By enabling the production of reusable bags, these machines contribute to reducing plastic waste and promoting eco-friendly practices.

Moreover, small businesses and local artisans can harness bag sewing machines to create custom bags made from organic or recycled materials. This not only provides consumers with eco-conscious choices but also stimulates local economies and craftsmanship.

Conclusion

The bag sewing machine is an essential tool in the textile industry, reflecting the evolution of manufacturing practices and responding to consumer needs. From traditional hand-sewing methods to advanced computerized technology, these machines have transformed how bags are produced. As society moves towards sustainable practices and the demand for reusable products grows, the significance of bag sewing machines will undoubtedly continue to rise, making them a cornerstone of modern manufacturing and a catalyst for positive environmental change. Whether for industrial production or artisanal craftsmanship, bag sewing machines exemplify the blend of functionality, efficiency, and sustainability that defines contemporary textile manufacturing.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025