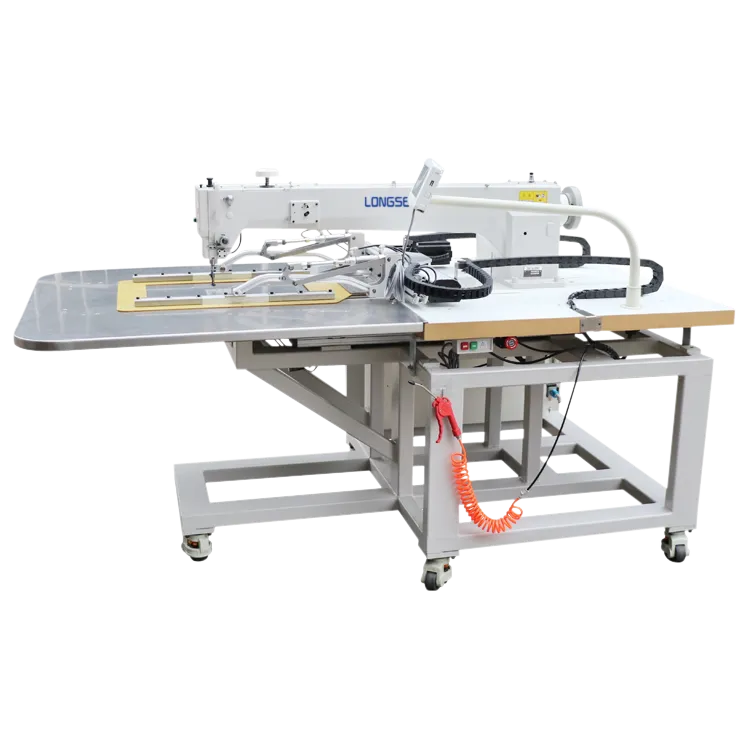

auto pattern sew

The Art and Science of Auto Pattern Sewing

In the world of fashion and textile design, auto pattern sewing has emerged as a remarkable fusion of technology and artistry. This innovative approach not only streamlines the sewing process but also adds a new dimension of creativity and precision to garment production. By leveraging computer-generated patterns, designers and manufacturers can create intricate designs that were once labor-intensive and time-consuming.

At its core, auto pattern sewing utilizes advanced software to generate patterns based on various parameters, such as fabric type, style, and desired measurements. This means that designers can experiment with a multitude of styles without the hassle of manual drafting. For instance, whether it’s a fitted dress, a flowing skirt, or a tailored suit, the software can produce accurate patterns that can be directly fed into automated cutting machines.

One of the most significant advantages of auto pattern sewing is its ability to enhance efficiency. Traditional sewing methods require significant manpower and time investment, often leading to inconsistencies and errors. However, with auto pattern systems, the precision significantly increases; patterns are cut with exact measurements, reducing fabric waste and ensuring better quality control. Manufacturers can produce garments faster, meeting the growing demand for quick turnarounds in the fashion industry.

auto pattern sew

Moreover, this technology enables customization like never before. Consumers today crave personalized clothing, and auto pattern sewing makes this feasible on a larger scale. From bespoke tailoring to exclusive designs, customers can choose specific patterns and measurements that cater to their unique preferences. This shift towards customization not only increases customer satisfaction but also fosters a deeper connection between the consumer and the brand.

The integration of auto pattern sewing also opens doors for sustainable fashion practices. By minimizing fabric waste through precise cutting and pattern design, brands can significantly reduce their environmental footprint. Additionally, the ability to create patterns on demand means that companies can maintain smaller inventories and produce only what is needed, further promoting sustainability.

As with any technological advancement, challenges do exist. Initial costs for implementing auto pattern sewing systems can be high, and there is a learning curve associated with training staff to use new software effectively. However, the long-term benefits of increased productivity, reduced waste, and the ability to innovate often outweigh these initial hurdles.

In conclusion, auto pattern sewing represents a revolutionary shift in how garments are designed and produced. By combining traditional craftsmanship with cutting-edge technology, the fashion industry is on the brink of a transformative era. Designers can explore new creative horizons, manufacturers can operate more efficiently, and consumers can enjoy a level of personalization that was previously unattainable. As this technology continues to evolve, it promises to reshape the future of fashion in exciting and sustainable ways.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025