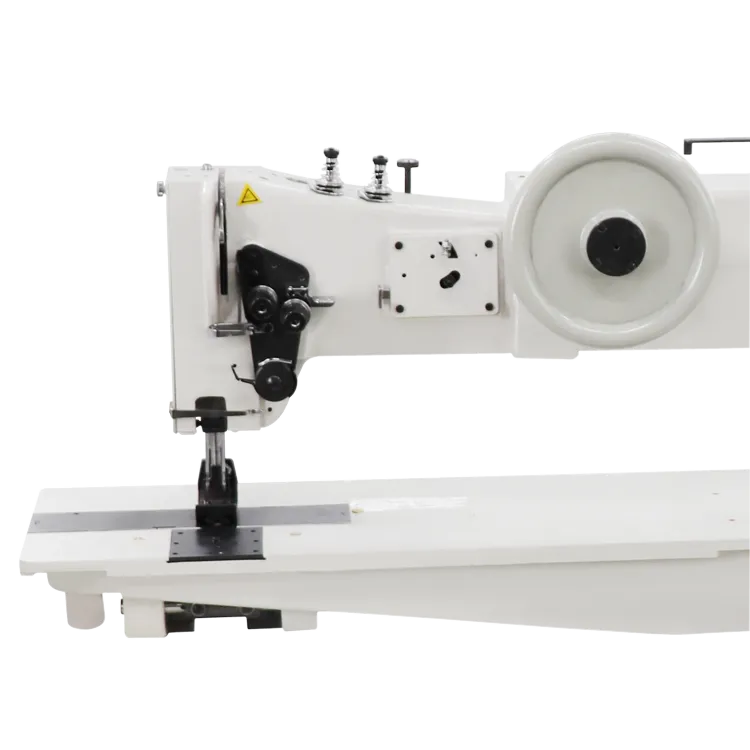

woven sack bag sewing machine

The Importance of Woven Sack Bag Sewing Machines in Modern Manufacturing

In recent years, the demand for woven sack bags has surged due to their versatility and ecological benefits. Industries ranging from agriculture to construction rely on these durable bags for the effective packaging and transport of goods. This growing demand has consequently led to the increased significance of woven sack bag sewing machines in modern manufacturing processes. Understanding these machines, their functions, and their impact on various sectors is essential for businesses aiming for efficiency and sustainability.

What are Woven Sack Bags?

Woven sack bags, often made from polypropylene or other synthetic fibers, are characterized by their strength and durability. These bags are designed for various applications, including the packaging of grains, seeds, fertilizers, chemicals, and other bulk products. The woven nature of these sacks allows for breathability, making them ideal for agricultural purposes. Moreover, unlike paper or plastic bags, woven sacks can be reused multiple times, aligning with the sustainability goals of many companies.

The Role of Woven Sack Bag Sewing Machines

Woven sack bag sewing machines play a pivotal role in the production of these bags. They are designed specifically to handle the sturdy materials used in woven sacks, ensuring that seams are strong and reliable. The sewing process is crucial as it determines the longevity and functionality of the bags.

These machines utilize heavy-duty stitching techniques to ensure that bags can withstand the rigors of transportation and storage. With advancements in technology, modern sewing machines can now automate much of the sewing process, enhancing speed and precision—features that are indispensable in high-volume production environments.

Advantages of Using Woven Sack Bag Sewing Machines

1. Enhanced Efficiency Automated woven sack bag sewing machines significantly increase production speed. Manual sewing can be time-consuming, leading to delays in fulfilling orders. Automation minimizes this downtime, allowing companies to meet market demands promptly.

woven sack bag sewing machine

2. Cost-Effectiveness While the initial investment in high-quality sewing machines may be substantial, the long-term savings are significant. Automated machines reduce the labor costs associated with manual sewing and minimize material waste through precise stitching.

3. Consistency and Quality Control One of the challenges in manual sewing is maintaining uniformity in stitching quality. Automated sewing machines provide consistency, which is crucial for businesses that need to adhere to specific quality standards. This reliability ensures that each bag produced meets the required specifications.

4. Versatility Modern woven sack bag sewing machines can accommodate different bag sizes and styles, allowing manufacturers to diversify their product offerings. This adaptability is essential in catering to various industries and customer needs.

Sustainability and Environmental Impact

In the era of heightened environmental awareness, the production of woven sack bags with sewing machines also supports sustainability initiatives. The durability of woven bags means they have a longer lifecycle compared to single-use plastic bags, reducing overall waste. Moreover, advancements in sewing technology have led to the development of machines that consume less energy, further minimizing the carbon footprint associated with manufacturing.

Conclusion

The importance of woven sack bag sewing machines in today’s manufacturing landscape cannot be overstated. As industries continue to recognize the benefits of woven sacks, the demand for efficient sewing solutions will only increase. Embracing technology in the sewing process not only enhances productivity and quality but also aligns with sustainable business practices.

Businesses invested in producing woven sack bags should consider upgrading their sewing machinery to meet the growing demands of the market while promoting environmental responsibility. In doing so, they not only improve their operational efficiency but also contribute positively to the world, paving the way for a greener and more sustainable future.

In summary, the integration of woven sack bag sewing machines into manufacturing processes reflects an important synergy between innovation and sustainability, showcasing how technology can enhance traditional practices for better commercial and ecological outcomes.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025