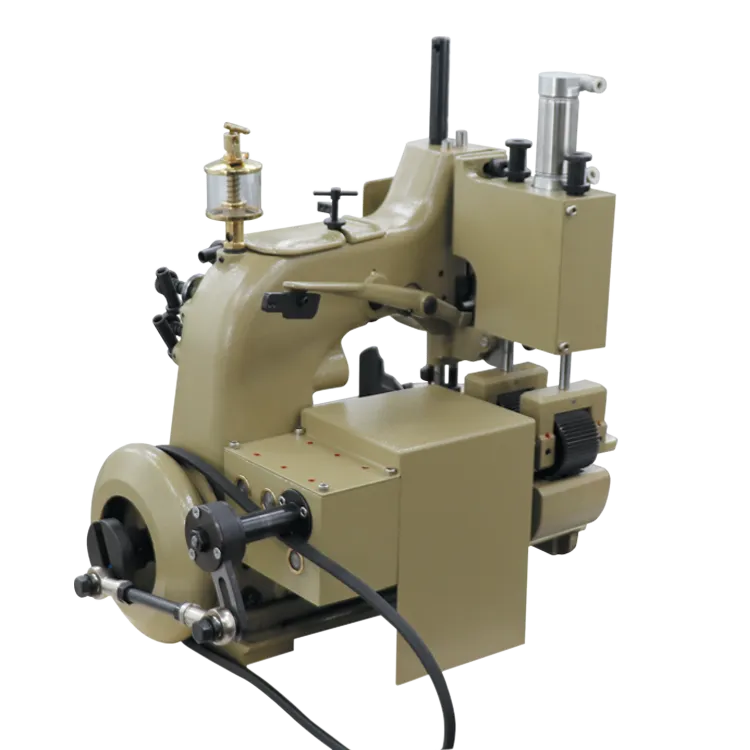

two needle industrial sewing machine

The Two Needle Industrial Sewing Machine A Comprehensive Overview

The two needle industrial sewing machine is a staple in the world of garment manufacturing, renowned for its efficiency and versatility. This machine employs two needles that can operate independently or in synchronization, allowing for a variety of stitch types that cater to diverse sewing needs. With its advanced features and capabilities, it is an indispensable tool for textile production, ensuring high-quality seams that enhance durability and aesthetics.

One of the primary advantages of the two needle industrial sewing machine is its ability to produce parallel seams. This feature is particularly useful in industries where strength and flexibility are paramount, such as in the production of jeans, outerwear, and other heavy-duty garments. The dual needles create a robust line of stitching that can withstand significant stress, making it ideal for items subjected to heavy wear and tear.

Moreover, this type of sewing machine allows for the use of different threads, which can be beneficial for decorative purposes. For instance, manufacturers may choose to employ contrasting thread colors to create visual interest in their products. The ability to execute multiple stitch patterns – such as topstitching, double-stitched seams, and decorative stitches – provides designers with endless possibilities to enhance the aesthetic appeal of their garments.

In addition to its functional benefits, the two needle machine significantly increases productivity. Unlike single needle machines, which require additional passes for certain types of stitching, the two needle machine can accomplish tasks in a single operation. This is critical in a fast-paced production environment where time efficiency directly translates to cost savings and the ability to meet tight deadlines.

two needle industrial sewing machine

Furthermore, modern two needle industrial sewing machines come equipped with various advanced features. Many machines offer automatic thread trimming, programmable stitch patterns, and adjustable sewing speeds. These technological enhancements not only expedite the sewing process but also reduce the likelihood of errors, ensuring a high standard of quality control.

The use of a two needle industrial sewing machine is not limited to clothing manufacturing. Its applications extend to a wide range of industries, including upholstery, automotive interiors, and outdoor gear production. By catering to different materials, such as leather, synthetic fabrics, and heavy textiles, this machine proves to be a versatile choice for many sectors within the manufacturing landscape.

Training operators to effectively use a two needle industrial sewing machine is paramount for maximizing its potential. Proper training ensures that workers can navigate its functionalities and troubleshoot common issues, thereby optimizing performance and mitigating downtime. Investing in skill development for employees can lead to improved production quality and efficiency.

In conclusion, the two needle industrial sewing machine stands as a vital asset in the textile industry. Its ability to produce strong, parallel seams, coupled with the potential for decorative stitching, makes it highly sought after for garment production. With advancements in technology further enhancing its capabilities, the two needle machine is set to remain an essential tool for manufacturers aiming to deliver high-quality, fashionable products efficiently. Whether in clothing production or other applications, this machine continues to shape the landscape of industrial sewing, meeting the demands of an ever-evolving market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025