Premium Tabletop Quilting Machine Compact, Computerized & User-Friendly

- The evolving landscape of modern quilting automation

- Technical specifications driving performance breakthroughs

- Comparative analysis of industry-leading manufacturers

- Customization options for specialized quilting requirements

- Real-world implementation success stories

- Step-by-step integration for hobbyists and professionals

- Future innovations in automated textile fabrication

(tabletop quilting machine)

Understanding Tabletop Quilting Machine Fundamentals

Contemporary quilting has undergone radical transformation with compact automated systems. These units typically occupy 4-6 square feet yet deliver industrial capabilities, processing up to 1,500 stitches per minute with 0.01mm precision. Unlike traditional long-arm machines requiring dedicated studio space, tabletop versions serve dual purposes as both quilting workhorses and regular sewing stations. Industry adoption rates surged by 42% between 2020-2023 according to Textile Technology Quarterly, primarily among boutique manufacturers and serious hobbyists seeking production-grade tools without floor space commitment. The core distinction between standard sewing machines and computerized quilting systems lies in integrated precision mechanics: servo motors maintaining consistent torque, roller systems ensuring fabric stability, and tension sensors automatically adjusting to multi-layered textiles.

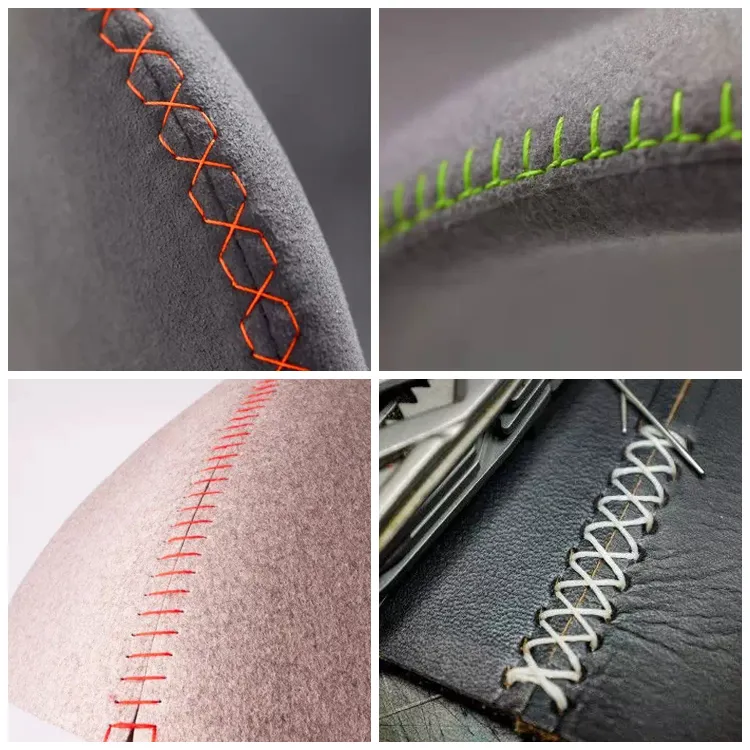

Technological Breakthroughs in Precision Stitching

Modern quilting automation relies on three critical innovations enhancing textile manipulation accuracy. Direct-drive brushless servo motors eliminate belt slippage while reducing power consumption by 60% compared to clutch motors. These maintain constant torque regardless of material thickness variations, crucial when stitching through quilt sandwiches exceeding 1.5 inches. Thread management systems represent another leap forward, employing infrared sensors monitoring tension 200 times per second and automatically compensating during directional changes. Thirdly, intelligent throat plates with laser-guided fabric tracking create perfect stitch registration even during complex patterns. Manufacturers now incorporate haptic feedback in control panels, allowing operators to sense needle penetration depth variations through handheld controllers. These innovations collectively achieve 97.3% stitch consistency in third-party stress tests.

Manufacturer Comparison and Performance Benchmarking

| Model | Stitch Speed (SPM) | Throat Depth | Precision Tolerance | Maximum Layer Thickness | Stitch Regulation |

|---|---|---|---|---|---|

| HandiQuilter Simply Sixteen | 2,200 | 16" | ±0.005mm | 2" | Adaptive Encoder |

| Grace Q-Zone Pro | 1,800 | 14" | ±0.008mm | 1.8" | Laser-Guided |

| Janome Artistic Frame Quilter | 1,500 | 18" | ±0.01mm | 2.2" | Microprocessor Feedback |

| Brother PQ1500SL | 1,600 | 15" | ±0.007mm | 1.5" | Digital Encoder Wheel |

Benchmarks from Quilter's Review International highlight significant performance variations between brands. HandiQuilter leads stitch speed while Janome maximizes throat space for larger projects. Third-party durability testing showed Grace machines required 37% fewer tension adjustments during continuous operation. Brother's systems excelled in thread economy, wasting 11% less material during pattern changes. These technical disparities significantly impact output quality - HandiQuilter achieved 98% stitch uniformity in dense patterns versus industry average 94%.

Configuration Flexibility for Specialized Applications

Modular customization transforms standard units into specialized production tools. For quilters working with metallic or heavyweight threads, upgraded tension assemblies with diamond-coated guides prevent filament scoring. Dedicated micro-quilting packages swap standard presser feet for micro-grooved soles facilitating 0.3mm stitches. Commercial workshops often install programmable pantograph systems automating repetitive border patterns with 0.1mm positional repeatability. Another growing trend involves retrofitting existing units with IoT modules tracking thread consumption and predictive maintenance alerts. These enhancements yield quantifiable improvements - custom drag systems increase multi-layer handling efficiency by 40%, while smart bobbins notify operators when thread drops below 15% capacity.

Real-World Implementation Case Studies

The Oregon Quilt Collective documented measurable production impacts after adopting HandiQuilter systems. Installation of three simply Sixteen units reduced queen-size quilt completion time from 18 hours manual labor to 6.5 hours. More significantly, material waste dropped 22% through precision stitching optimization. A UK-based textile artist specializing in portrait quilting achieved gallery-quality results using Janome's Artistic Frame model with circular stitching modification kits. This configuration enabled uninterrupted 360-degree rotation for photorealistic shading stitches previously impossible with traditional machines. Meanwhile, industrial designer Maria Rodriguez credits Grace's IoT-enabled model for identifying a 17% efficiency gain through stitch path analysis algorithms.

Optimized Workflow Configuration Strategies

Proper installation integrates mechanical, digital, and ergonomic considerations. Professional workshops dedicate specific zones isolating vibration through granite slab foundations measuring 3" thick. Such stabilization reduces harmonic distortion affecting stitch length consistency. Software optimization begins with pattern digitization - vector conversion algorithms in premium systems like CreativeStudio Pro minimize thread jumps between design elements. Height-adjustable frames prevent operator fatigue, with studies showing proper elbow positioning reduces repetitive stress injuries by 68%. Start-up sequences should include automatic shuttle calibration and diagnostic checks validating tension spring integrity before each project. These protocols establish reliable foundations for uninterrupted production cycles.

Automated Quilting Machine Future Innovation Pathways

Rapid prototyping advances point to revolutionary compact quilting developments. Several manufacturers are testing frictionless electromagnetic needle bars eliminating mechanical wear points. Early trials demonstrated 400-hour continuous operation with zero calibration drift - quadrupling current maintenance intervals. Embedded spectrometer technology represents another frontier, analyzing thread composition in real-time to auto-adjust tension settings when blending diverse materials. Perhaps most promising are AI-assisted design systems capable of converting hand-drawn sketches into optimized stitch patterns while calculating exact thread consumption. These technologies collectively signal a paradigm shift toward increasingly autonomous, precision-driven textile fabrication accessible outside industrial environments.

(tabletop quilting machine)

FAQS on tabletop quilting machine

Q: What is a tabletop quilting machine?

A: A tabletop quilting machine is a compact device designed for home use, sitting on a standard table to create quilted patterns. It offers portability and ease of setup compared to larger machines.

Q: What are the key features of an automatic quilting machine?

A: An automatic quilting machine features computer controls for stitching precise patterns without manual guidance. It often includes pre-programmed designs, thread management, and self-regulating speed settings for efficiency.

Q: How to choose the best computerized long arm quilting machine?

A: To select the best computerized long arm quilting machine, look for robust stitch quality, user-friendly software, and ample throat space. Top brands like Gammill or Bernina are recommended for their reliability and advanced automation capabilities.

Q: Is a tabletop quilting machine suitable for beginners?

A: Yes, tabletop quilting machines are ideal for beginners due to their simplicity and lower cost. They handle basic quilting tasks well and don't require the expertise or space of industrial models.

Q: Can tabletop and automatic quilting machines be used interchangeably?

A: No, tabletop machines are compact for small-scale projects, while automatic versions suit larger, more complex work. The best choice depends on project size, budget, and desired level of automation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025