pp woven bag cutting sewing printing line machine

The PP Woven Bag Cutting, Sewing, and Printing Line Machine A Comprehensive Overview

In the rapidly evolving world of packaging solutions, the demand for high-quality, durable, and cost-effective materials continues to rise. Polypropylene (PP) woven bags have gained immense popularity due to their strength, resistance to moisture, and versatility in various applications. To meet this demand, manufacturers have increasingly turned to specialized equipment designed for the efficient cutting, sewing, and printing of PP woven bags. This article delves into the features, specifications, and significance of the PP woven bag cutting, sewing, and printing line machine.

Understanding PP Woven Bags

PP woven bags are made from polypropylene, a thermoplastic polymer that offers remarkable durability and resistance to environmental factors. These bags are commonly used for packaging agricultural products, construction materials, chemicals, and food items. The growing preference for these bags has necessitated a streamlined production process to ensure quality and efficiency. This is where the cutting, sewing, and printing line machine comes into play.

The Cutting Process

The initial stage of the production line involves cutting large rolls of PP fabric into specific dimensions suitable for bag production. The cutting process must be precise to prevent material waste and ensure uniformity in the size of the bags. Advanced cutting machines are equipped with automated features that enhance precision and efficiency. They use high-speed cutting blades and laser technology, which significantly reduce the time it takes to prepare the materials for sewing. By adopting modern cutting techniques, manufacturers can enhance productivity and maintain quality standards.

The Sewing Process

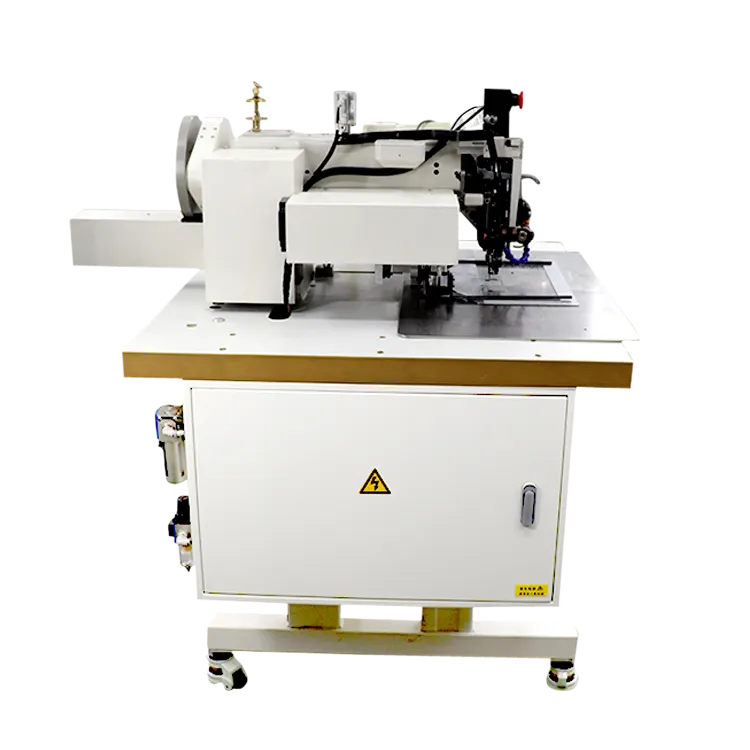

Once the PP fabric is cut into shape, the next phase involves sewing the pieces together to form bags. This step requires high-quality industrial sewing machines that can handle the thickness and strength of woven polypropylene fabric. These machines are designed for high-speed operation, allowing manufacturers to produce a large number of bags in a short period. Furthermore, the sewing process is crucial for ensuring that the bags are durable and can withstand the weight of the materials they are designed to carry.

pp woven bag cutting sewing printing line machine

The sewing machines in this production line typically come with advanced features such as automatic thread trimming, adjustable sewing speeds, and the ability to perform multiple stitch patterns. This versatility enables manufacturers to customize bags according to their clients' specifications. Additionally, efficient sewing mechanisms help reduce production costs and increase overall profitability.

The Printing Process

In today's market, branding plays a crucial role in product recognition and sales. Consequently, the printing of logos and designs on PP woven bags has gained significant importance. The cutting, sewing, and printing line machine integrates advanced printing technology that can accurately reproduce high-quality images and graphics onto the bags.

Digital printing and flexographic printing are two popular methods utilized in this process. Digital printing allows for high-resolution designs with vibrant colors, while flexographic printing is ideal for bulk production with consistent quality. Both methods can be easily adjusted to meet different printing requirements, enabling manufacturers to offer customized solutions for their clients.

Conclusion

The PP woven bag cutting, sewing, and printing line machine represents a critical investment for manufacturers in the packaging industry. By automating these processes, companies can achieve greater efficiency, reduce operational costs, and improve the overall quality of their products. Moreover, the ability to print custom designs on bags not only enhances brand visibility but also caters to the specific needs of various industries.

As businesses continue to seek innovative solutions to meet market demands, the role of advanced machinery in the production of PP woven bags will remain vital. The cutting, sewing, and printing line machine provides a comprehensive approach to manufacturing that aligns with the principles of efficiency, quality, and customization, making it an essential tool in the contemporary packaging landscape. As demand for sustainable and recyclable packaging options grows, investing in such technology will not only ensure profitability but also contribute to environmentally responsible practices in the packaging industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025