Şub . 15, 2025 05:10

Back to list

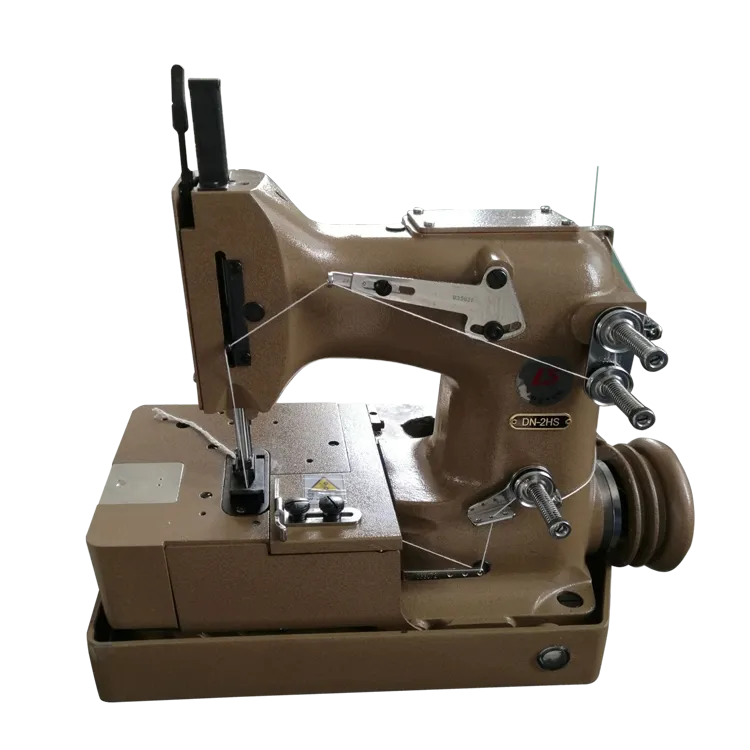

jumbo bag stitching machine

Investing in a PP bag stitching machine can be a game-changer for manufacturers involved in packaging goods. Understanding the intricacies of pricing can guide buyers in making informed decisions. This exploration combines firsthand experiences, expertise, authoritative insights, and reliable data to provide a comprehensive understanding of the pricing dynamics of PP bag stitching machines.

From a buyer’s perspective, understanding the market landscape is crucial. Engaging with industry forums and customer reviews can provide insights into the performance and long-term reliability of various models and brands. Networking with industry professionals offers opportunities to discuss experiences and recommendations, helping in gauging the true value of a machine beyond its price. The expertise of the team operating the machine also plays a role in maximizing return on investment. Well-trained personnel can exploit the machine’s full potential, thus justifying higher upfront costs with improved efficiency and reduced error rates during production. Authoritative resources suggest that seeking machines with robust after-sales support and warranty options can be advantageous. Such offerings provide peace of mind and ensure continuity in production, minimizing downtime due to mechanical failures. Trustworthiness in the purchasing process can be enhanced by dealing with certified dealers and requesting demonstrations or trials before purchase. Transparent dealings usually indicate a dealer’s confidence in the product, increasing the buyer's confidence as well. In conclusion, while the initial cost of a PP bag stitching machine may seem substantial, factoring in elements such as quality, technological advantages, after-sales support, and operator expertise can significantly influence the decision-making process. Striking a balance between budget and machine functionality is key, with long-term benefits often outweighing immediate savings. By approaching the purchase with informed insights and strategic planning, businesses can secure a machine that not only meets their current needs but also supports future growth.

From a buyer’s perspective, understanding the market landscape is crucial. Engaging with industry forums and customer reviews can provide insights into the performance and long-term reliability of various models and brands. Networking with industry professionals offers opportunities to discuss experiences and recommendations, helping in gauging the true value of a machine beyond its price. The expertise of the team operating the machine also plays a role in maximizing return on investment. Well-trained personnel can exploit the machine’s full potential, thus justifying higher upfront costs with improved efficiency and reduced error rates during production. Authoritative resources suggest that seeking machines with robust after-sales support and warranty options can be advantageous. Such offerings provide peace of mind and ensure continuity in production, minimizing downtime due to mechanical failures. Trustworthiness in the purchasing process can be enhanced by dealing with certified dealers and requesting demonstrations or trials before purchase. Transparent dealings usually indicate a dealer’s confidence in the product, increasing the buyer's confidence as well. In conclusion, while the initial cost of a PP bag stitching machine may seem substantial, factoring in elements such as quality, technological advantages, after-sales support, and operator expertise can significantly influence the decision-making process. Striking a balance between budget and machine functionality is key, with long-term benefits often outweighing immediate savings. By approaching the purchase with informed insights and strategic planning, businesses can secure a machine that not only meets their current needs but also supports future growth.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025