PP Bag Sewing Machine for Efficient Production and Seamless Operation in Manufacturing

The Evolution and Importance of the PP Bag Sewing Machine

In the modern manufacturing landscape, the demand for durable and reliable packaging solutions has skyrocketed. One of the most significant advancements in this realm has been the development of the PP (Polypropylene) bag sewing machine. These machines have revolutionized the way industries package their goods, offering a blend of efficiency, versatility, and economic viability.

Understanding PP Bags

Polypropylene bags are widely used due to their strength, lightweight nature, and resistance to moisture and chemicals. These bags are commonly employed in various industries, including agriculture, construction, and food packaging. The versatility of polypropylene bags makes them ideal for transporting both bulk and individual items, thus meeting diverse consumer needs. With the rise in demand for PP bags, sewing machines specifically designed for this purpose have become invaluable.

The Role of PP Bag Sewing Machines

PP bag sewing machines are engineered to sew multiple layers of polypropylene fabric, creating strong, reliable seams that ensure the contents remain secure. These machines come equipped with specialized features that enhance their functionality. For instance, many modern machines utilize high-speed sewing technology that allows for quick production rates, essential for meeting the demands of high-volume manufacturing.

Moreover, these sewing machines are designed to be user-friendly, often featuring automatic thread tension adjustment and programmable stitch lengths. Such innovations not only improve the quality of the stitching but also reduce the risk of operator error, making it easier for businesses to train new employees.

Benefits of Using PP Bag Sewing Machines

1. Efficiency One of the most significant advantages of PP bag sewing machines is their efficiency. These machines can operate at high speeds, significantly reducing production time. This efficiency is particularly beneficial for companies that require large quantities of bags in a short timeframe, allowing them to meet their production targets without compromising on quality.

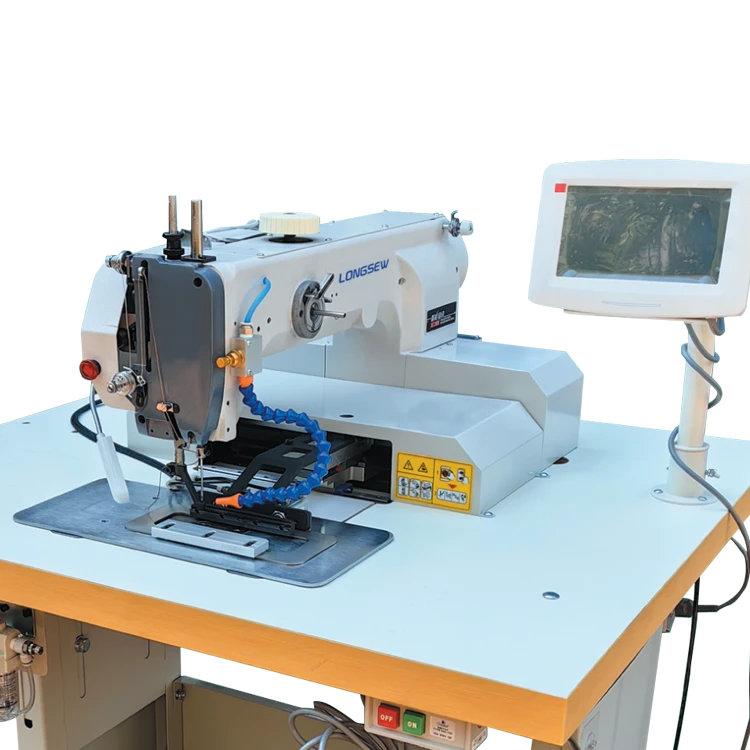

pp bag sewing machine

2. Cost-effectiveness Although the initial investment in a sewing machine might be substantial, the long-term savings can be significant. By streamlining the production process and reducing labor costs, businesses can increase their profit margins. Additionally, the durability of the resulting bags can reduce waste and the need for frequent replacements.

3. Quality and Consistency Manual sewing can lead to inconsistencies in seam quality, which can compromise the integrity of the bag. In contrast, PP bag sewing machines provide uniformity in stitching, resulting in stronger seams and a more professional finish. This consistency is crucial for maintaining brand reputation and ensuring customer satisfaction.

4. Versatility Many sewing machines are equipped with adjustable settings that allow them to handle different bag sizes and styles. This versatility can help manufacturers cater to various market needs, whether they are producing standard bags for bulk commodities or customized designs for retail products.

The Future of PP Bag Sewing Machines

As the global market evolves, the demand for sustainable solutions continues to rise. In response, manufacturers are increasingly looking into eco-friendly alternatives to traditional polypropylene. This shift may influence the design and functionality of future PP bag sewing machines, introducing features such as biodegradable stitching or materials that minimize environmental impact.

Furthermore, advancements in automation and smart technology are poised to enhance the capabilities of these machines. For example, integrating AI-driven systems could enable real-time monitoring and quality control, further increasing production efficiency and the overall quality of the finished products.

Conclusion

PP bag sewing machines play a vital role in the packaging industry, offering a combination of efficiency, quality, and cost-effectiveness. As industries continue to evolve and adapt to new challenges, these machines will undoubtedly remain at the forefront of innovation, ensuring that businesses can meet consumer demands today and in the future. Embracing the latest technology and trends in machine design will be essential for manufacturers aiming to maintain a competitive edge in a rapidly changing market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025