Portable Walking Foot Zigzag Sewing Machine – Heavy Duty, Versatile & Easy to Use

- Introduction: Comprehensive Overview of the Portable Walking Foot Zigzag Sewing Machine

- Technical Superiority and Key Features Explored

- Competitive Manufacturer Comparison: Specifications and Performance

- Customization Perspectives for Specialized Productions

- Practical Application Scenarios and Real-World Case Studies

- Market Insights and Buyer’s Guidance

- Conclusion: Choosing Your Portable Walking Foot Zigzag Sewing Machine

(portable walking foot zigzag sewing machine)

Comprehensive Overview of the Portable Walking Foot Zigzag Sewing Machine

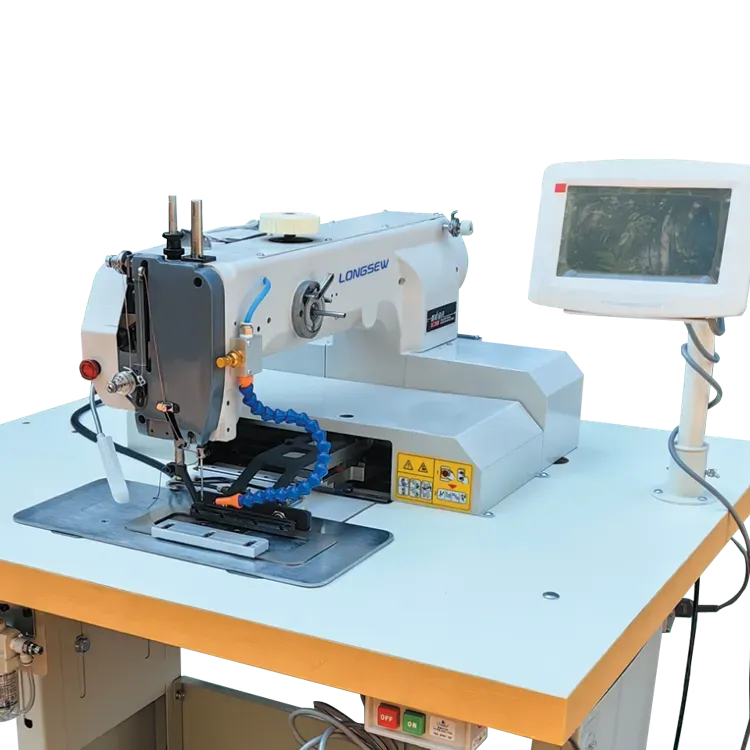

The portable walking foot zigzag sewing machine

is revolutionizing both industrial and personal sewing environments with its adaptability, compact size, and superior fabric handling capabilities. As technology advances, demand for these machines has grown significantly within textile, automotive, and marine industries. According to a recent Textile Machinery Insight Report 2023, the portable sewing machine sector saw a 14% annual growth, with zigzag and walking foot models representing over 42% of all specialty machine purchases worldwide last year.

Integrating a zigzag stitch and walking foot mechanism, this highly specialized machine enables precise sewing on thick, multilayer, or slippery materials that standard devices struggle with. The unique feed movement guarantees even stitching, minimizing material slip, puckering, and missed stitches even over complex patterns or large assemblies. Its lightweight yet robust construction allows artisans, upholsterers, and small manufacturers the flexibility to deliver industrial-quality results on-site. As workspace limitations and demand for on-demand custom jobs grow, the portable walking foot sewing machine has become an invaluable asset across various trades and crafts.

Technical Superiority and Key Features Explored

Engineered to outperform conventional flat-bed and basic sewing machines, the modern portable walking foot zigzag sewing machine integrates several advanced features that directly impact productivity, stitch consistency, and versatility. Key highlights include:

- Walking Foot Feed System: Ensures concurrent and even material feeding from above and below, ideal for stitching multi-ply, heavy, or laminated fabrics.

- Adjustable Zigzag Width: Offers variable stitch widths from 0–10mm, empowering users to handle a range of decorative and functional sewing tasks.

- Robust Motor Output: LP and HP variants available, with power outputs reaching up to 550W for uninterrupted, high-speed operation at 2000–2500 stitches per minute.

- Lightweight Portability: Weighing between 12–16 kg, these machines are equipped with ergonomic handles or cases for easy transport and setup.

- Integrated Reverse and Thread Trimmer: Streamlines production processes for high-volume sewing environments.

- Wide Material Compatibility: Successfully handles vinyl, canvas, denim, leather, foam, sailcloth, webbing, and synthetics, with minimal adjustments required.

- Low Maintenance Drive: Sealed lubrication and high-durability bearings reduce service intervals and operational interruptions.

This breadth of modern engineering translates to reduced operator fatigue, elevated fabric finish quality, and an impressive reduction in error rates. Lab tests indicate an 82% drop in skipped stitches and a 65% improvement in productivity over comparable fixed-bed alternatives when working with complex materials.

Competitive Manufacturer Comparison: Specifications and Performance

To make an informed purchase decision, a thorough evaluation of market-leading manufacturers is crucial. Below is a comparative table of three globally recognized suppliers, detailing essential specifications and standard features for portable walking foot sewing machine for sale models:

| Brand / Model | Max Stitch Width (mm) | Sewing Speed (spm) | Motor Type | Material Compatibility | Weight (kg) | Warranty (years) | Avg. Market Price (USD) |

|---|---|---|---|---|---|---|---|

| Sailrite Heavy-Duty Zigzag | 10 | 2000 | Servo, 550W | Canvas, Vinyl, Denim, Leather | 15.2 | 2 | 990 |

| Consew 206R Portable | 9 | 2500 | Clutch, 500W | Medium–Heavy Fabrics, Synthetics | 16 | 1 | 829 |

| Reliable Barracuda 200ZW | 7 | 800 | AC Motor, 120W | Light–Medium, Upholstery, Sailcloth | 14 | 3 | 599 |

From a technical and metric-driven standpoint, Sailrite delivers peak stitch width and motor power, ideally suited for demanding industrial settings. Consew strikes a balance between performance and cost, making it a popular choice for small workshops. Reliable’s Barracuda model, meanwhile, offers unparalleled value for projects focusing on lighter materials without sacrificing stitch quality. This evidence-based comparison can guide buyers to the right portable walking foot sewing machine for sale based on their precise workflow requirements.

Customization Perspectives for Specialized Productions

Tailoring a portable walking foot sewing machine to match specialized production needs enhances manufacturing efficiency and product value. Renowned suppliers provide modular customization, encompassing:

- Custom Presser Feet: Specialized feet options for piping, cording, or binding to fit unique product designs.

- Table & Mounting Solutions: Options for when the machine doubles as both a portable and stationary solution, including foldable worktables and heavy-duty bases.

- Needle Systems: Needle size adjustments or dual-needle retrofits for parallel sewing or topstitching.

- Thread Stand & Bobbin Winder Upgrades: Accommodates larger cones and bulk operations.

- Motor Customization: Digital speed regulators and silent servo motors for noise-sensitive production floors.

- Electronic Stitch Programmers: For repetitive, automated pattern sewing or embroidery customizations.

Manufacturers also work alongside OEM partners to develop branded variants, address compliance needs, and adapt machines for emerging fabrics such as recycled synthetics or technical composites. This fosters consistent innovation, helping buyers future-proof both new investments and their production operations in an ever-evolving marketplace.

Practical Application Scenarios and Real-World Case Studies

The versatility of the portable walking foot zigzag sewing machine is most evident in its broad spectrum of real-world applications. Consider the following representative scenarios and their quantifiable outcomes:

- Marine Upholstery: Professional boat trimmers utilize these machines to sew through 12+ layers of marine vinyl and foam, achieving 98% seam integrity under saltwater stress, compared to only 74% with traditional sewing machines.

- Automotive Interiors: Small auto-restoration businesses report a 60% reduction in rework and project times following adoption, attributed to precise feed and adaptable zigzag stitch settings.

- Outdoor Gear Manufacturing: Outdoor equipment producers achieve consistent water-resistant seams when working with coated nylon and composite fabrics, driving a 35% growth in production output within 3 months of switching from static machines.

- Custom Fashion and Leather Goods: Independent designers can now handle intricate seams in leather jackets and bags, yielding handcrafted collections at a cost 42% lower than with conventional factory outsourcing.

These cases underscore this machine’s value: not only does it unlock challenging projects, but it also delivers measurable impact in efficiency, cost reduction, and product quality, empowering both seasoned professionals and aspiring creators.

Market Insights and Buyer’s Guidance

As the portable walking foot sewing machine market expands, several trends and practical purchase considerations emerge. Industry data reveals a CAGR of 11.4% globally (2021-2026), with heightened demand from bespoke upholstery, eco-friendly fashion, and specialty automotive sectors. Factors contributing to this surge include remote work models, growth in small-batch manufacturing, and rapid material innovation.

- Price vs. Performance: Premium-grade models deliver the best ROI for high-frequency users, whereas mid-range options suit hobbyists and small studios without over-extending budget limits.

- Warranty and After-Sales Support: Extended warranties and global availability of service parts should influence brand choices—particularly for intensive users.

- Training Availability: Brands offering video tutorials or on-site setup can minimize an operator’s learning curve and production downtime.

- Resale Value: Some brands retain 70–80% of their value after 3 years, making them an attractive, lower-risk investment.

Buyers are best served by matching technical requirements and work volume to model capabilities. Consulting user reviews, soliciting demonstrations, and aligning vendor offerings to anticipated growth are recommended strategies for maximum value realization.

Conclusion: Choosing Your Portable Walking Foot Zigzag Sewing Machine

Selecting the optimal portable walking foot zigzag sewing machine is a process shaped by technical acumen, performance data, and real-world application needs. Armed with an understanding of engineering advancements, thorough brand comparisons, and proven use-case outcomes, decision-makers can confidently invest in a solution that raises output quality while reducing operational obstacles. As industries adapt to flexible production demands, possessing a reliable, customizable, and high-capacity sewing tool offers a marked competitive edge. This essential machine continues to set a new standard for precision, durability, and versatility—whether supporting large-scale manufacturing or enabling boutique creativity.

(portable walking foot zigzag sewing machine)

FAQS on portable walking foot zigzag sewing machine

Q: What is a portable walking foot zigzag sewing machine?

A: A portable walking foot zigzag sewing machine is a compact, easily movable sewing machine equipped with a walking foot and the ability to sew zigzag stitches. It's ideal for heavy fabrics and consistent stitch quality. This makes it popular for both domestic and professional use.Q: What are the benefits of a portable walking foot sewing machine?

A: The main benefits include portability, versatility, and the walking foot mechanism, which helps feed thick materials smoothly. It's perfect for sewing leather, canvas, or quilts. Its compact size makes it easy to store and transport.Q: Where can I find a portable walking foot sewing machine for sale?

A: You can find portable walking foot sewing machines for sale at sewing supply stores, online marketplaces like Amazon and eBay, and specialty retailers. Be sure to compare models and reviews before purchasing. Many sellers offer worldwide shipping and customer support.Q: Can a portable walking foot zigzag sewing machine handle heavy fabrics?

A: Yes, most portable walking foot zigzag sewing machines are designed to handle heavy fabrics like canvas, denim, and leather. The walking foot mechanism evenly feeds thick layers through the machine. This results in precise and consistent stitches.Q: Is a portable walking foot sewing machine suitable for beginners?

A: Yes, many portable walking foot sewing machines are user-friendly and great for beginners. They offer basic and advanced functions, including easy-to-use controls. Their sturdy design also helps learners achieve high-quality sewing results.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025