Leather Sewing Machine Feet for Precision Wheel Stitching and Crafting

The Versatility of Leather Wheel Sewing Machine Foot

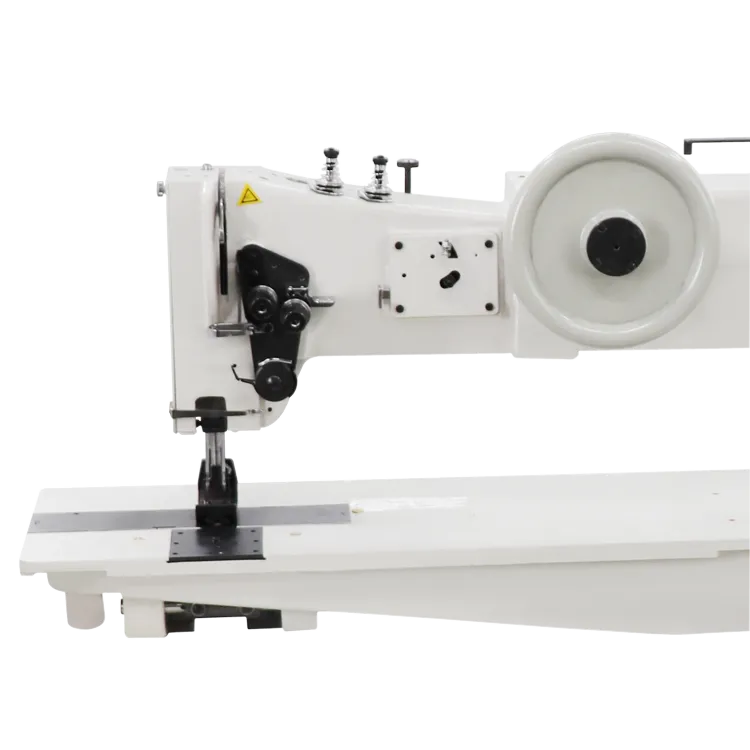

When it comes to sewing leather, choosing the right machine and foot is crucial for achieving professional results. One essential tool in this process is the leather wheel sewing machine foot. This specialized foot is designed to handle the unique challenges posed by leather, making it an invaluable accessory for both amateur and professional leatherworkers.

Leather, with its thickness and texture, requires specific techniques and tools to ensure seamless stitching. The leather wheel sewing machine foot, often referred to as a roller foot, features a set of small wheels that glide effortlessly over the material. This design minimizes friction and prevents the leather from slipping or bunching, which can occur with traditional presser feet. The wheels allow the foot to move smoothly, facilitating even pressure and consistent stitch quality.

One of the key advantages of using a leather wheel sewing machine foot is its ability to handle various types of leather, from soft lambskin to more rigid vegetable-tanned leather. As each type of leather has its own set of characteristics, the roller foot’s adaptability becomes a significant benefit. It can work effectively with multiple layers of leather, making it an excellent choice for projects such as bags, wallets, and belts that require reinforced seams.

In addition to functionality, the leather wheel sewing machine foot also promotes creativity. With this foot, leatherworkers can experiment with different stitch patterns and techniques without the fear of damaging their fabric. Whether working on decorative stitching or functional seams, the versatility of the roller foot allows for greater artistic expression.

leather wheel sewing machine foot

Installation of the leather wheel foot is straightforward, as it is compatible with many standard sewing machines. Once attached, users can adjust the stitch length and tension to suit their specific project requirements. This ease of use encourages both beginners and experienced sewers to take on leather projects with confidence.

Maintaining the leather wheel sewing machine foot is essential for ensuring optimal performance. Regular cleaning is recommended to remove any accumulated debris or adhesive that can affect the movement of the wheels. Additionally, ensuring that the foot is properly lubricated will help maintain its efficiency over time, contributing to a smoother sewing experience.

Furthermore, the leather wheel sewing machine foot supports a wide range of sewing techniques, including straight stitching, zigzag stitching, and edge stitching. This broad capability means users can complete a variety of leather projects without needing to switch out their presser feet constantly, saving both time and effort.

In conclusion, the leather wheel sewing machine foot is an indispensable tool for anyone working with leather. Its design minimizes friction, enhances mobility, and provides exceptional stitching quality, making it perfect for both beginners and seasoned professionals. By incorporating this tool into their sewing toolkit, leatherworkers can expand their creative horizons and achieve beautiful, professional-looking results in their projects. Whether crafting leather goods as a hobby or as part of a business, investing in a leather wheel sewing machine foot is a decision that pays off with every stitch.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025