Exploring the Features of Industrial Lockstitch Sewing Machines for Efficient Production

The Industrial Lockstitch Machine A Cornerstone of Modern Textile Manufacturing

The industrial lockstitch machine stands as a quintessential piece of equipment in the realm of textile manufacturing, embodying both efficiency and precision. This sewing machine, famed for its ability to produce a strong and durable stitch, has become an indispensable tool in the garment industry, supporting the mass production of clothing and textiles.

Historical Context

The origins of the lockstitch machine can be traced back to the mid-19th century, when the invention of the sewing machine revolutionized the textile industry. Before the advent of mechanical sewing, stitching was primarily done by hand, a process that was labor-intensive and time-consuming. The introduction of the lockstitch mechanism, attributed to figures like Elias Howe and Isaac Merritt Singer, marked a significant evolution in sewing technology. The design allowed for two threads to interlock, creating a more secure and uniform stitch compared to earlier machines that used chain stitches.

How It Works

The lockstitch machine operates on a simple yet effective principle. It utilizes two threads the upper thread and the lower thread, which is fed from a bobbin. The machine's needle punctures the fabric, drawing the upper thread through the material. Simultaneously, a hook mechanism catches the upper thread and wraps it around the lower thread, forming a lockstitch at the point of interlocking. This process is repeated rapidly, enabling operators to produce numerous stitches per minute, which is critical in high-volume production settings.

Advantages of Lockstitch Machines

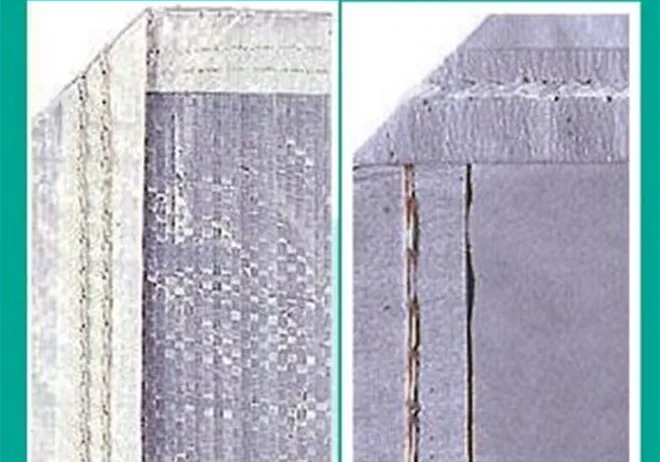

One of the primary advantages of lockstitch machines is their ability to create strong seams. The interlocking nature of the stitch makes it less likely to unravel, which is especially important for seams that experience tension, such as those found on heavily used garments or items like upholstery. Additionally, lockstitch machines are versatile and can handle a wide range of fabrics, from lightweight textiles to heavier materials.

industrial lockstitch machine

Furthermore, these machines are relatively straightforward to operate and maintain, which makes them accessible to a broad spectrum of users, from small workshops to large factories. The equipment is typically equipped with adjustable settings for stitch length and tension, allowing for customization based on specific project needs.

Technological Advancements

In recent years, advancements in technology have led to the development of more sophisticated lockstitch machines. Modern models are often equipped with computerized systems that enhance their functionality. Features such as automatic thread trimming, programmable stitch patterns, and advanced tension controls have improved efficiency and productivity in the workplace. Some even come with integrated sewing assistants that help reduce human error, thereby ensuring a consistent quality in the finished products.

Additionally, the integration of servo motors has made these machines more energy-efficient and quieter, greatly enhancing the working environment in factories and workshops. These innovations not only contribute to a smoother production process but also promote sustainability within the textile industry.

The Future of Lockstitch Machines

As the global demand for textiles continues to grow, the industrial lockstitch machine is poised to remain a key player in the manufacturing landscape. While automated sewing technology and robotics are on the rise, the reliability and efficacy of lockstitch machines ensure their relevance. Companies are likely to continue investing in advanced lockstitch technologies, enabling them to meet both quality standards and production demands in an increasingly competitive market.

In conclusion, the industrial lockstitch machine is more than just a tool; it is a vital element that supports the fabric of the textile industry. Through its historical significance, operational advantages, and continued evolution with technological advancements, it embodies the relationship between craftsmanship and innovation. As manufacturers strive to balance efficiency with quality, the lockstitch machine will undoubtedly play a central role in shaping the future of garment production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025