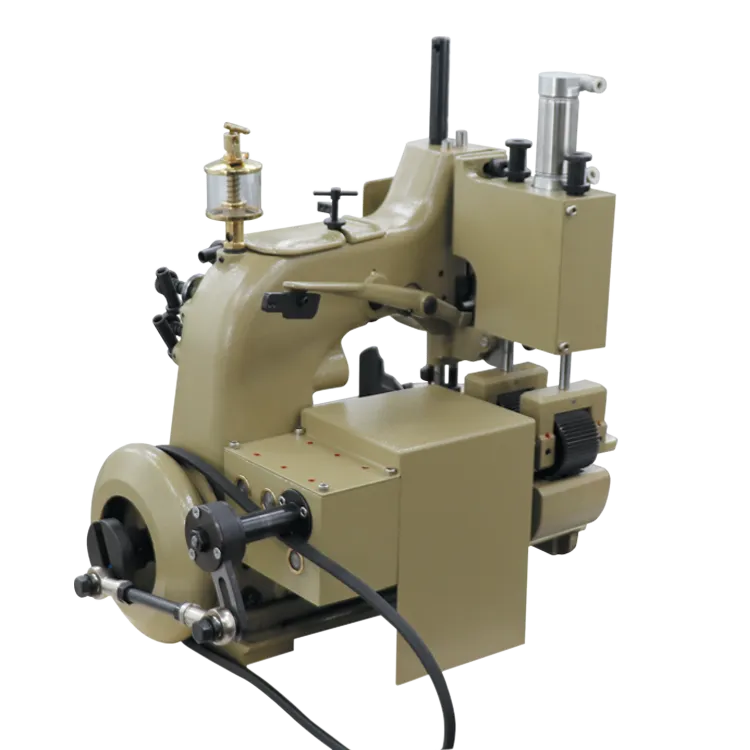

fibc twin needle machine

The FIBC Twin Needle Machine A Revolution in Textile Production

In the rapidly advancing world of textile production, the demand for efficient, durable, and high-quality manufacturing processes has never been greater. Among the innovative machines that have emerged to meet these demands is the FIBC (Flexible Intermediate Bulk Container) twin needle machine. This piece of equipment is revolutionizing the way bulk textiles, particularly in the manufacture of FIBCs and other woven products, are produced.

Understanding FIBCs

Flexible Intermediate Bulk Containers, or FIBCs, are large bags designed to hold and transport bulk materials. Commonly used in industries such as agriculture, construction, and food processing, these bags can carry everything from grains and chemicals to sand and fertilizers. The design and construction of FIBCs require precision and robust manufacturing capabilities, making the choice of machinery critical for producers.

The Role of the Twin Needle Machine

The FIBC twin needle machine is specifically engineered for sewing heavy-duty fabrics used in FIBCs. Traditional sewing machines often struggle with the thickness and strength of the materials involved, leading to inefficiencies and compromised product quality. The twin needle configuration allows for two lines of stitching in a single pass, significantly enhancing productivity. This dual-stitching approach provides added strength to seams, ensuring that the bags can withstand the rigors of transport and storage without failure.

Key Benefits of the FIBC Twin Needle Machine

1. Efficiency and Productivity The ability to sew two lines at once means that production times are cut significantly. Manufacturers can produce more bags per hour compared to single needle machines, thus reducing labor costs and increasing output. In an industry where time is money, this efficiency is a game changer.

fibc twin needle machine

2. Strength and Durability The use of twin needles allows for stronger seams, which is crucial for FIBCs designed to hold heavy materials. This durability minimizes the risk of seam failure during transport, which could lead to costly spills or damage.

3. Versatility While primarily designed for FIBCs, these machines can be adapted for various applications, including bags of different sizes and materials. This flexibility means that companies can invest in a single type of machine to handle multiple types of production, simplifying machinery requirements and maintenance.

4. User-Friendly Design Modern FIBC twin needle machines are equipped with advanced features such as automatic thread trimming, programmable sewing patterns, and ease of threading. These advancements make the machines easier to operate, reducing the training time for new operators and improving overall workplace efficiency.

5. Cost-Effectiveness Although the initial investment in a twin needle machine may be higher than that of traditional models, the long-term savings in labor and material costs, paired with increased output, justify the expense. Additionally, the durability of the seams produced leads to fewer returns and warranty claims.

Industry Impact

The introduction of the FIBC twin needle machine has had a profound impact on the textile manufacturing industry. Companies equipped with this technology can meet growing market demands while maintaining high standards of quality. Moreover, as sustainability becomes increasingly important, these machines are often designed to use eco-friendly materials and efficient manufacturing processes, minimizing waste.

Conclusion

As the textile industry continues to evolve, the role of innovative machinery like the FIBC twin needle machine becomes ever more critical. With its blend of efficiency, strength, and versatility, this machine is not just a tool but a catalyst for change in how textiles are produced. Manufacturers looking to enhance their operations should consider investing in such technology to stay competitive in a fast-paced market. Ultimately, the FIBC twin needle machine is not only shaping the future of textile manufacturing but is also setting new standards for quality and efficiency in the industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025