Double Walking Foot Sewing Machine - Precision and Performance for All Your Sewing Needs

Understanding the Double Walking Foot Sewing Machine

Sewing has evolved immensely over the years, and one of the remarkable advancements in the craft is the introduction of specialized sewing machines. Among them, the double walking foot sewing machine has gained significant popularity, particularly in the realms of upholstery, leatherworking, and heavy fabric sewing. This article explores the features, benefits, and applications of double walking foot sewing machines, highlighting why they are a staple for both professional and home sewists.

What is a Double Walking Foot Sewing Machine?

At its core, the double walking foot sewing machine is designed to handle difficult fabrics while providing superior feed and stitching accuracy. Unlike standard sewing machines that usually have a single feed mechanism, a double walking foot machine includes two walking feet—one on the top and one on the bottom. This unique feature ensures that multiple layers of fabric are fed through the machine evenly and smoothly, which is especially beneficial when working with heavy or slippery materials.

Key Features

1. Dual Feed Mechanism The double walking foot design allows for simultaneous feeding of the upper and lower layers of fabric. This prevents slipping and shifting, ensuring that seams are straight and aligned.

2. Heavy-Duty Construction These machines are typically built with sturdier materials. This construction not only helps them withstand the rigors of working with heavy fabric types, but also prolongs their lifespan.

3. Adjustable Stitch Length Many models feature adjustable stitch lengths, allowing users to customize their sewing according to the project requirements. This is particularly important when working with different fabrics and thicknesses.

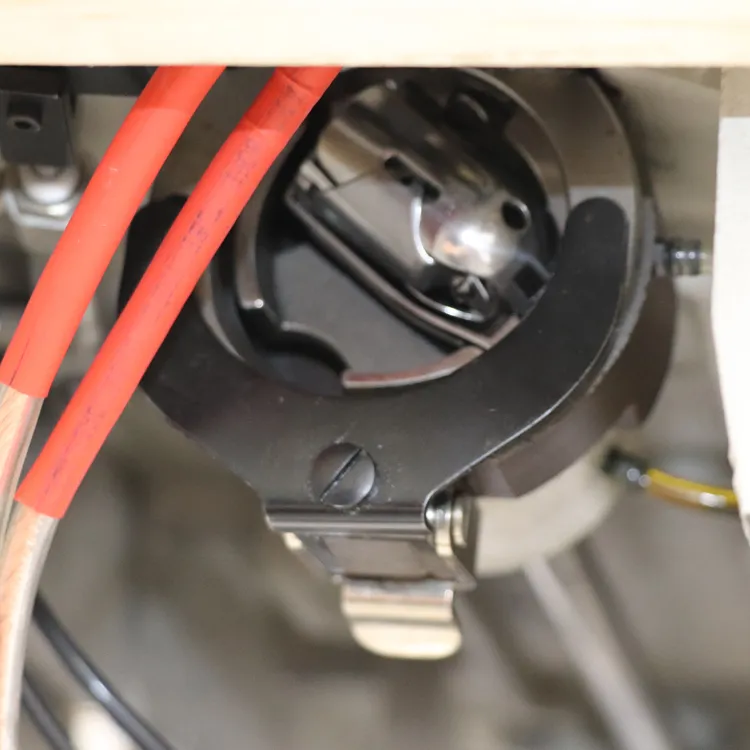

double walking foot sewing machine

5. Vertical Needle System Most double walking foot sewing machines utilize a vertical needle system, which enhances the precision of the stitching, especially when intricate details are needed.

Benefits of Using a Double Walking Foot Sewing Machine

One of the most significant advantages of using a double walking foot sewing machine is its ability to tackle challenging materials. Whether you are working with leather, canvas, or multiple layers of fabric, this machine ensures that everything feeds smoothly. It minimizes the risk of fabric bunching or puckering, which is a common problem experienced with standard machines.

This machine is also an excellent choice for quilting. Quilters appreciate how the dual feed system helps to manage the layers of fabric that often accompany quilt projects. It can handle the bulk of quilt sandwiches composed of batting, backing, and top layers seamlessly.

Additionally, the precision offered by double walking foot machines makes them ideal for delicate tasks such as topstitching and edge joining. Many professionals in the garment and upholstery industries rely on this type of sewing machine for its reliability and performance.

Applications

Double walking foot sewing machines are versatile and can be found in various industries. From fashion design to upholstery and crafting, they serve multiple purposes. Whether you are a beginner enthusiast looking to expand your sewing capabilities or a professional looking for a dependable machine for heavy-duty projects, a double walking foot sewing machine can significantly enhance your sewing experience.

In conclusion, the double walking foot sewing machine is an invaluable tool for anyone serious about sewing. Its ability to manage heavy and difficult fabrics while providing precision makes it a worthy investment for both hobbyists and professionals. As sewing continues to evolve, machines like these will undoubtedly play a critical role in pushing the boundaries of creativity and craftsmanship.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025