Versatile Chain and Coverstitch Machines for Professional Sewing Projects

Understanding Chain Stitch and Coverstitch Machines The Backbone of Garment Construction

In the world of garment making, the tools of the trade can greatly influence the quality and efficiency of the final product. Two essential machines that have become staples in the sewing industry are the chain stitch and coverstitch machines. Each serves a unique purpose and is integral to achieving professional finishes in a variety of garments.

Chain Stitch Machines Versatility and Speed

Chain stitch machines are designed to create a series of interlocked stitches that are both strong and flexible. The primary advantage of chain stitching is its speed; these machines can run at significantly higher speeds than traditional lockstitch machines. This makes them particularly useful in mass production, where efficiency is key.

The chain stitch is made by using a single needle that interlocks with one or more looper threads. This design allows for ease of stretching, making it an ideal choice for sewing areas that require flexibility, such as seams on t-shirts and elastic materials. Additionally, because chain stitches often do not require as much thread as lockstitches, they can reduce material costs in high-volume production runs.

Beyond garments, chain stitch machines are also used in the production of home textiles, such as curtains and bed linens, where efficient sewing and durability are vital. Their ability to create decorative stitches also opens up possibilities for embellishment in fashion design.

Coverstitch Machines Ensuring Professional Finishes

On the other hand, coverstitch machines are specifically designed to provide a professional and polished finish, particularly on knit fabrics. These machines typically feature multiple needles and a set of loopers that allow them to create a stitch that covers the seam, giving garments a clean, durable edge.

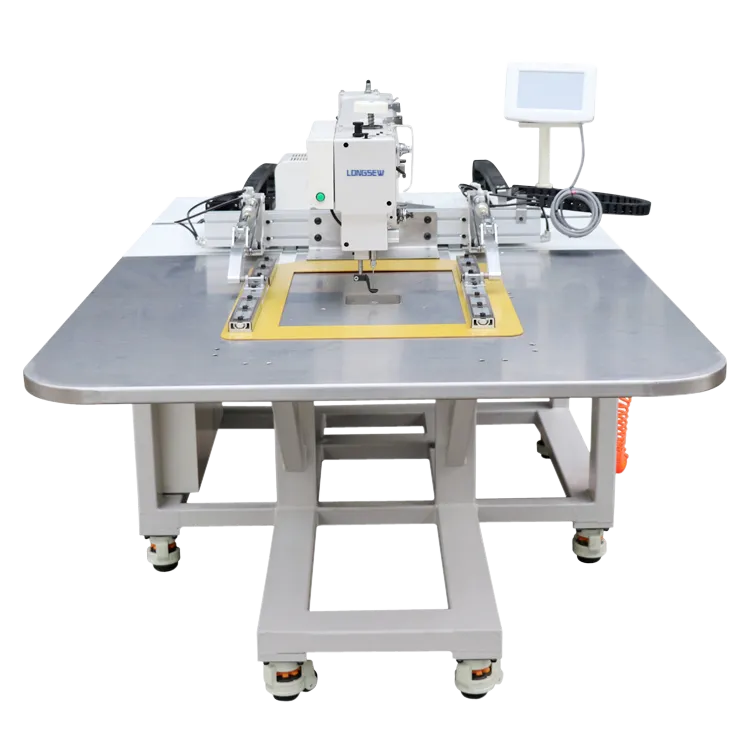

chain stitch coverstitch machine

A hallmark of coverstitching is its ability to stretch without breaking the seams, making it ideal for garments that require movement, such as sportswear, activewear, and lingerie. The coverstitch is commonly used for hems on t-shirts and leggings, as it not only secures the hem but also offers a nice aesthetic look due to its top and bottom stitch appearance.

Coverstitch machines also excel at creating decorative designs and can be adjusted to produce different styles of stitches depending on the project needs. This versatility allows designers to incorporate unique design elements while ensuring the garment remains functional and comfortable for the wearer.

Integrating Both Machines in Production

In many production environments, you’ll find both chain stitch and coverstitch machines working side by side. Using them in tandem allows for the efficient construction of garments that are not only strong and functional but also stylish and appealing.

For instance, a t-shirt might be assembled using a chain stitch for the main seams, allowing for quick assembly, while the hems are finished with a coverstitch, ensuring durability and a polished look. This combination leverages the strengths of both types of machines, resulting in a high-quality final product that meets consumer expectations.

Conclusion

In summary, both chain stitch and coverstitch machines play critical roles in garment production. Their unique capabilities cater to different aspects of sewing, from constructing durable seams to ensuring aesthetically pleasing finishes. As the fashion and textile industries continue to evolve, these machines will remain indispensable tools for achieving quality and efficiency in garment making.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025