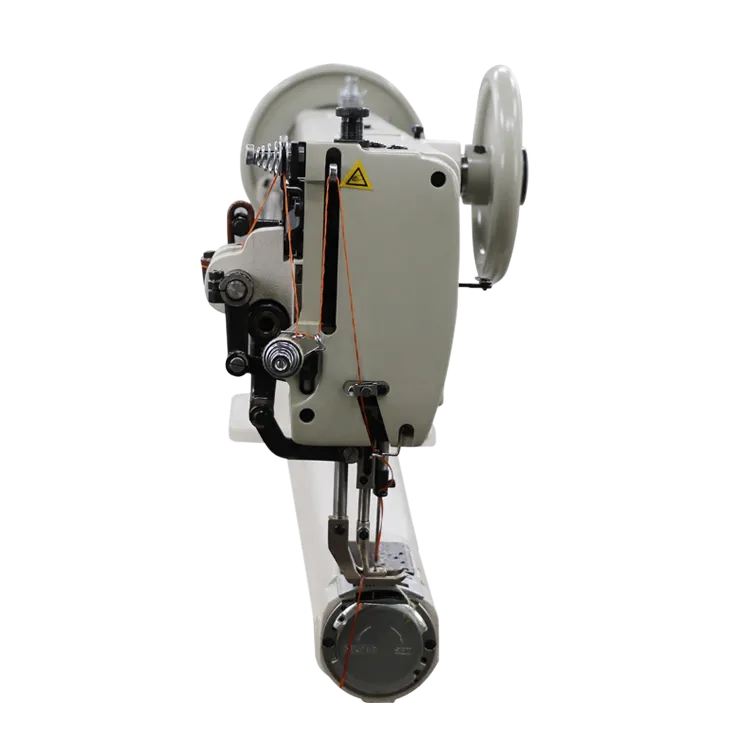

boot patcher sewing machine

The Evolution and Importance of Boot Patcher Sewing Machines

In the realm of industrial sewing, the Boot Patcher Sewing Machine stands as a remarkable innovation tailored specifically for the footwear industry. Designed to mend and repair various types of boots—from rugged work boots to fashionable leather designs—these specialized machines have transformed the way shoemakers and repair shops operate, ensuring durability and longevity in footwear.

Historical Context

The invention of the sewing machine in the 19th century marked a monumental shift in manufacturing and craftsmanship. As the demand for high-quality footwear grew, so did the need for efficient and specialized tools. Early shoemakers relied heavily on manual stitching techniques, which were labor-intensive and time-consuming. The advent of the Boot Patcher Sewing Machine heralded a new era, simplifying the repair process and allowing craftsmen to focus on quality rather than solely on manual labor.

Features and Functionality

Boot Patcher Sewing Machines are engineered with unique features that cater to the requirements of boot manufacturing and repair. One of the primary components is the walking foot mechanism, which allows for even feeding of multiple layers of thick material—essential when dealing with heavy leathers and synthetic fabrics. This feature ensures that seams are tight and consistent, minimizing the risk of wear and tear.

Moreover, these machines often come with adjustable stitch lengths, enabling artisans to choose the most suitable stitch type for different materials and tasks. From straight stitches for basic seams to more complex zig-zag patterns for added strength, the versatility of the boot patcher is a significant advantage.

In addition, many modern machines are equipped with automated features such as thread trimming and programmable patterns, allowing for increased efficiency and precision. This technology not only speeds up production but also enhances the quality of the finished product, meeting the higher standards of today's consumers.

boot patcher sewing machine

The Role of Boot Patcher Sewing Machines in Footwear Repair

For shoemakers, the Boot Patcher Sewing Machine is indispensable. Repairing damaged boots is an art form that requires both skill and the right tools. This machine allows for quick patching of worn-out areas, replacement of eyelets, and even re-stitching seams that have come undone. By providing a reliable method of repair, it helps extend the life of footwear, promoting sustainability in an age of fast fashion.

Additionally, the ability to offer high-quality repairs can set a shoemaker apart in a competitive market. Customers increasingly seek services that not only fix their beloved footwear but also preserve its character and charm. The boot patcher empowers these artisans to provide such services, maintaining the integrity of the shoes while enhancing their overall aesthetic.

Economic Impact

The implications of using Boot Patcher Sewing Machines extend beyond individual shoemakers. In a broader economic context, they contribute to the longevity of products, thus promoting sustainable consumer habits. As society becomes increasingly aware of environmental issues, the ability to repair rather than replace becomes vital. This shift not only reduces waste but also supports local businesses, fostering a more sustainable economy.

Moreover, in regions where artisanal craftsmanship is a hallmark of economic success, implementing efficient sewing technology like the boot patcher can bolster job creation and preservation of traditional skills. The balance between modern technology and age-old techniques can yield quality outputs that attract both local and international markets.

Conclusion

In the world of footwear manufacturing and repair, the Boot Patcher Sewing Machine is an essential tool that embodies the intersection of technology and craftsmanship. Its evolution has revolutionized the industry, allowing for quicker repairs and higher-quality production. As the global consciousness shifts towards sustainability and the value of artisanal skills, the importance of such machines will only continue to grow. Embracing this technology not only honors the legacy of shoemaking but also paves the way for future innovations in maintaining and enhancing the footwear we wear.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025