bag making machinery

The Evolution of Bag-Making Machinery

In the fast-paced world of manufacturing, the production of bags has become a critical aspect of various industries, from retail to industrial packaging. As consumer demands grow and environmental regulations tighten, the need for efficient, versatile, and sustainable bag-making machinery has surged. This article delves into the evolution of bag-making machinery, exploring its significance, advancements, and future prospects.

Historically, bag-making began as a manual process, where artisans skillfully crafted bags from natural fibers. However, as economies industrialized in the late 19th and early 20th centuries, the demand for bags surged, leading to the development of machinery designed to automate some of these processes. Early bag-making machines were simple, primarily focused on producing paper and basic fabric bags. These machines laid the groundwork for the sophisticated technology we see today.

The Evolution of Bag-Making Machinery

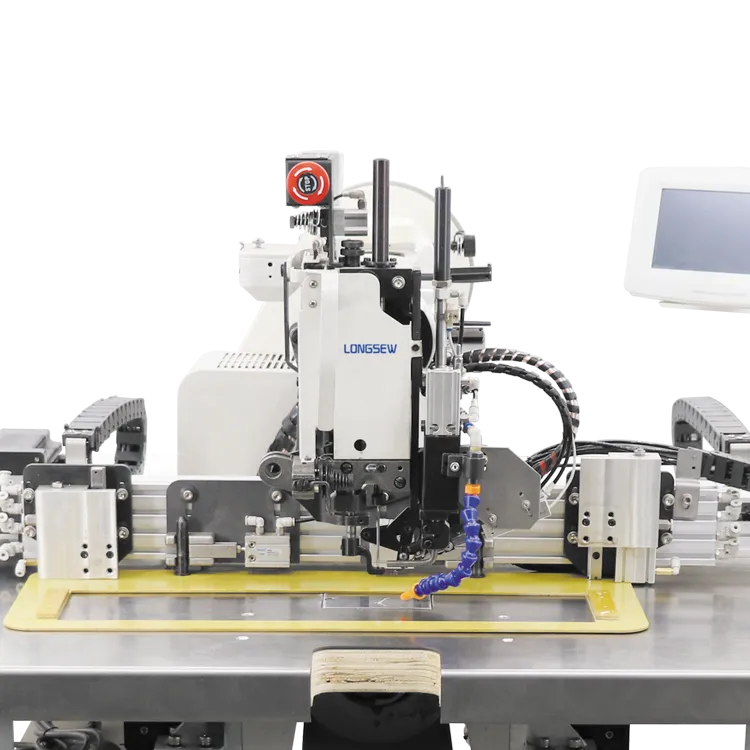

Modern bag-making machinery is characterized by its automation and efficiency. State-of-the-art machines are equipped with advanced features such as computer numerical control (CNC), servo motors, and high-speed production capabilities. These innovations enable manufacturers to produce bags with precision and speed, significantly reducing labor costs and increasing output. For instance, some machines can produce thousands of bags per hour, with minimal human intervention required.

bag making machinery

Moreover, as the global community becomes increasingly aware of environmental issues, bag-making machinery has adapted to meet the growing demand for sustainable packaging solutions. Manufacturers are now producing biodegradable bags and reusable fabric bags, and machinery has been developed to accommodate these eco-friendly materials. This shift not only addresses environmental concerns but also appeals to a consumer base that increasingly prioritizes sustainability.

In addition to sustainability, customization has become a significant trend in the bag-making industry. Consumers are looking for products that reflect their personal style or branding. Modern bag-making machinery can be programmed to produce bags of various sizes, colors, and prints on-demand, facilitating a high level of customization. Digital printing technology integrated into bag-making machines allows for intricate designs and logos to be printed directly onto the bags, enhancing brand visibility.

As we look to the future, the bag-making industry is poised for further innovation. Trends such as automation, Industry 4.0, and the Internet of Things (IoT) are set to redefine bag production. Smart machinery that can communicate with other devices and monitor production in real-time will optimize efficiency and reduce waste. Additionally, advancements in artificial intelligence may lead to predictive maintenance, ensuring that machines operate at peak performance.

In conclusion, the evolution of bag-making machinery reflects the broader trends in manufacturing and consumer behavior. From humble beginnings to high-tech automation, the industry has continually adapted to meet the demands of a changing world. As sustainability and customization take center stage, manufacturers that embrace innovation will thrive in the competitive landscape ahead. The future of bag-making machinery promises to be exciting, with endless possibilities for efficiency, creativity, and environmental stewardship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025