bag closer sewing machine for sale

The Market for Bag Closer Sewing Machines A Comprehensive Overview

In today's fast-paced manufacturing and retail environment, efficiency and quality are paramount. One essential piece of machinery that significantly contributes to this goal is the bag closer sewing machine. As businesses and individual entrepreneurs continue to explore opportunities in packaging and production, there is a growing demand for bag closer sewing machines, leading to a vibrant market for these specialized tools.

What is a Bag Closer Sewing Machine?

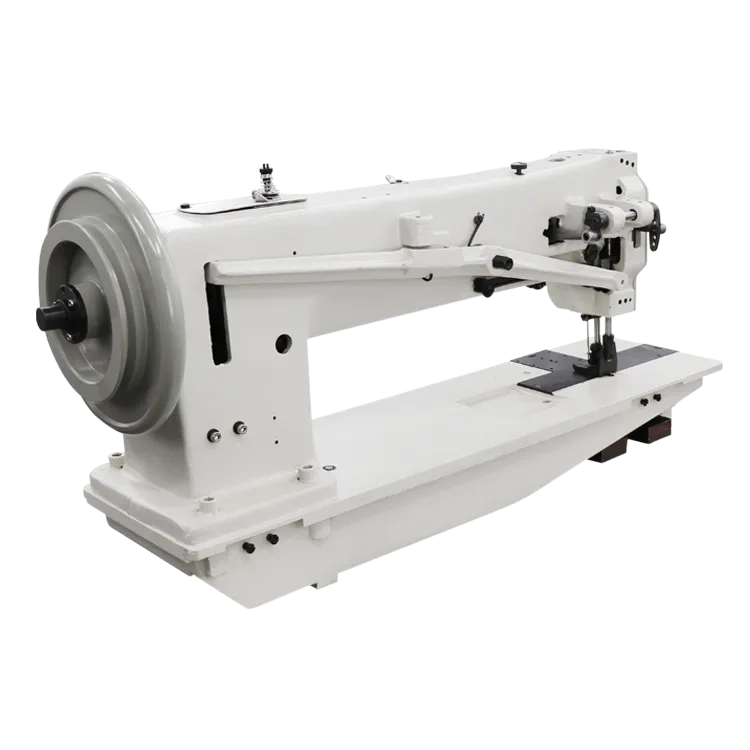

A bag closer sewing machine is a specialized device designed to securely sew the open ends of bags, typically made from materials like polypropylene, paper, or cotton. These machines are essential for businesses in various industries, including agriculture, food processing, construction, and retail, as they enable them to package products efficiently and reliably.

These machines come in several variants, including portable models for small-scale operations and heavy-duty models for large-scale industrial use. Common features include adjustable stitch length, built-in thread tension controls, and robust needle mechanisms that enable them to handle different bag types and thicknesses.

The Importance of Bag Closers in Industry

Efficient packaging plays a crucial role in overall productivity, product integrity, and customer satisfaction. Bag closer sewing machines provide a secure closure that prevents spillage or contamination, which is especially vital in sectors like food and pharmaceuticals. Additionally, the ability to produce consistent, professional-quality closures helps brands maintain their reputation and meet regulatory requirements.

Key Features to Look For

When considering purchasing a bag closer sewing machine, there are several features to keep in mind

1. Type of Machine Depending on your needs, you can choose between electric, pneumatic, or manual machines. Electric machines are faster and more efficient, while pneumatic machines offer precision and are ideal for high-volume tasks.

bag closer sewing machine for sale

2. Speed Look for a machine that offers adjustable speed settings to match your production pace. High-speed models can significantly increase output but require more skill to operate effectively.

3. Durability Given the often rigorous working conditions, it is essential to invest in a machine made from high-quality materials that can withstand frequent use.

4. Stitch Quality The ability to produce strong, even stitches is vital for the purpose of securing bags. Checking the stitch quality during a demonstration can be enlightening.

5. Ease of Use and Maintenance A user-friendly design simplifies training new operators and ensures that maintenance can be performed with minimal downtime.

6. Portability If you need to move your machine between different locations, consider a lightweight, portable model.

7. Cost Prices for bag closer sewing machines can vary significantly based on capabilities and features. It's vital to balance cost with the machine's long-term reliability and efficiency.

Where to Buy

The marketplace for bag closer sewing machines is diverse, with options from local suppliers, online retailers, and industry-specific manufacturers. Websites like Alibaba, Amazon, and eBay offer numerous models at competitive prices. Additionally, attending trade shows and industry expos can provide opportunities to see machines in action, compare features, and negotiate with suppliers.

Conclusion

The demand for bag closer sewing machines continues to grow as businesses seek to enhance their packaging capabilities. By understanding the critical features and assessing specific operational needs, companies can select the right machine that boosts productivity and maintains the quality of their products. In a world where first impressions matter—especially in product packaging—the right bag closer sewing machine is not just a tool but a pivotal investment towards achieving business success. Whether you are part of a large manufacturing plant or a small startup, investing in a reliable bag closer sewing machine can streamline operations and ensure product integrity from production to delivery.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025